Laser scanning observation device and laser scanning method

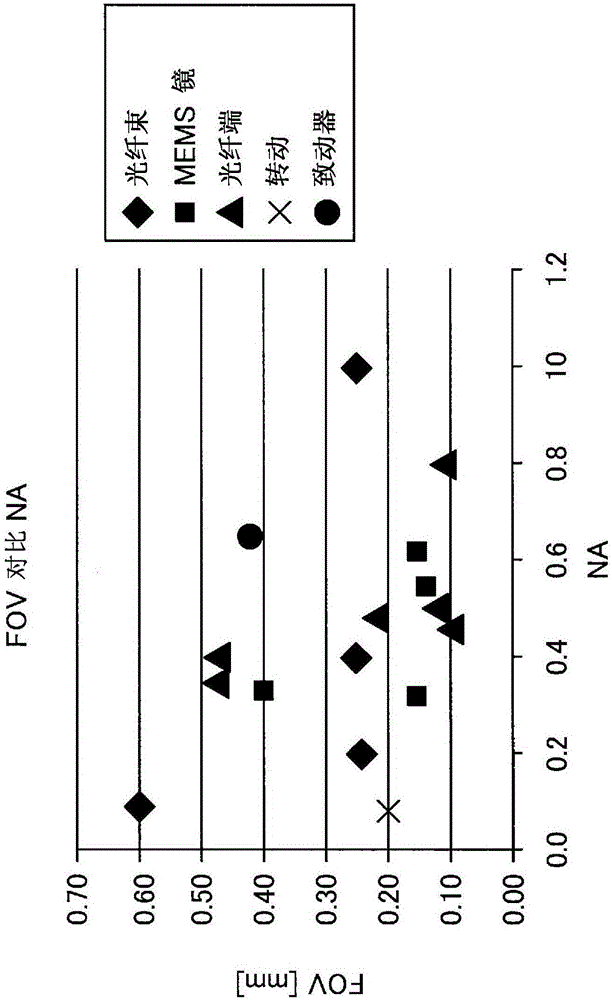

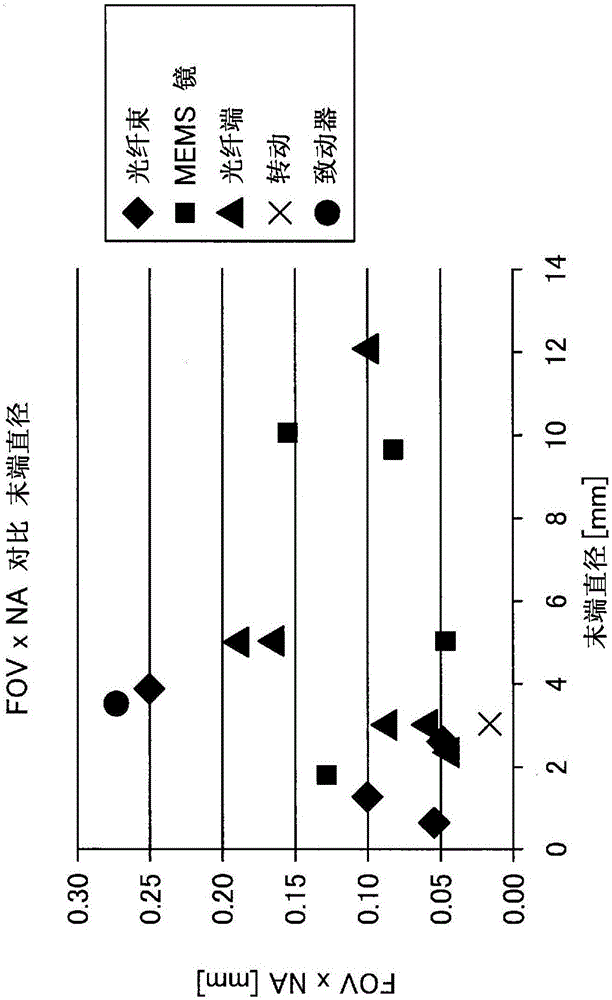

A laser scanning and observation device technology, applied in the field of laser scanning, can solve the problems of large size, high cost, and difficulty in installing optical systems, and achieve the effect of high-precision observation and wide field of view

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

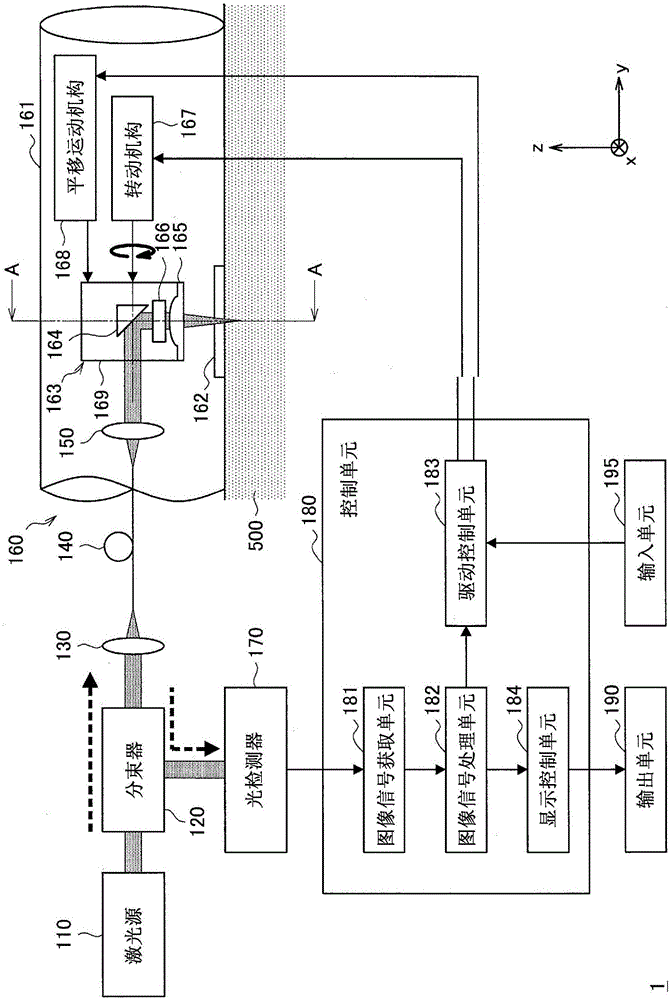

Method used

Image

Examples

no. 2 example

[0066] 4. Modify the instance

[0067] 4-1. Configuration in which the scanning unit includes a plurality of objective lenses

[0068] 4-1-1. Configuration in which the optical path changing element is a polarization beam splitter

[0069] 4-1-2. Structure in which the optical path changing element is a MEMS mirror

[0070] 4-1-3. Configuration in which the scanning unit includes an optical path branching element

[0071] 4-1-4. Configuration in which incident position of laser light relative to tube is fixed

[0072] 4-2. Other structures

[0073] 4-2-1. Configuration in which scanning unit has another rotation axis direction

[0074] 4-2-2. Modification of arrangement of objective lens in longitudinal direction of tube

[0075] 5. Construction of aberration correction unit

[0076] 5-1. Correction of astigmatism

[0077] 5-1-1. Cylindrical meniscus lens pair

[0078] 5-1-2. Cylindrical meniscus lens

[0079] 5-1-3. Cylindrical plano-concave lens

[0080] 6. Includi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com