Self-calibrated driving circuit of light-emitting diode (LED) corridor lighting system

A lighting system and driving circuit technology, which is applied to lighting devices, lamp circuit layout, electric light sources, etc., can solve problems such as EMI interference and low power utilization, and achieve the effects of reduced power consumption, low power consumption, and simple circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

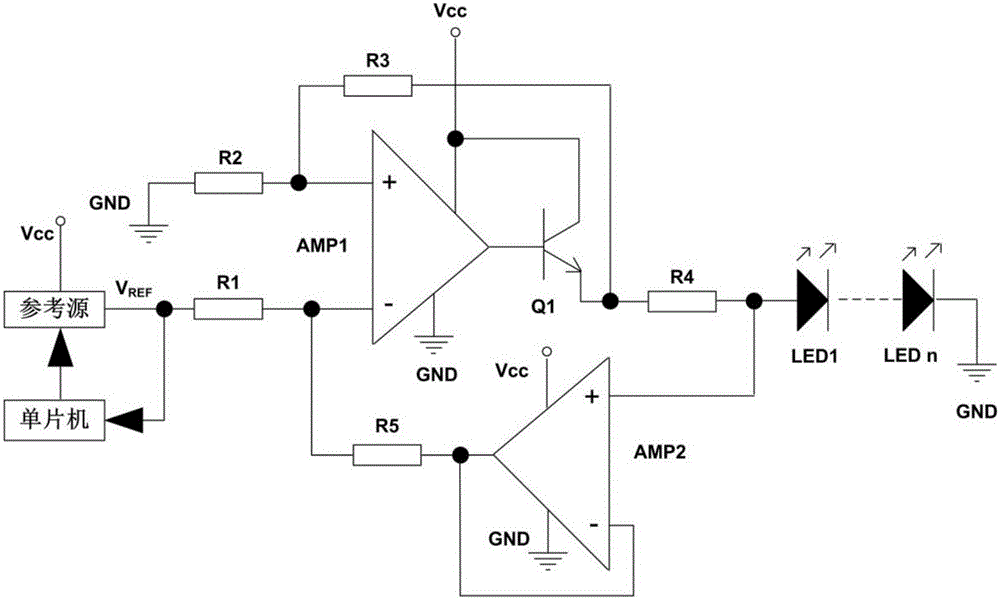

[0025] figure 1 It is a schematic circuit diagram of the driving circuit of the self-calibrating LED corridor lighting system described in Embodiment 1 of the present invention. It can be seen from the figure that the driving circuit of the self-calibrating LED corridor lighting system includes: a reference source for providing a reference voltage for the LED corridor lighting system, a first operational amplifier AMP1, a second operational amplifier AMP2, a first resistor R1, a second resistor R2, a third resistor R3, a fourth resistor R4, a fifth resistor R5, a transistor Q1, a plurality of LED lamps connected in series in the same direction, and a single chip microcomputer.

[0026] The same input end of the first operational amplifier AMP1 is respectively connected to one end of the second resistor R2 and one end of the third resistor R3, and the other end of the second resistor R2 is grounded; the inverting input end of the first operational amplifier AMP1 passes through ...

Embodiment 2

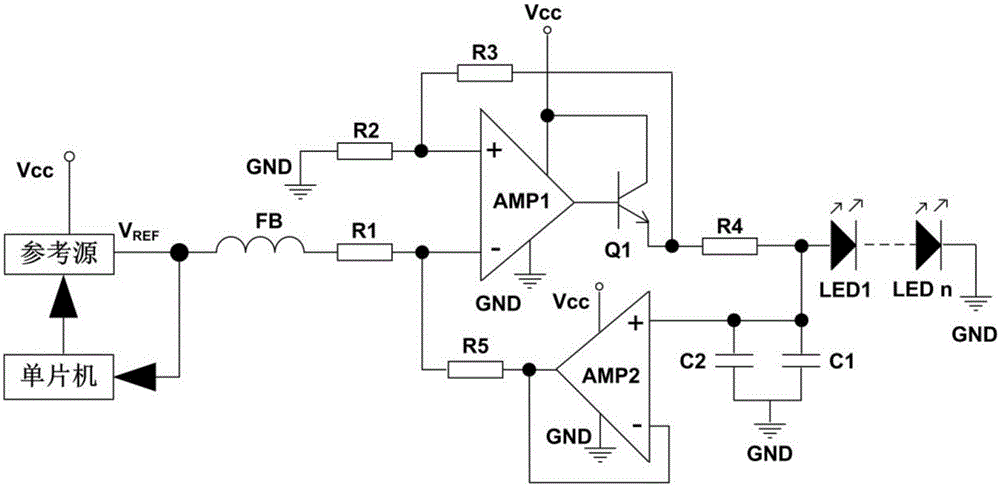

[0031] The driving circuit of the self-calibrating LED corridor lighting system provided in this embodiment is different from Embodiment 1 in that the driving circuit of the self-calibrating LED corridor lighting system also includes a magnetic bead FB, such as figure 2 As shown, one end of the magnetic bead FB is connected to the output end of the reference source, and the other end is connected to one end of the first resistor R1, which has the advantages of suppressing high-frequency noise and spike interference at the output end of the reference source and absorbing electrostatic pulses.

[0032]As another implementation of this embodiment, the drive circuit of the self-calibrating LED corridor lighting system further includes a first capacitor C1 and a second capacitor C2, and the other end of the fourth resistor R4 passes through one end of the first capacitor C1, the second capacitor One end of the second capacitor C2 is connected to the non-inverting input end of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com