High-precision printed circuit board

A printed circuit board, high-precision technology, applied in the direction of printed circuits, printed circuit components, circuit heating devices, etc., can solve the problems that cannot be realized, the automatic detection system is expensive, and cannot be inspected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

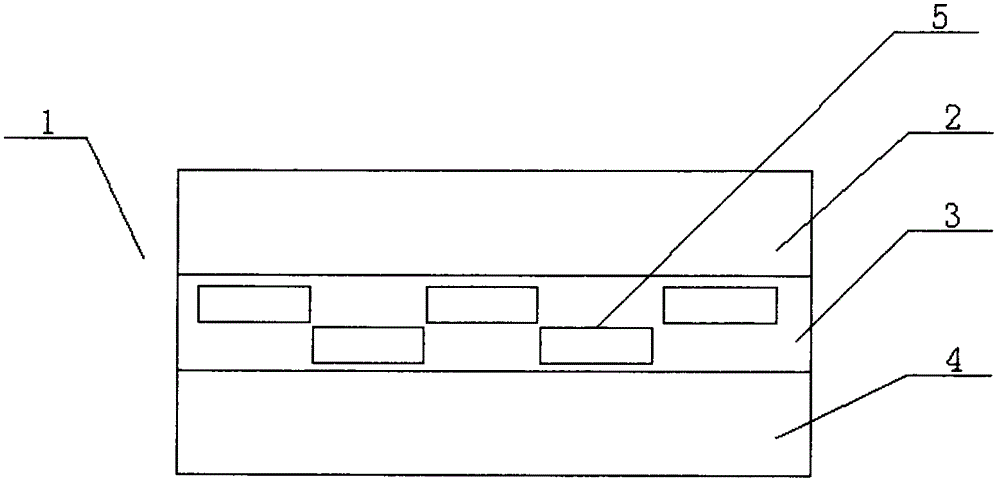

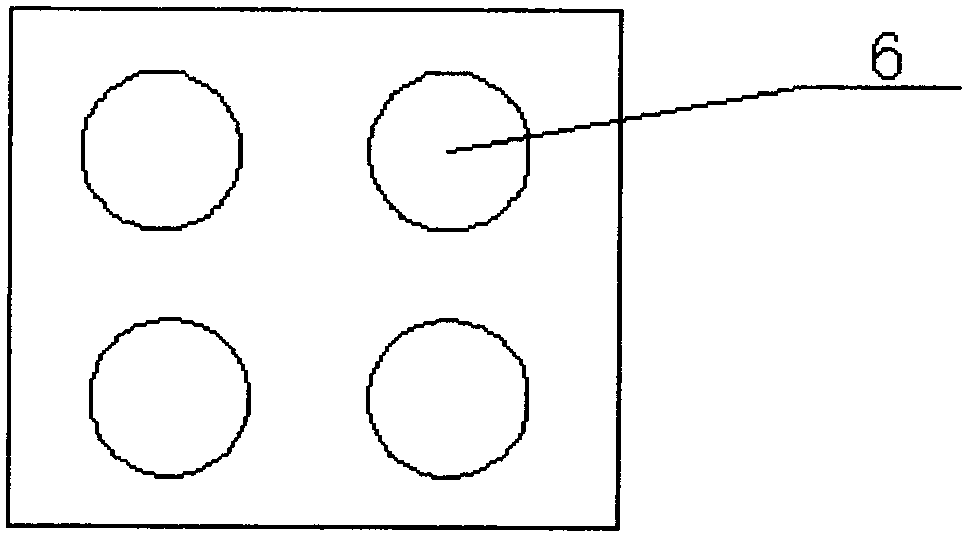

[0015] see figure 1 and figure 2 As shown, the technical solution adopted in this specific embodiment is: it includes a circuit board body 1; the circuit board body 1 is composed of a circuit layer 2, an insulating layer 3 and a heat conducting layer 4, and an insulating layer is provided at the bottom of the circuit layer 2 3. A thermal conduction layer 4 is provided on the lower part of the insulating layer 3; several heat sinks 5 are provided inside the insulating layer 3, and through holes 6 for placing electronic component pins are provided on the heat sink 5.

[0016] The two adjacent heat sinks 5 are set up and down alternately, which increases the heat dissipation area, makes the temperature in the insulating layer more uniform, and is beneficial to the overall heat dissipation.

[0017] The working principle of this specific embodiment: by adding a heat sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com