Process and device for preparing 1,6-hexanediol

A technology of hexanediol and process, applied in 1 field, can solve the problems such as the lack of large-scale production enterprises, and achieve the effects of saving costs, avoiding potential safety hazards, and avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

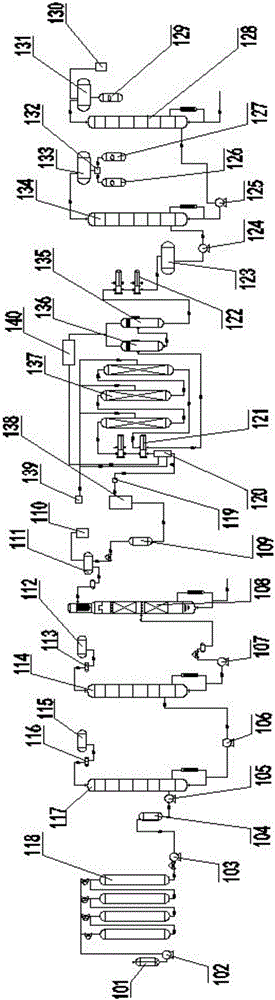

Image

Examples

Embodiment 1

[0047] This embodiment provides a kind of technique for preparing 1,6-hexanediol, comprising the following steps:

[0048] A. Esterification reaction: 1,6-adipic acid and methanol are prepared in a weight ratio of 1:1 and then added to the esterification reactor, and the esterification reaction occurs under the action of the esterification reaction catalyst and activated carbon; activated carbon The dosage is 0.05~0.2% of the total weight of raw materials, preferably 0.1%; the reaction temperature is 115~118°C, the reaction pressure is 0.3~0.5Mpa, and the reaction time is 8 hours. After the raw materials are completely reacted, adipic acid containing The reaction solution of dimethyl ester;

[0049] B. Alkalinity adjustment: the reaction solution containing dimethyl adipate obtained in step A is added in a neutralization reactor, and neutralized with an alkali solution to obtain a reaction solution with a pH value of 6.5 to 7;

[0050] C. Distillation: The reaction solution w...

Embodiment 2

[0057] Such as figure 1 As shown, a device for preparing 1,6-hexanediol is provided in this embodiment, so as to be applicable to the process for preparing 1,6-hexanediol in Example 1, which includes: esterification Reaction device and hydrogenation reaction device.

[0058] The esterification reaction device includes a mixing tank 101, a first feed pump 102, an esterification reactor 118, a neutralization pump 103, a neutralization reactor 104, a first methanol removal pump 105, and a methanol removal distillation tower 117 connected in sequence , dehydration pump 106, dehydration distillation tower 114, degreasing pump 107 and degreasing distillation tower 108; The top of demethanol distillation tower 117 is provided with the first condenser 116 that is connected with methanol collection tank 115, and the top of dehydration distillation tower 114 is provided with The second condenser 113 connected with the water collection tank 112, the third condenser 111 connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com