A springless quick response valve

A fast-response, spring-free technology, applied in valve details, valve device, valve operation/release device, etc., can solve the problems of limiting the performance of the air compressor distribution system, low reliability, complex structure, etc., to achieve compact structure, The effect of increasing the cooling efficiency of oil heat exchange and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

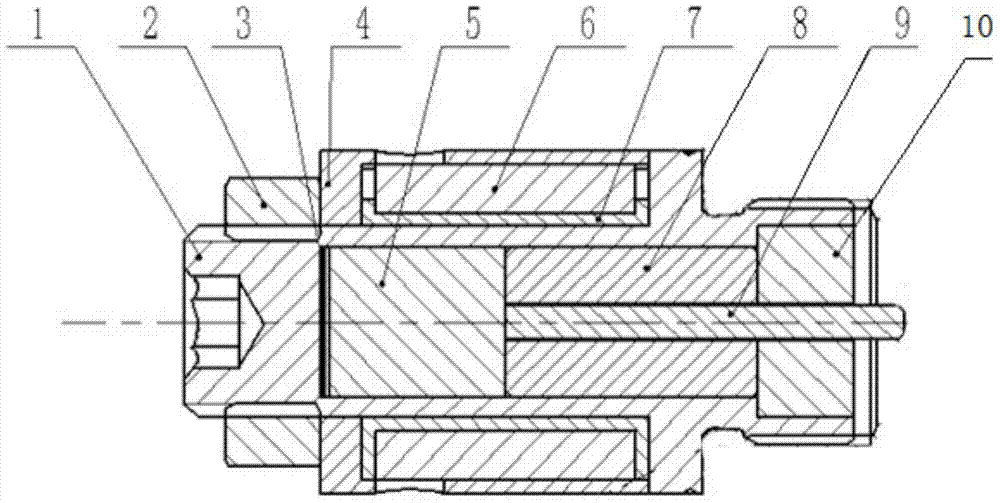

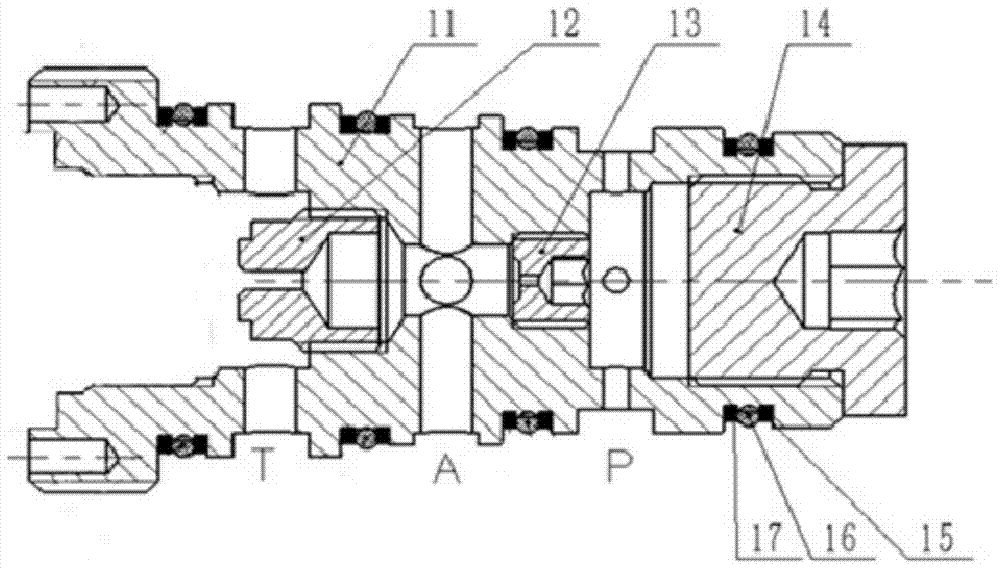

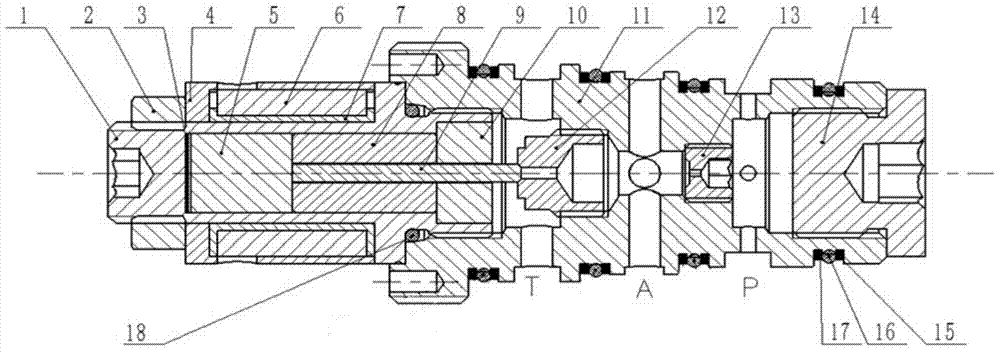

[0017] Such as Figure 1-3 As shown, a springless quick-response valve includes an electromagnet shell 1, a hexagonal thin nut 2, a magnetic isolation copper sheet 3, an electromagnet sleeve 4, an armature 5, a battery iron coil 6, a skeleton 7, and an electromagnet core 8 , push rod 9, electromagnet retaining ring 10, valve seat 11, large liquid resistance 12, small liquid resistance 13 and plug 14. Such as figure 2 As shown, the two ends of the valve seat 11 are opened, which are respectively the first opening and the second opening. Along the direction from the second opening to the first opening, the valve seat 11 is provided with a first radial through hole and a second radial through hole in sequence. The openings of the first radial through hole, the second radial through hole and the third radial through hole are P port, A port and T port respectively; the first opening is used for mounting Enter the large liquid resistance 12 and be connected with the electromagnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com