Calcium supplementing preparation/granule and preparation method thereof

A technology for preparation and calcium supplementation, applied in pharmaceutical formulations, medical preparations containing active ingredients, peptide/protein ingredients, etc., can solve the problems of loss, poor absorption of ordinary calcium agents, poor solubility and absorption rate, etc. The effect of bone density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] This embodiment provides a calcium supplement preparation, including the following raw materials in parts by mass:

[0068] 20 parts of bone collagen, 6 parts of milk mineral salt, 0.8 part of casein phosphopeptide, 0.4 part of colostrum basic protein,

[0069] Vitamin D 3 0.0000067 parts, 4 parts of sweet orange powder, 26 parts of maltodextrin, 21 parts of skimmed milk powder.

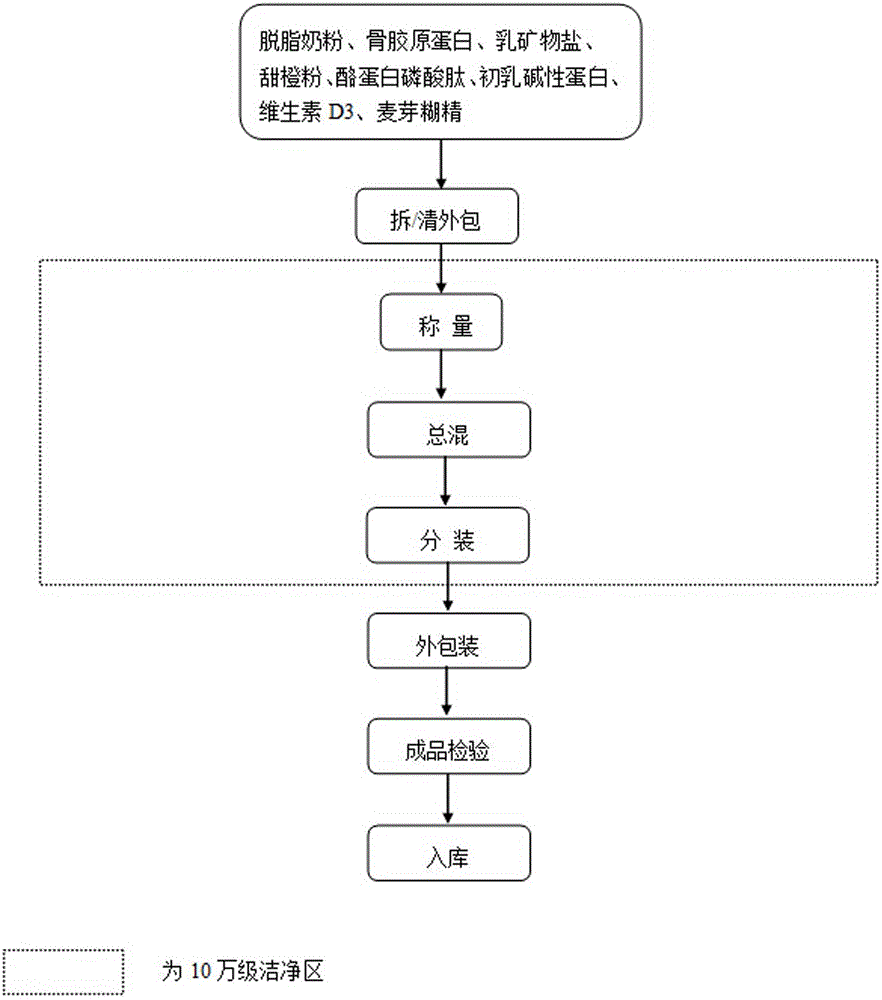

[0070] The above-mentioned calcium supplement preparations can also be in the form of granules, and the production process is as follows: figure 1 shown, including the following steps:

[0071] 1. Weighing:

[0072] In an environment with a temperature of 18°C and a relative humidity of 50%, weigh 20 parts of bone collagen, 6 parts of milk mineral salt, 0.8 part of casein phosphopeptide, 0.4 part of colostrum basic protein, and 0.0000067 part of vitamin D 3 , 26 parts of maltodextrin, 21 parts of skimmed milk powder, 4 parts of sweet orange powder.

[0073] 2. Total mix:

[0074] ①Mix ...

Embodiment 2

[0094] The difference between this embodiment and Example 1 is that it includes the following raw materials in parts by mass:

[0095] 30 parts of bone collagen, 10 parts of milk mineral salt, 1.2 parts of casein phosphopeptide, 0.6 part of colostrum basic protein,

[0096] Vitamin D 3 0.00001 parts, 6 parts of sweet orange powder, 40 parts of maltodextrin, 33 parts of skimmed milk powder.

[0097] The above-mentioned calcium supplement preparation can also be in the form of granules, and its production process includes the following steps:

[0098] 1. Weighing:

[0099] In an environment with a temperature of 26° C. and a relative humidity of 20%, the above raw materials were weighed in parts by mass.

[0100] 2. Total mix:

[0101] ①Mix vitamin D3 and 1 / 10 maltodextrin in equal increments, and record it as mixture A; mix casein phosphopeptide, colostrum basic protein, and sweet orange powder evenly, and record it as mixture B;

[0102] Note: Equal incremental mixing met...

Embodiment 3

[0125] The difference between this embodiment and Example 1 is that it includes the following raw materials in parts by mass:

[0126] 25 parts of bone collagen, 8 parts of milk mineral salt, 1.0 part of casein phosphopeptide, 0.5 part of colostrum basic protein,

[0127] Vitamin D 3 0.000007 parts, 5 parts of sweet orange powder, 30 parts of maltodextrin, 30 parts of skimmed milk powder.

[0128] The above-mentioned calcium supplement preparation can also adopt granules, and its production process includes the following steps:

[0129] 1. Weighing:

[0130] In an environment with a temperature of 20° C. and a relative humidity of 45%, the above-mentioned raw materials in parts by mass were weighed respectively.

[0131] 2. Total mix:

[0132] ①Mix vitamin D3 and 1 / 10 maltodextrin in equal increments, and record it as mixture A; mix casein phosphopeptide, colostrum basic protein, and sweet orange powder evenly, and record it as mixture B;

[0133] Note: Equal incremental ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com