Built-in FRP locally restrained concrete combined member

A technology of restraint concrete and local restraint, applied in the direction of columns, piers, pillars, etc., can solve the problems of increasing the amount of FRP, limited restraint effect, reduced restraint effect, etc., to avoid steel corrosion, good durability, and high bearing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

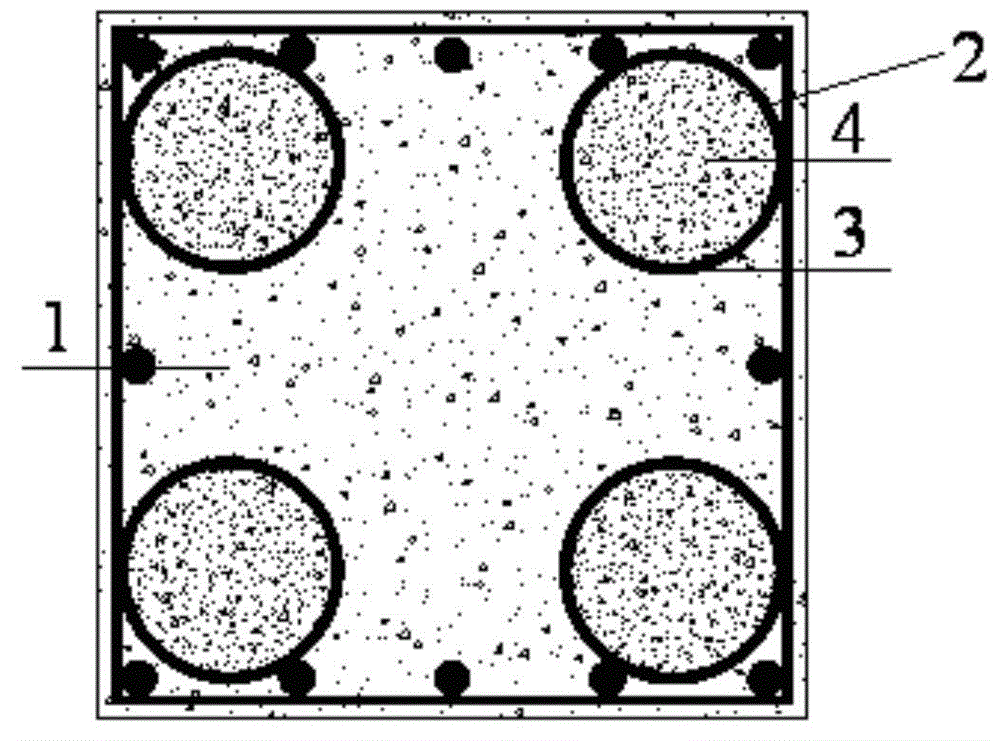

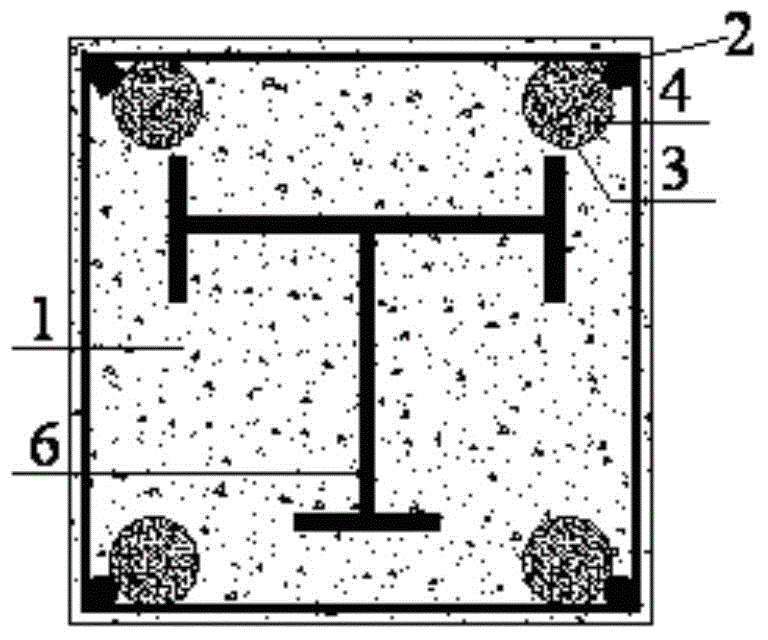

[0032] Such as Figure 8 Shown: A built-in FRP locally confined concrete composite column for high-rise structures, which is composed of an external concrete column 1 and an internal FRP-confined concrete sub-column 2. Among them, the external concrete column 1 is an ordinary concrete column, and the longitudinal reinforcement is 12C φ 20. The stirrup is φ12100, the concrete of the column body is C30, and the thickness of the protective layer is 30mm. The FRP confined concrete sub-column 2 is composed of an FRP pipe 3, an internal concrete 4 and an internal profile 6, and the FRP pipe 3 is a carbon fiber reinforced epoxy resin winding pipe with a circular cross section. Concrete 4 inside the FRP pipe adopts C60 high-strength concrete. The internal profile 6 is 20#A I-beam, and the FRP-confined concrete sub-column 2 is arranged inside the stirrup along the four corners of the composite column section. All concrete was poured in situ.

