Filter and laser printing manufacturing method and application thereof

A laser printing and filter technology, which is applied in the direction of mechanical equipment, machine/engine, engine components, etc., can solve problems such as failure, cumbersome process, and limited preparation conditions, so as to meet the use requirements, prolong the service life, and improve the filtering effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

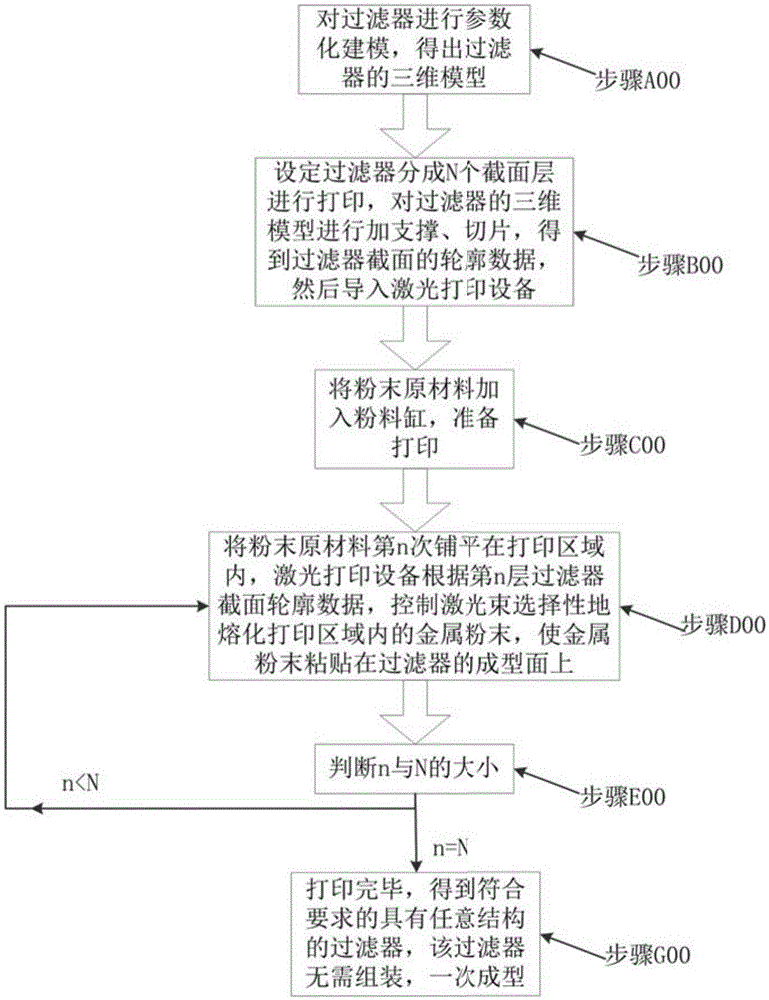

[0029] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0030] Selective Laser Melting (SLM) technology, also known as "metal 3D printing technology", is the cutting-edge technology of additive manufacturing. It uses a focused laser beam with a diameter of 30 to 50 microns to melt metal or alloy powder layer by layer and accumulate it into a metallurgical process. Combined and densely organized solids to obtain metal functional parts with almost any shape and complete metallurgical bonding.

