Novel temperature and pressure variable adsorption technology

A temperature swing pressure swing adsorption and process technology, which is used in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of short adsorption cycle, large resource consumption, frequent impact of adsorption equipment, etc., and achieve good desorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

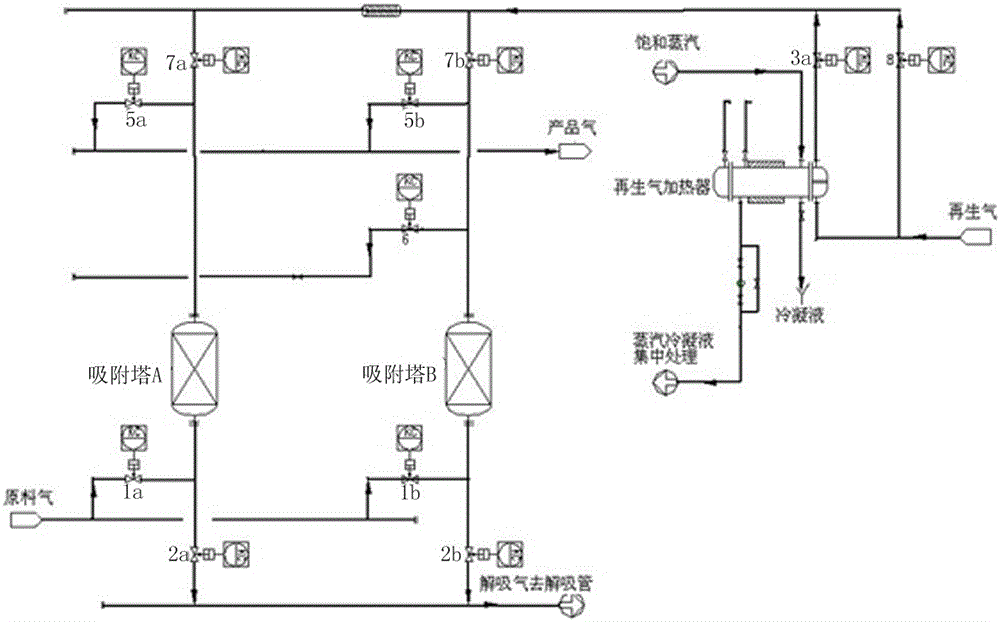

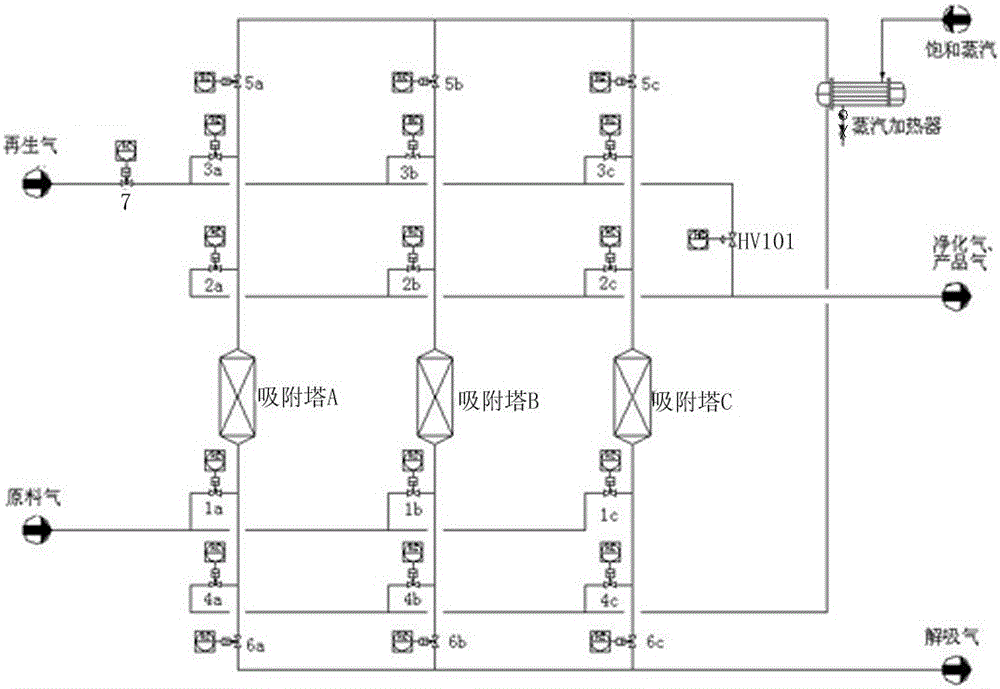

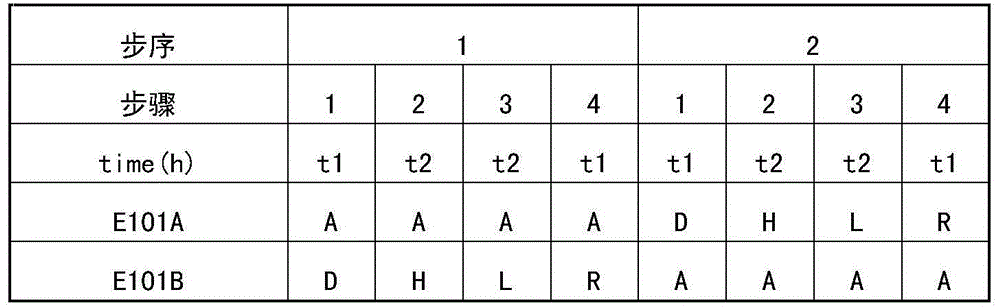

[0039] Such as figure 2 As shown, three adsorption towers are used in the new temperature swing pressure swing adsorption process. The towers are staggered in the arrangement of execution procedures to form a closed loop to ensure continuous input of raw materials and continuous output of products.

[0040] Taking tower A as an example, the description is as follows:

[0041] (1), Adsorption (A)

[0042] Open 1a, so that the raw material gas to be purified enters the adsorption tower A tower from bottom to top through the valve 1a, absorbs the impurity components under the working pressure, and the unadsorbed product components (i.e. product gas) flow out through the valve 2a. It is the product gas purified by the device, after the adsorption is completed, close the valve 1a and valve 2a, and stop feeding the raw material gas.

[0043] (2) Reverse step-down (D)

[0044] Since the pressure in the adsorption tower A is much higher than the ambient pressure or the pressure in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com