Method for making internal control standard sample

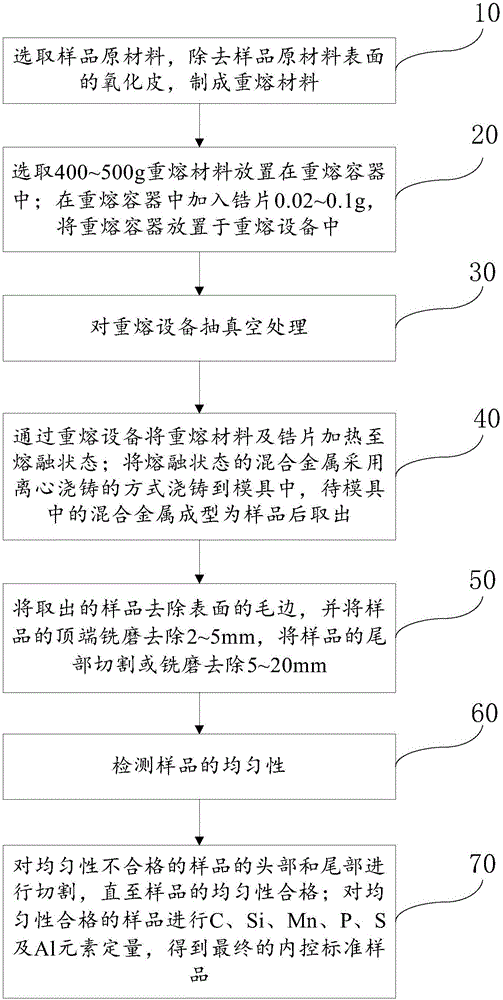

A production method and standard sample technology, applied in the field of metallurgy, can solve the problems of unfavorable pre-furnace composition precise control, ineffective guidance, poor sample uniformity, etc., and achieve the effects of saving manpower and material resources, convenient material collection, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

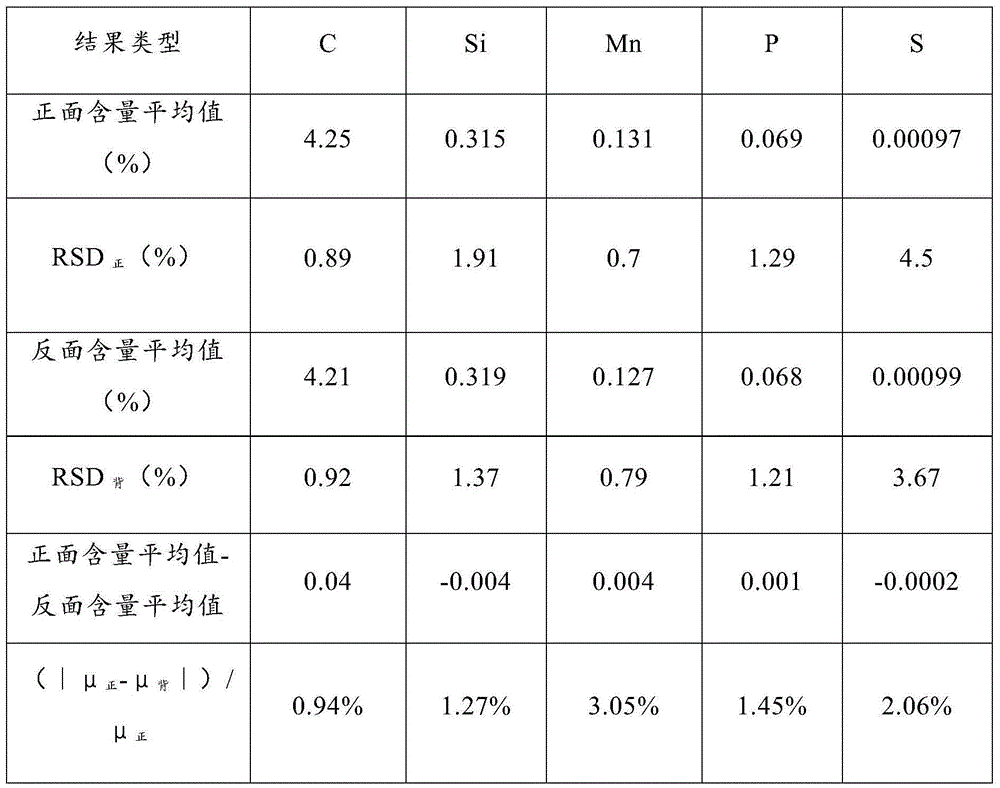

Examples

Embodiment 1

[0056] Select seven small cylindrical cast iron samples with similar composition after desulfurization in front of the furnace as the sample raw material, remove the oxide skin on the surface of the sample raw material, and make it into a remelted material.

