Lithium sulfur battery positive electrode material

A positive electrode material, lithium-sulfur battery technology, applied in the direction of battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems of unfavorable battery high rate performance, unfavorable battery cycle application, and very large volume change, so as to improve the cycle Stability, prevention of other side effects, effects of avoiding direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

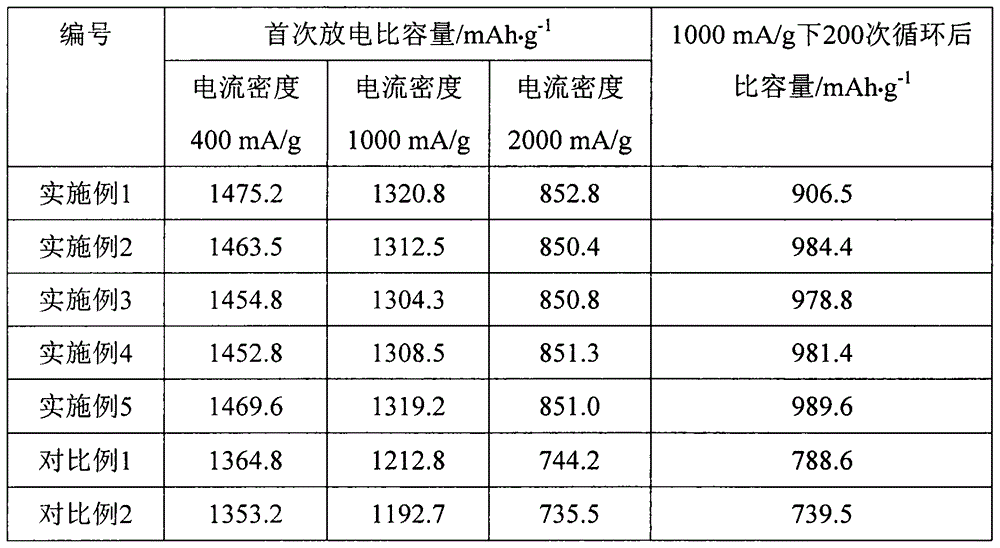

Examples

Embodiment 1

[0023] A lithium-sulfur battery positive electrode material, the material includes sulfur / graphene oxide / CNTs composite, the sulfur / graphene oxide / CNTs composite is coated with a conductive polymer layer, and the conductive polymer layer is coated with There is an adhesive layer.

[0024] The mass ratio of sulfur to graphene oxide in the sulfur / graphene oxide / CNTs composite is 4:1, and the mass ratio of sulfur to CNTs is 4:1; the conductive polymer material of the conductive polymer layer is polydopamine , the mass ratio of sulfur and polydopamine in the positive electrode material is 2:1; the binder of the binder layer is polyacrylic acid, and the mass ratio of sulfur and binder in the positive electrode material is 4:1.

Embodiment 2

[0026] A lithium-sulfur battery positive electrode material, the material includes sulfur / graphene oxide / CNTs composite, the sulfur / graphene oxide / CNTs composite is coated with a conductive polymer layer, and the conductive polymer layer is coated with There is an adhesive layer.

[0027] The mass ratio of sulfur to graphene oxide in the sulfur / graphene oxide / CNTs composite is 5:2, and the mass ratio of sulfur to CNTs is 4:1; the conductive polymer material of the conductive polymer layer is polydopamine , the mass ratio of sulfur and polydopamine in the positive electrode material is 2:1; the binder of the binder layer is polyacrylic acid, and the mass ratio of sulfur and binder in the positive electrode material is 4:1.

Embodiment 3

[0029] A lithium-sulfur battery positive electrode material, the material includes sulfur / graphene oxide / CNTs composite, the sulfur / graphene oxide / CNTs composite is coated with a conductive polymer layer, and the conductive polymer layer is coated with There is an adhesive layer.

[0030] The mass ratio of sulfur to graphene oxide in the sulfur / graphene oxide / CNTs composite is 3:1, and the mass ratio of sulfur to CNTs is 3:1; the conductive polymer material of the conductive polymer layer is polydopamine , the mass ratio of sulfur and polydopamine in the positive electrode material is 2:1; the binder of the binder layer is polyacrylic acid, and the mass ratio of sulfur and binder in the positive electrode material is 4:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com