Impact drill bit of full-hydraulic reverse circulation drilling machine

An impact drill bit and reverse circulation technology, applied in drill bits, drilling equipment, earthwork drilling and other directions, can solve the problems of inability to achieve drilling operations, difficulty in drilling rock layers, large drill bit torque, etc., achieving good results and solving drill pipe problems. Damage, fast drilling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

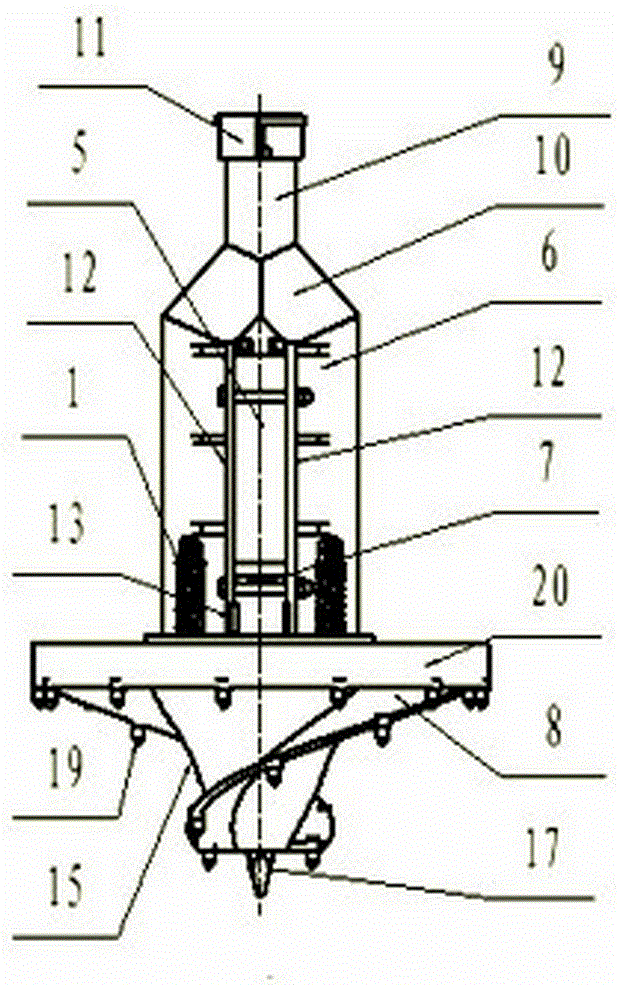

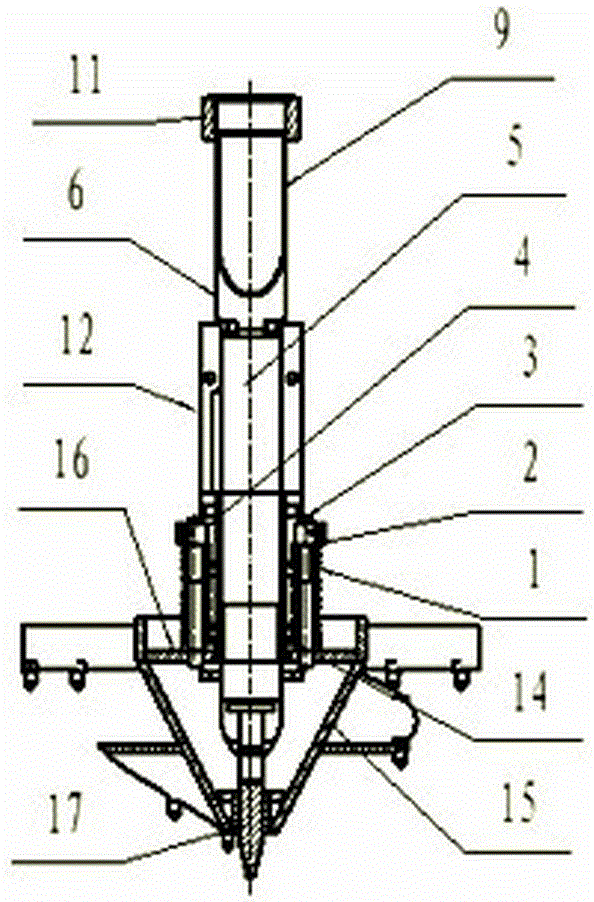

[0024] Embodiment 1 A percussion drill for a full hydraulic reverse circulation drilling rig includes a compression spring 1, a spring positioning sleeve 2, a stud 3, a lock nut 4, an impactor 5, a feed pipe weldment 6, a bolt 7, and a drill weldment piece 8 (eg Figure 1-9 shown);

[0025] a. Install the lower ends of the four studs 3 respectively in the four holes on the two connecting plates 16 of the drill weldment 8 and weld them ( figure 2 , Figure 6 );

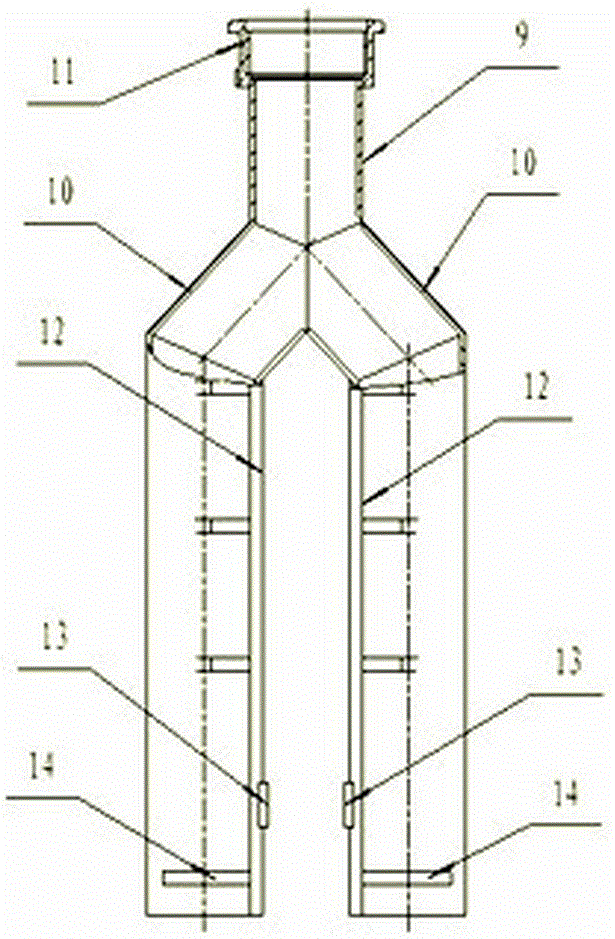

[0026] b, the impactor 5 is a rectangular cylinder, the bottom of its two opposite faces each has a transverse rectangular groove 22, the lower end has a vibrating head 23, the interior of the impactor 5 is equipped with a motor, the motor The oil inlet 24 and the oil outlet 25 are on its top; when the motor was working, it drove the vibration head 23 to vibrate at high frequency up and down (as Figure 8 , Figure 9 shown);

[0027] The rectangular groove 22 is engaged with the two convex limit plates 13 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com