Method for calibrating surface-mounted fiber grating strain sensor

A technology of strain sensor and optical fiber grating, which is applied in the direction of instruments, optical devices, measuring devices, etc., can solve the problem that the influence of the strain sensitivity of the strain optical fiber grating strain sensor is not considered, and the measured value of the optical fiber grating deviates from the true strain value of the object under test , deviation of actual strain measurement results and other issues, to achieve the effect of accuracy guarantee, temperature stability, and small temperature fluctuation interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings, so as to better understand the present invention.

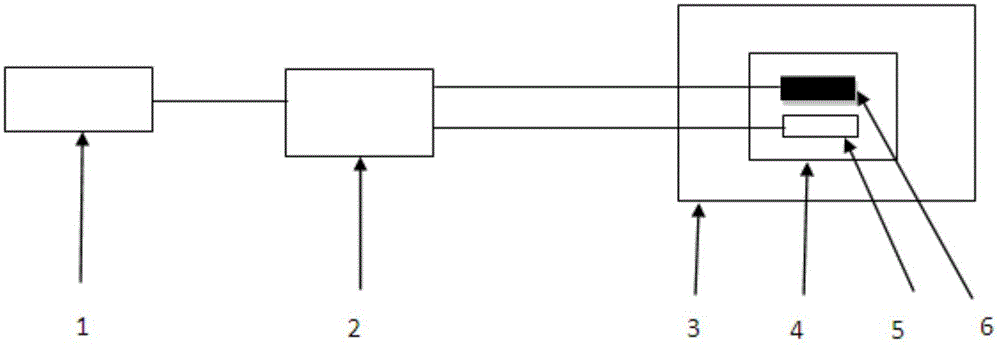

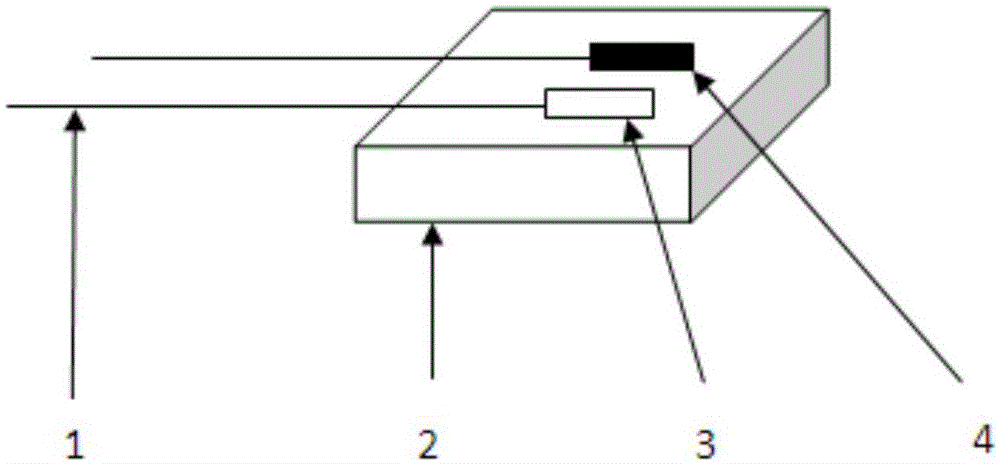

[0023] The calibration method of the surface-mounted optical fiber grating strain sensor of the present invention utilizes the finite element analysis of the strain generated by thermal expansion and contraction of materials to realize the calibration of the sensitivity coefficient of the optical fiber grating strain sensor. Such as figure 1 As shown, the calibration system of the fiber grating strain sensor calibration method of the present invention includes a computer 1, a fiber grating demodulator 2, a constant temperature bath 3, a standard part 4, a fiber grating temperature sensor 5, and a fiber grating strain sensor 6. Such as figure 2 As shown, the FBG strain sensor is pasted on the standard part along the horizontal direction, and the FBG temperature sensor is arranged near the FBG strain sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com