[0057] Select 458g of remelting material and place it in the remelting container, add 0.02g of zirconium pieces into the remelting container, and place the remelting container in the remelting equipment.

[0058] Vacuumize the remelting equipment. Specifically include: first step, connect the inner cavity of the remelting equipment with high-purity argon gas; the purity of the argon gas is 99.9996%, and the pressure of the argon gas is controlled at 0.1 MPa. The second step is to connect the inner cavity of the remelting equipment to the vacuum pump, and use the vacuum pump to vacuum the inside of the remelting equipment twice, and stop when the vacuum degree of the inner cavity of the remelting equipment is greater than ...

Embodiment 2

[0066] Select five racquet-shaped steel samples produced in front of the furnace with similar components as the sample raw materials, remove the oxide skin on the surface of the sample raw materials, and make remelted materials.

[0067] Select 435g of remelting material and place it in the remelting container, add 0.1g of zirconium sheet into the remelting container, and place the remelting container in the remelting equipment.

[0068] Vacuumize the remelting equipment. Specifically include: first step, connect the inner cavity of the remelting equipment with high-purity argon gas; the purity of the argon gas is 99.9996%, and the pressure of the argon gas is controlled at 0.1 MPa. The second step is to connect the inner cavity of the remelting equipment to the vacuum pump, and use the vacuum pump to vacuum the inside of the remelting equipment for 4 times, and stop when the vacuum degree of the inner cavity of the remelting equipment is greater than or equal to -850mbar.

...

PUM

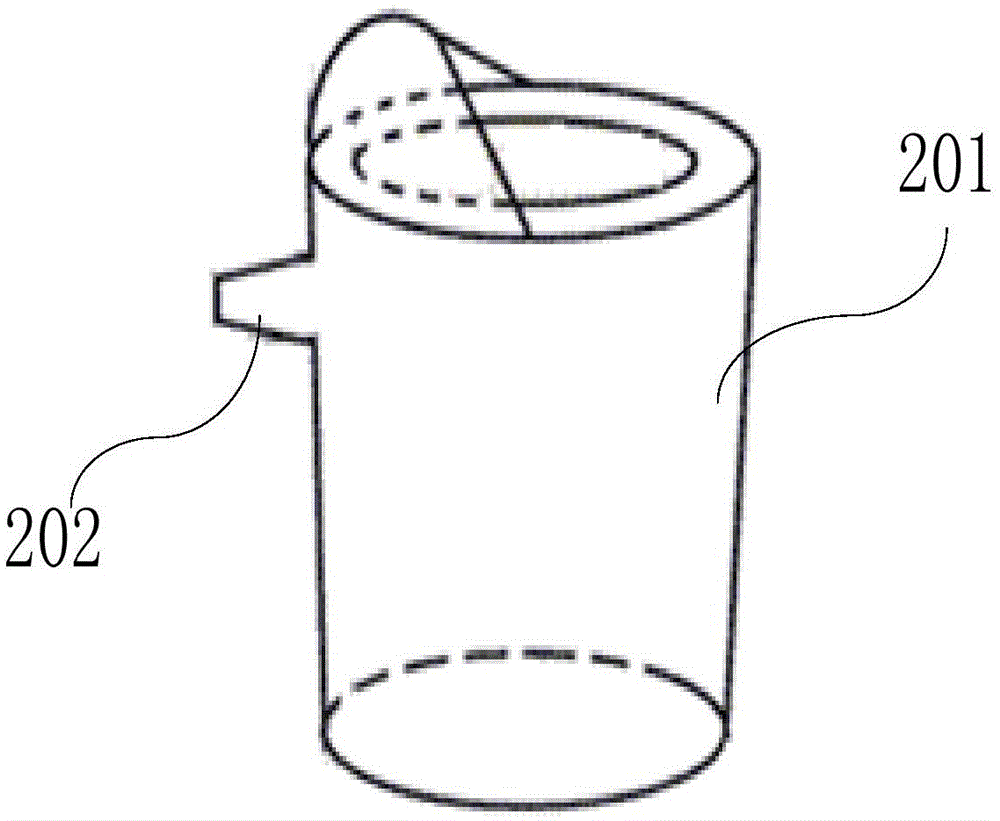

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com