A water reuse system and process for treating printing and dyeing wastewater by quality

A technology for the treatment of printing and dyeing wastewater and its quality, which is applied in the textile industry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

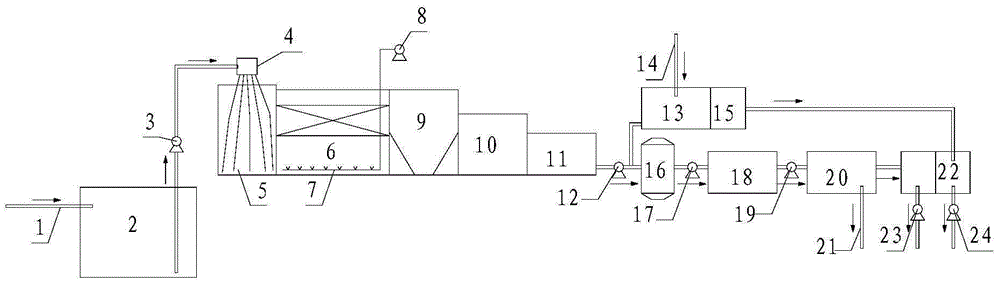

Method used

Image

Examples

Embodiment 1

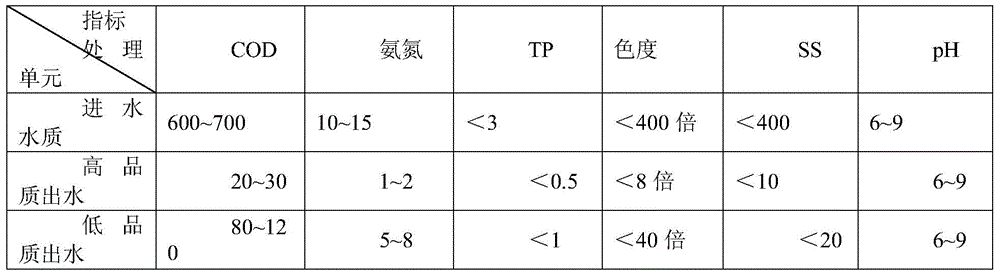

[0062] This process is applied to a sewage treatment station of a printing and dyeing enterprise. The design volume of sewage treatment is 2200t / d, of which 1100t / d is treated as high-quality reclaimed water, and the remaining 1100t / d is treated as low-quality reclaimed water. See Table 1 for the quality indicators of station influent water quality and reused water quality.

[0063] Table 1 Influent Water Quality and Reuse Water Quality Index Unit of Sewage Station: mg / L

[0064]

[0065] The water consumption of high-quality water after treatment is 605t / d, and the reuse rate is about 55%. About 95%, sensitive factors such as effluent water hardness meet the production requirements, mainly used in dark dyeing process and washing tanks, washing facilities, washing workshops and other processes. The total reclaimed water consumption of the sewage station is 1655t / d, and the total reuse rate is 75%. The emission reduction is obvious and the economic benefits are obvious. It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com