Double-silver low-emissivity coated glass capable of being subjected to high-temperature heat treatment and preparation method of double-silver low-emissivity coated glass

A low-emissivity coating and high-temperature heat treatment technology, applied in sputtering coating, chemical instruments and methods, glass/slag layered products, etc., can solve the problems of low transmittance, easy cracking and damage, etc., and achieve high transmittance , to avoid oxidation, to maintain the integrity of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

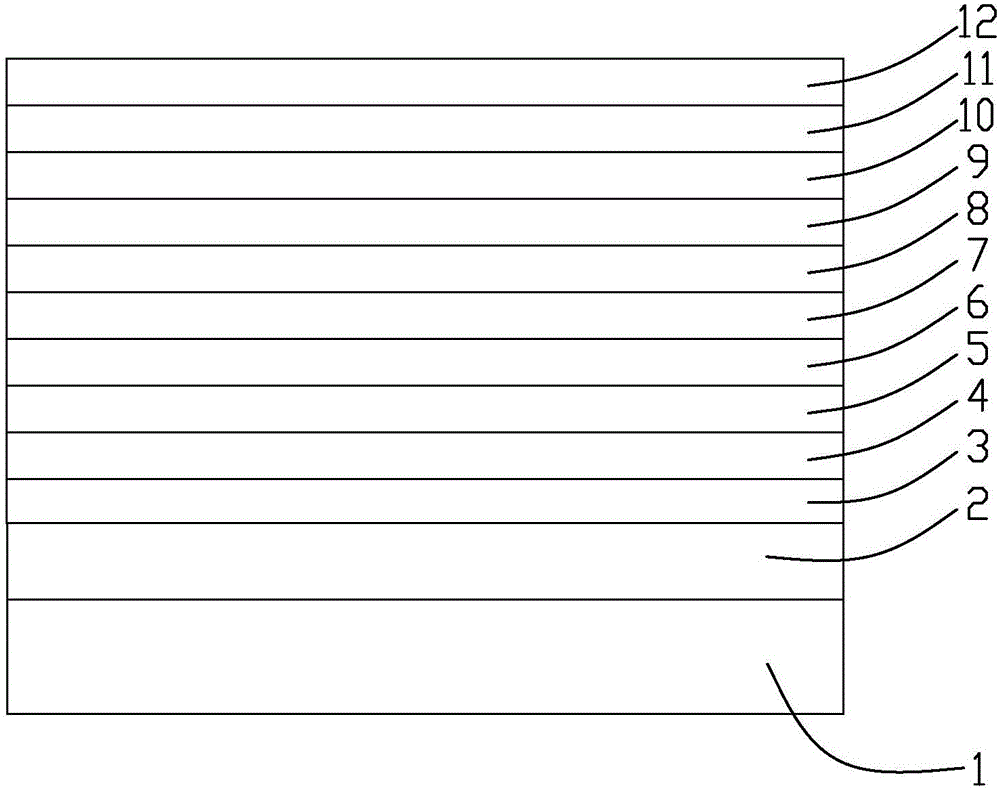

[0024] A kind of double-silver low-emissivity coated glass capable of high-temperature heat treatment, including a glass substrate 1, on the composite surface of the glass substrate 1, twenty film layers are sequentially and adjacently compounded from the inside to the outside, wherein The first film layer, the innermost layer, is SiO 2 Layer 2, the second film layer is Si 3 N 4 Layer 3, the third film layer is AZO layer 4, the fourth film layer is Ag layer 5, the fifth film layer is NiCrOx layer 6, and the sixth film layer is Si 3 N 4 Layer 7, the seventh film layer is AZO layer 8, the eighth film layer is Ag layer 9, the ninth film layer is NiCrOx layer 10, and the tenth film layer is Si 3 N 4 Layer 11, the eleventh film layer, that is, the outermost layer is the ZrNx layer 12.

[0025] The first film layer SiO 2 Layer 2 is an acidic oxide silicon dioxide layer, which is an adhesion-enhancing layer and a base film layer that prevents the diffusion of sodium ions in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com