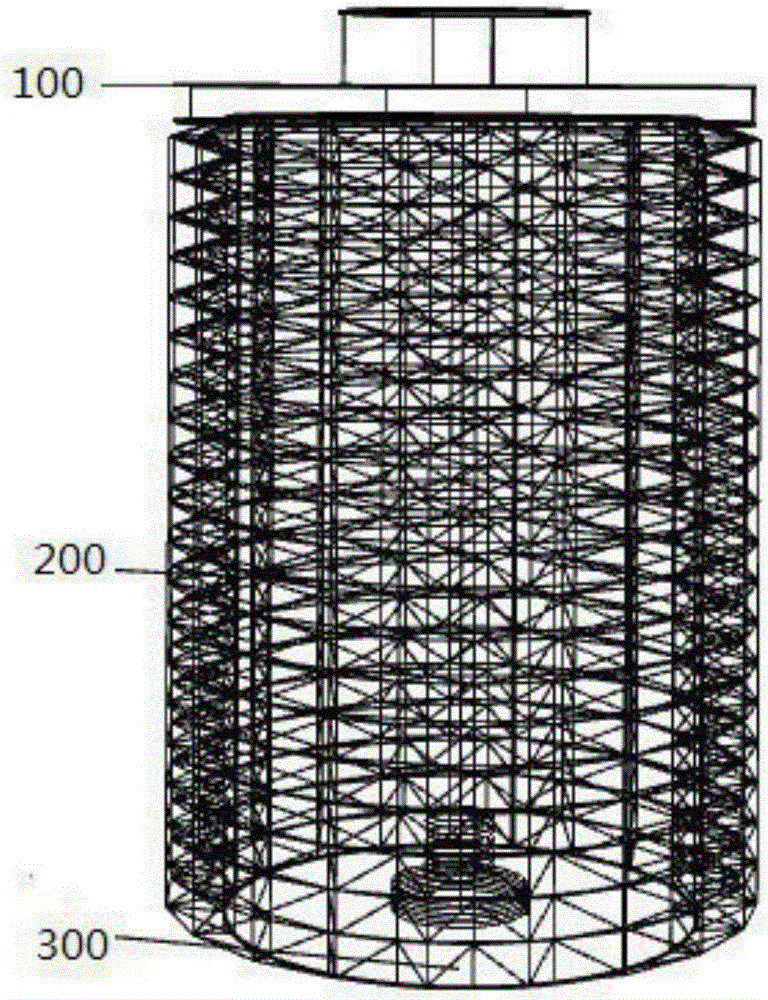

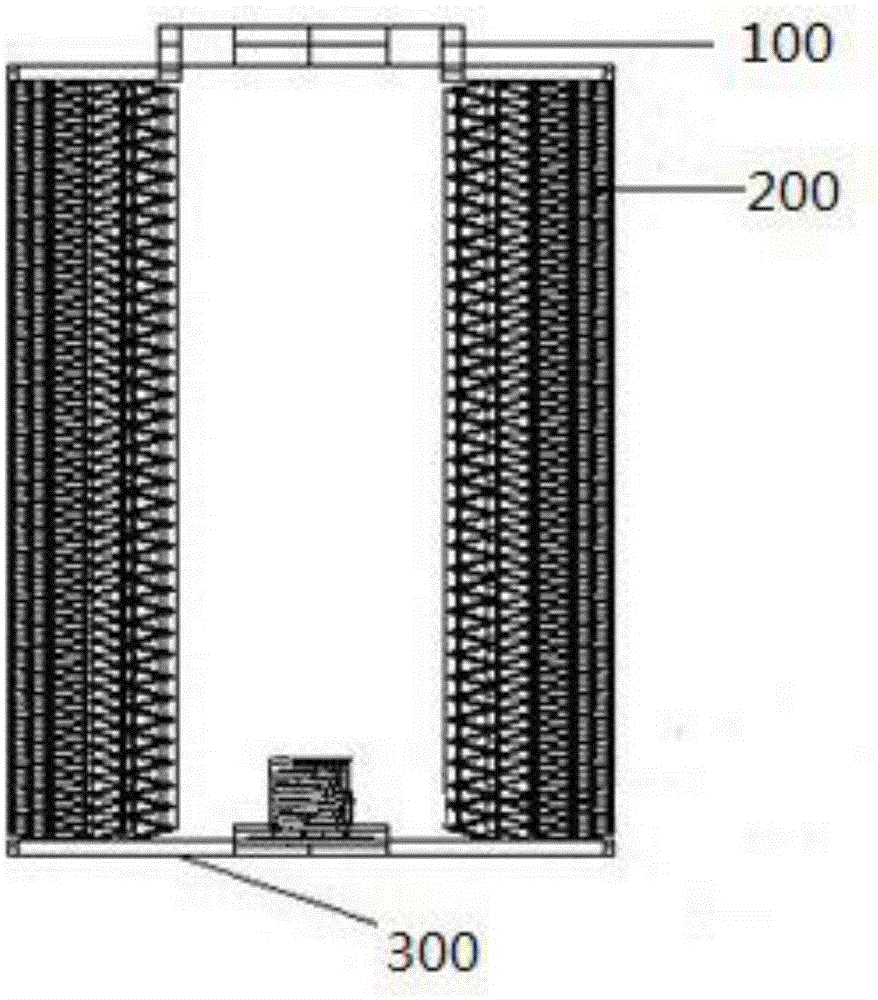

[0031] Such as figure 1 with figure 2 As shown, the filter is formed by metal 3D laser printing equipment according to the cross-sectional profile data of the filter, controlling the laser beam to selectively melt the metal powder of each layer and gradually stacking; the filter includes an upper metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com