Three-dimensional while-drilling induced polarization rock precise imaging device and method

A technology for stimulating polarization and imaging devices, which is applied in the direction of electric/magnetic detection for well logging records, can solve problems such as time-consuming, low efficiency, and failure to display detection results, so as to improve work efficiency and solve technical problems. Bottleneck, the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

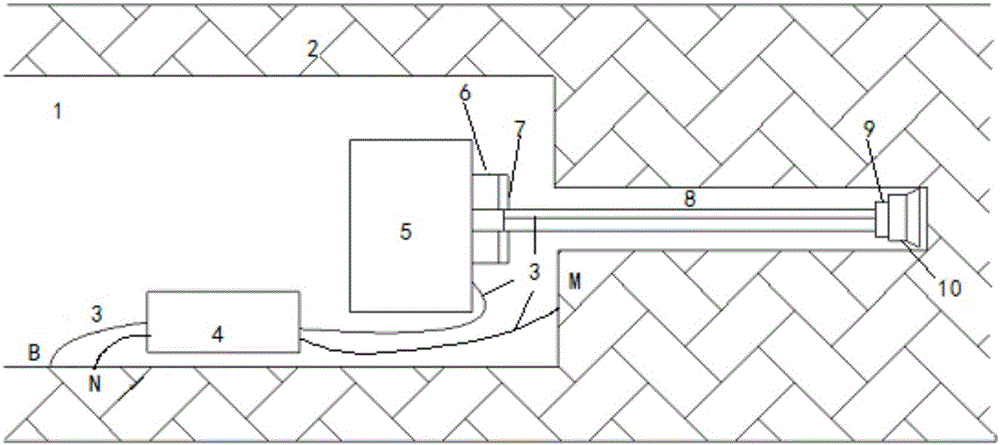

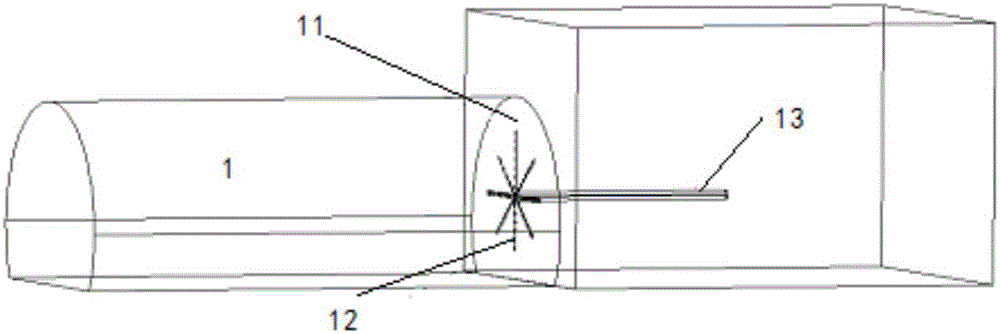

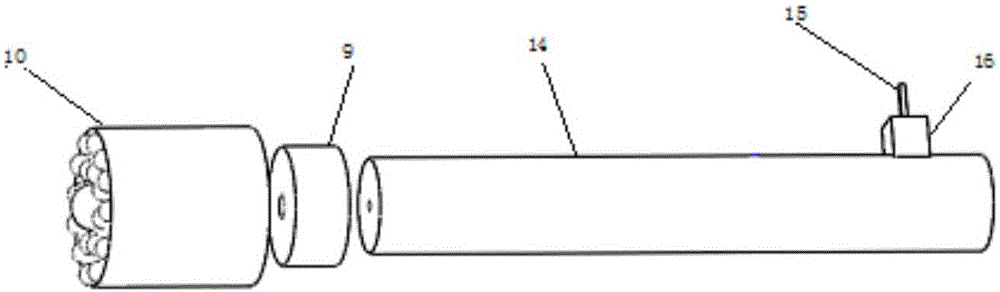

[0055] figure 1 This is a schematic diagram of the detection method and instrument installation structure, which is mainly composed of the power supply system while drilling, the power supply electrode cable 3 and its rotating device, the positioning device of the drill bit 10, the three-dimensional array measuring electrode system, the controller and the real-time inversion imaging system. The drill bit 10 is connected to the drill rod 8 through a double-sided insulation device, the drill rod 8 is connected to the drill rig 5, the conductive slip ring 7 is fixed on the drill rig bracket 6, one end of the cable 3 is connected to the drill bit 10 through a quick joint, and the other end is connected to the drill rod 8 The spring pressing piece 15 at the tail is connected, and the spring pressing piece 15 is connected with the conductive slip ring 7, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com