A Method for Determining the Air-Oil Ratio of the Drying Tube Burner of Asphalt Mixing Equipment

A technology of asphalt mixture and mixing equipment, which is applied in the direction of burners, lighting and heating equipment, etc. It can solve the problems of energy waste, difficulty in ensuring equipment operation, and low thermal efficiency, so as to reduce production costs, fast test speed, and reduce carbon emissions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

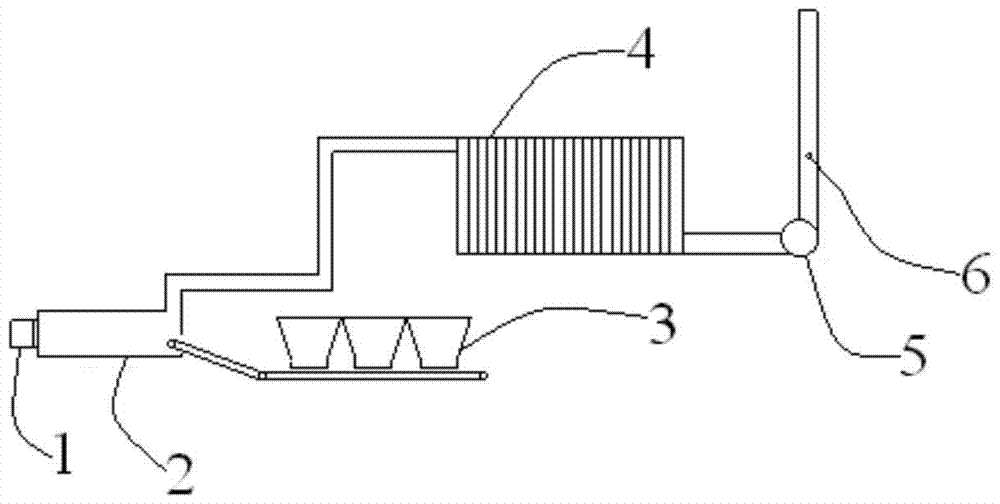

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

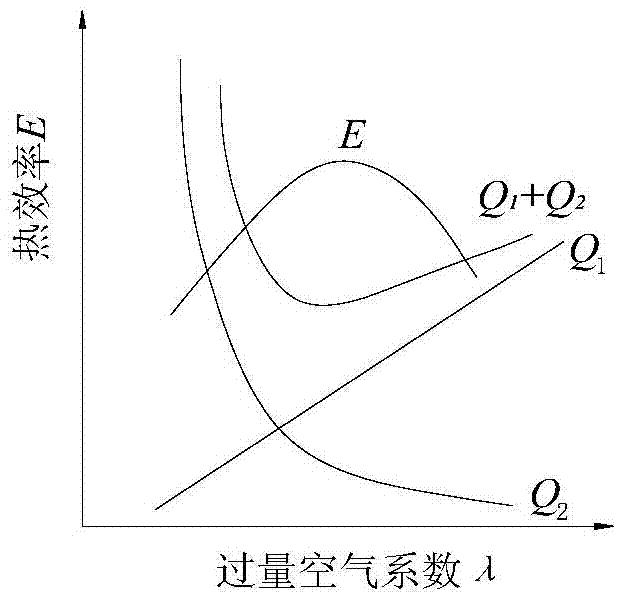

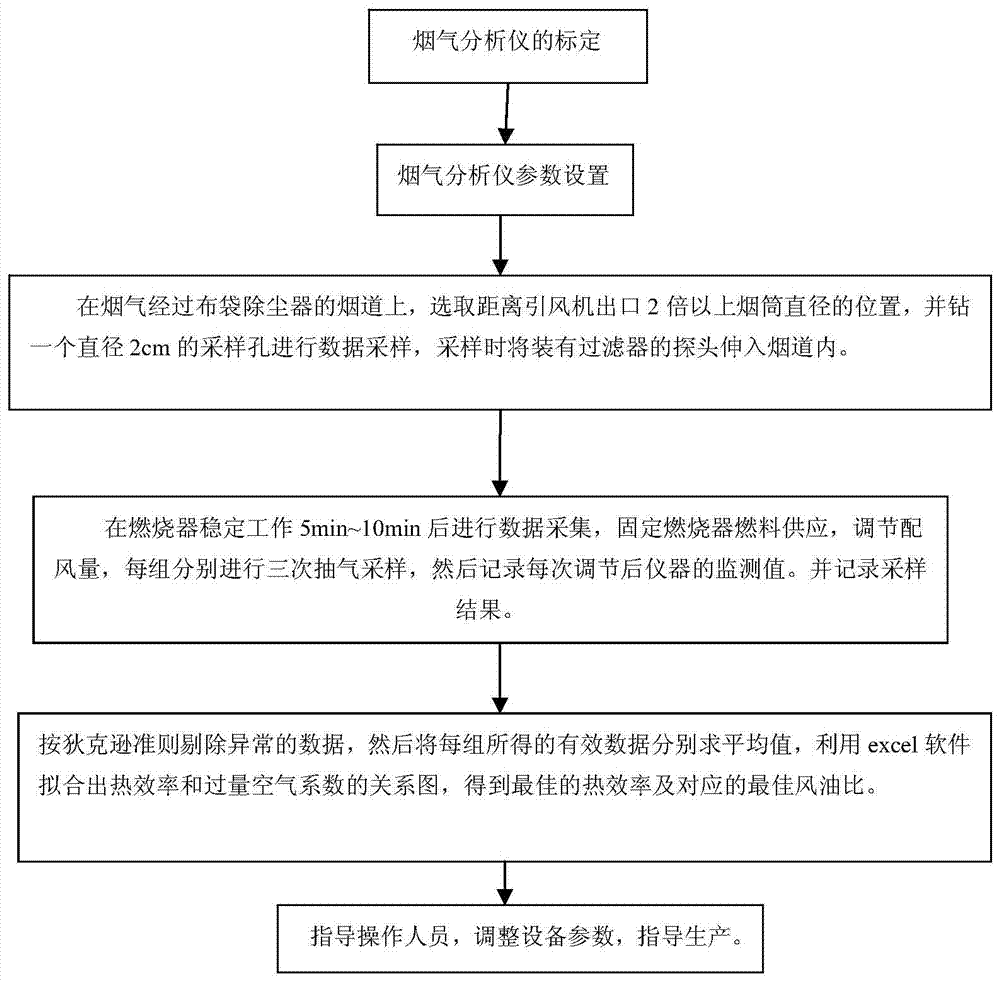

[0021] see figure 1 , the prior art research shows that the thermal efficiency of the burner can be improved by the O in the flue gas 2 , CO 2 , CO content, and exhaust gas temperature are obtained indirectly, and the thermal efficiency is determined by the burner air-oil ratio (oil-gas mixing conditions). Therefore, a flue gas analyzer can be used to measure the content of each component in the flue gas discharged from the asphalt mixing plant, and the air-oil ratio of the burner can be adjusted according to the measured results to obtain the working parameters with the highest thermal efficiency.

[0022] Thermal efficiency is an important index to evaluate the heating performance of the drying cylinder burner. The thermal efficiency of the burner in the asphalt mixing plant can be calculated by formula (1):

[0023]

[0024] In the formula: E—thermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com