Walking type pile testing machine

A walking and pile-testing technology, which is applied in the test of foundation structure, construction, foundation structure engineering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

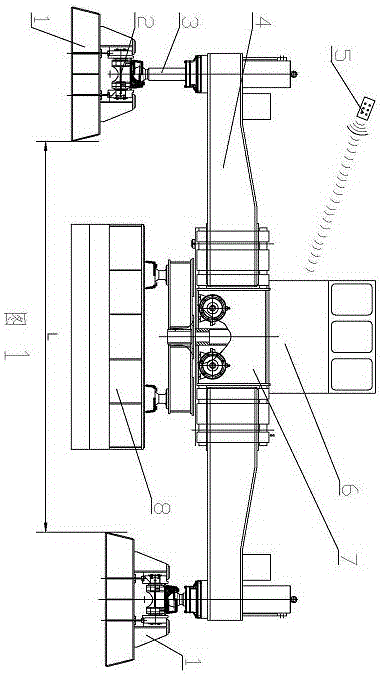

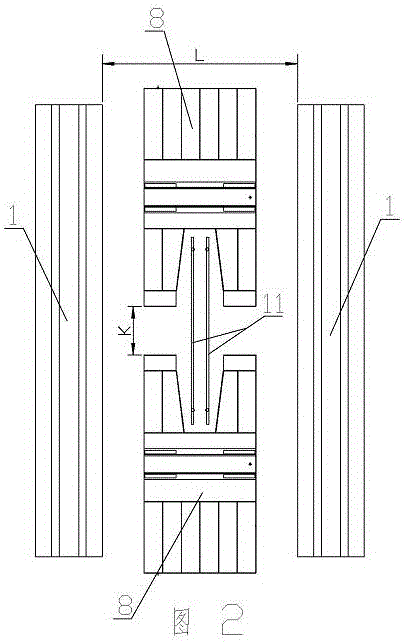

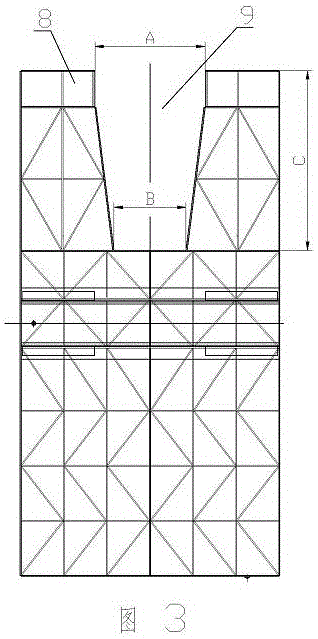

[0021] exist figure 1 In the walking pile measuring machine shown, the load-bearing platform 7 adopts a rectangular box-slab structure, and four long ship support beams 4 are arranged on both sides of the load-bearing platform 7 to extend outward. Such as figure 2 As shown, two long boats 1 are arranged in parallel on both sides of the load-bearing platform 7, and two short boats 8 are arranged at both ends of the load-bearing platform 7, and are fixedly installed at the positions of the reference beam gaps 9 opposite to the two short boats 8. There is a detection reference beam 11 for installing the displacement sensor, and the detection reference beam 11 is installed in the soil layer of the pile foundation through its fixed pile.

[0022] The outer ends of the two longship support beams 4 on the same side of the load-bearing platform 7 are equipped with oil cylinder supports 3, and the lower ends of the oil cylinder supports 3 are supported on the longboat traveling vehi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com