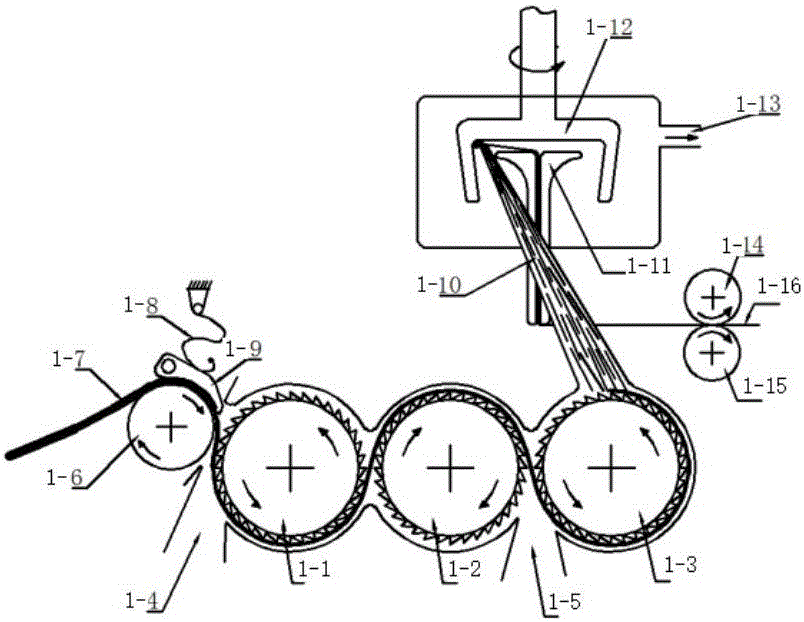

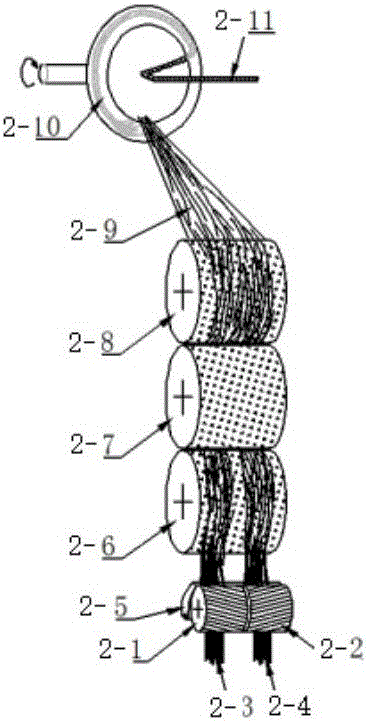

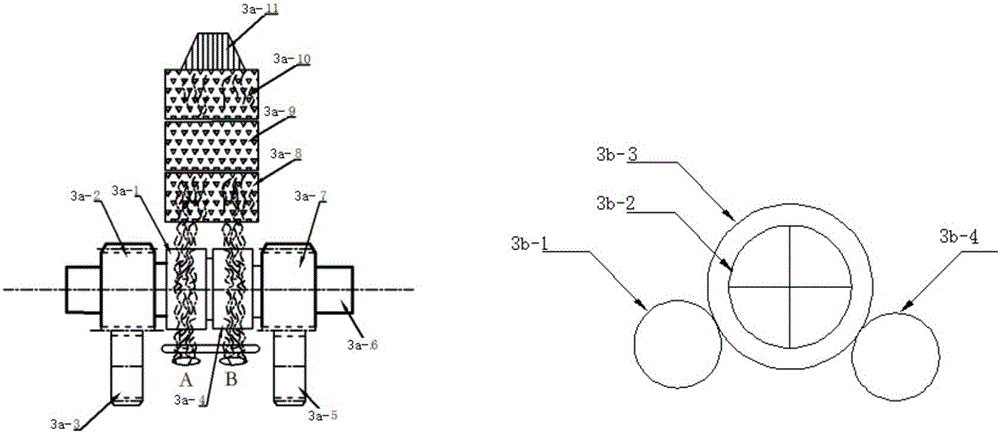

Double-sliver asynchronous feeding and three-level carding rotor spinning method and device

An asynchronous input, three-stage technology, applied in the direction of continuous winding spinning machine, spinning machine, open-end spinning machine, etc., can solve the problems of not given, blocked rotor cup, blocked carding roller, etc. Achieve the effects of good carding and transfer, optimization of longitudinal orientation, and speed improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Spinning process design:

[0026] V 01 : Line speed of cotton roller 1; V 02 : Line speed of cotton roller 2; V 1 : linear speed of opening roller 1;

[0027] V 2 : line speed of opening roller 2; V 3 : line speed of opening roller 3; V 4 : Linear speed of rotor; V 5 : Line speed of drawing roller;

[0028] ρ 1 :: linear density of sliver A (gram weight / m);

[0029] ρ 2 : linear density of sliver B (gram weight / meter);

[0030] ρ: Yarn density (gram weight / meter);

[0031] ρ 11 : the linear density (gram weight / meter) of sliver A passing through opening roller 1;

[0032] ρ 12 : the linear density (gram weight / meter) of sliver A through opening roller 2;

[0033] ρ 13 : the linear density (gram weight / meter) of sliver A through opening roller 3;

[0034] ρ 14 : linear density of sliver A in the rotor (gram weight / m),

[0035] ρ 21 : the linear density (gram weight / meter) of sliver B passing through opening roller 1;

[0036] ρ 22 : the linear densi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com