Single-component glaze wall paint and preparation method thereof

A wall paint, one-component technology, applied to biocide-containing paints, coatings, antifouling/underwater coatings, etc., can solve problems such as high prices, lack of large-scale promotion, troublesome construction, etc., to achieve Meet the decoration requirements, excellent decoration effect, and improve construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

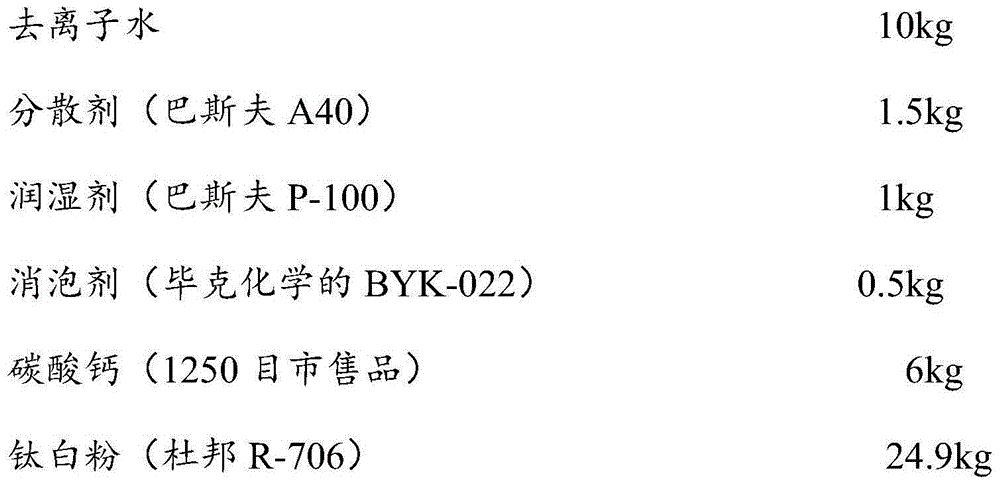

[0029] pulping stage

[0030]

[0031]

[0032] Put the raw materials into the dispersing kettle, stir and disperse at 1200rpm until the fineness of the slurry is less than 30um, and disperse normally for 60min, and add the materials while dispersing.

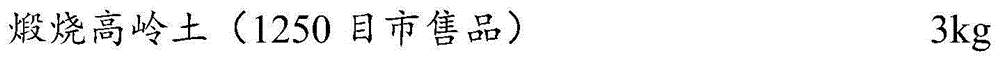

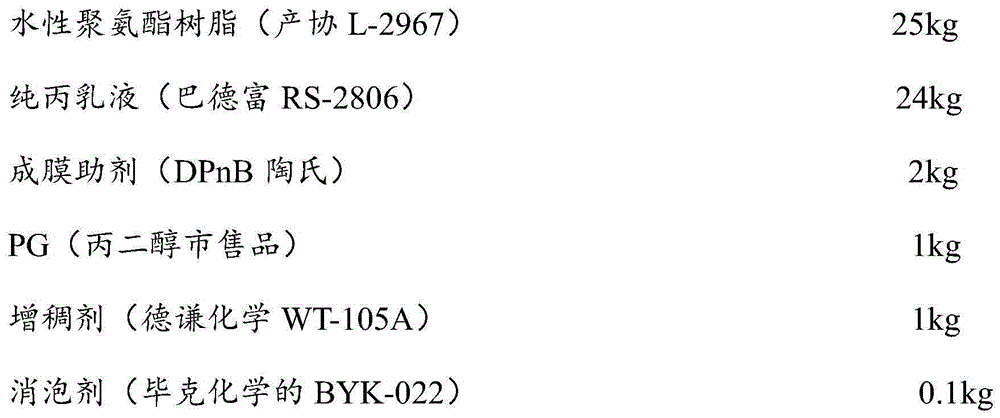

[0033] Letting stage

[0034]

[0035] Put the above-mentioned components in the let-down stage into the above-mentioned components in the pulping stage, reduce the stirring speed to 600rpm, stir and disperse for 60min, filter and pack to obtain 100kg of glazed wall paint.

[0036] Add about 10% water for the first time before painting, effectively disperse for more than 2 minutes, brush on the treated putty wall, wait for 4 to 6 hours to dry, then brush for the second time, and add about 5 % of water, after drying, a mercerized one-component glazed wall paint with good decorative effect, scrub resistance, mildew resistance and antibacterial effect can be obtained.

Embodiment 2

[0038] pulping stage

[0039]

[0040]

[0041] Put the raw materials into the dispersing kettle, stir and disperse at 1200rpm until the fineness of the slurry is less than 30um, and disperse normally for 60min, and add the materials while dispersing.

[0042] Letting stage

[0043]

[0044] Put the above-mentioned components in the let-down stage into the above-mentioned components in the pulping stage, reduce the stirring speed to 600rpm, stir and disperse for 60min, filter and pack to obtain 100kg of glazed wall paint.

[0045] Add about 10% water for the first time before painting, effectively disperse for more than 2 minutes, brush on the treated putty wall, wait for 4 to 6 hours to dry, then brush for the second time, and add about 5 % of water, after drying, a shell light one-component glazed wall paint with good decorative effect, scrub resistance, mildew resistance and antibacterial effect can be obtained.

Embodiment 3

[0047] pulping stage

[0048]

[0049]

[0050] Put the raw materials into the dispersing kettle, stir and disperse at 1200rpm until the fineness of the slurry is less than 30um, and disperse normally for 60min, and add the materials while dispersing.

[0051] Letting stage

[0052]

[0053] Put the above-mentioned components in the let-down stage into the above-mentioned components in the pulping stage, reduce the stirring speed to 600rpm, stir and disperse for 60min, filter and pack to obtain 100kg of glazed wall paint.

[0054] Add about 10% water for the first time before painting, effectively disperse for more than 2 minutes, brush on the treated putty wall, wait for 4 to 6 hours to dry, then brush for the second time, and add about 5 % of water, after drying, the matte single-component glazed wall paint with good decorative effect, scrub resistance, mildew resistance and antibacterial effect can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com