High oxygen barrier polyethylene/nylon 6 nanocomposite material and preparation method thereof

A technology of nano-composite materials and high-density polyethylene, applied in flat products, other household appliances, applications, etc., can solve the problems of poor universality, achieve low cost, simple and easy-to-operate process, and improve barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

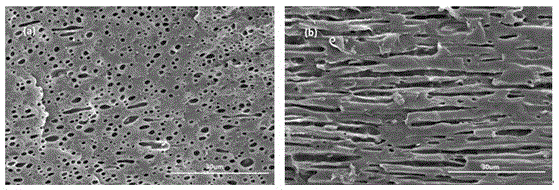

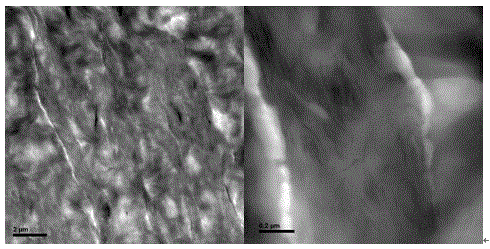

Image

Examples

Embodiment 1

[0021] Example 1 of the present invention: High oxygen barrier polyethylene nylon 6 nanocomposite material, calculated in parts by weight, including 70 parts of high-density polyethylene, 630 parts of nylon, 3 parts of bifunctional organically modified montmorillonite, compatible 1 part of agent and 0.005 part of antioxidant; the compatibilizer is ethylene-acrylic acid copolymer; the melt index of the high-density polyethylene is between 0.3-0.5.

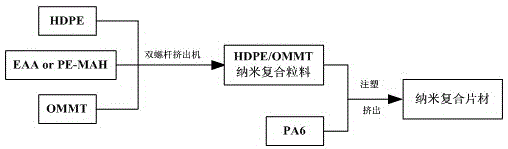

[0022] The preparation method of high-barrier polyethylene nylon 6 nanometer composite material comprises the steps:

[0023] 1) First, dry the bifunctional organic modified montmorillonite in an oven at 90°C for 12 hours, and dry the compatibilizer in an oven at 50°C for 2 hours; then dry the dried bifunctional organic The modified montmorillonite, high-density polyethylene and compatibilizer were melt-blended and granulated with a parallel twin-screw extruder according to the above mass fractions. The screw speed of the parallel t...

Embodiment 2

[0025] Example 2 of the present invention: high oxygen barrier polyethylene nylon 6 nanocomposite material, calculated in parts by weight, including 70 parts of high-density polyethylene, 630 parts of nylon, 3 parts of bifunctional organically modified montmorillonite, compatible 3 parts of agent and 0.005 part of antioxidant; the compatibilizer is ethylene-acrylic acid copolymer; the melt index of the high-density polyethylene is between 0.3-0.5.

[0026] The preparation method is the same as in Example 1.

Embodiment 3

[0027] Example 3 of the present invention: high oxygen barrier polyethylene nylon 6 nanocomposite material, calculated in parts by weight, including 70 parts of high-density polyethylene, 630 parts of nylon, and 3 parts of bifunctional organically modified montmorillonite, compatible 5 parts of agent and 0.005 part of antioxidant; the compatibilizer is ethylene-acrylic acid copolymer; the melt index of the high density polyethylene is between 0.3-0.5.

[0028] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com