Embodiment 2

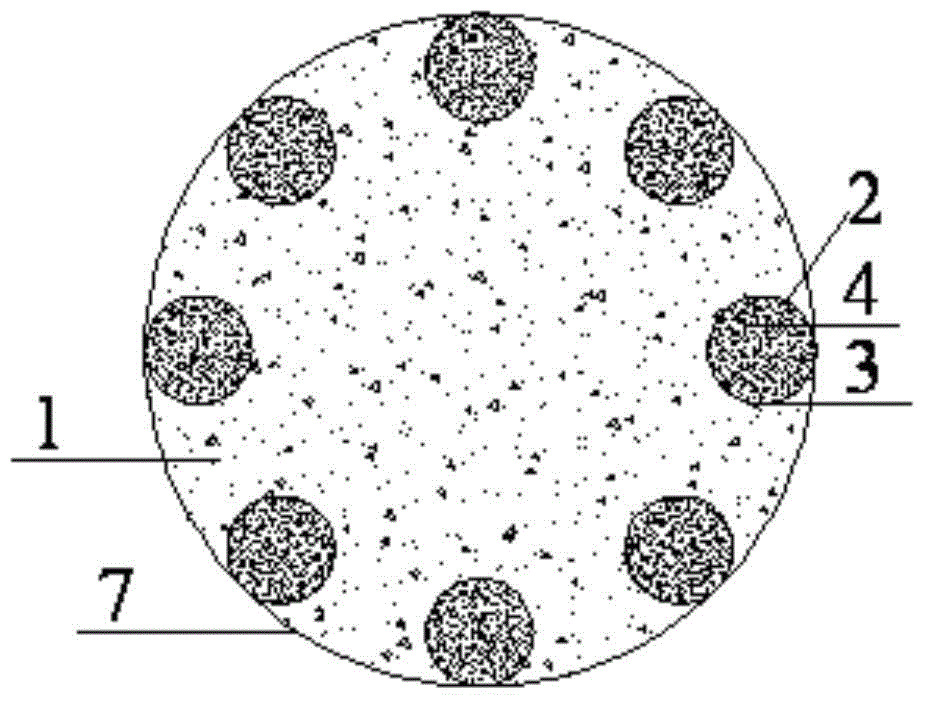

[0034] Such as Figure 9 Shown: a high-bearing-capacity pile in the form of a built-in FRP locally restrained concrete composite structure, consisting of an external concrete column 1 and an internal FRP-confined concrete sub-column 2. The external concrete column 1 is a steel pipe-concrete-steel pipe column with a circular cross-section, in which the longitudinal reinforcement is 8 φ 25. The stirrup is φ14150, the column concrete is C40, and the thickness of the protective layer is 50mm. The FRP confined concrete sub-column 2 is composed of FRP pipe material 3 and internal concrete 4, and the FRP pipe 3 is a glass fiber reinforced unsaturated polyester resin winding pipe with a circular cross section. The FRP-confined concrete sub-column 2 is arranged on the inner side of the stirrup 9 along the circumferential direction of the longitudinal reinforcement of the composite column section. The combined component is integrally prefabricated in the factory. In order to prevent...

Embodiment 3

[0036] Such as Figure 10 Shown: A built-in FRP locally confined concrete composite structure for large bridge piers, consisting of external concrete-like columns 1 and internal FRP-confined concrete sub-columns 2. The external concrete column 1 is an ordinary reinforced concrete column, its section is a composite section composed of a rectangle and two semicircles, and the interior is a rectangular hollow area, the column body is made of concrete C30, and the thickness of the protective layer is 30mm. The FRP confined concrete sub-column 2 is composed of an FRP pipe 3 and internal concrete 4, and the FRP pipe 3 is a glass fiber reinforced epoxy resin winding pipe with a circular cross section. The concrete 4 inside the FRP pipe 3 adopts C80 high-strength concrete. The FRP-confined concrete sub-column 2 is arranged along the inner side of the stirrup 9 of the semi-circular section of the composite column. All concrete was poured in situ.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com