Multi-stage submerged membrane separation device and membrane separation method

一种膜分离、浸渍型的技术,应用在半透膜分离、化学仪器和方法、膜等方向,能够解决膜面积限制等问题,达到减少频率、高过滤通量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

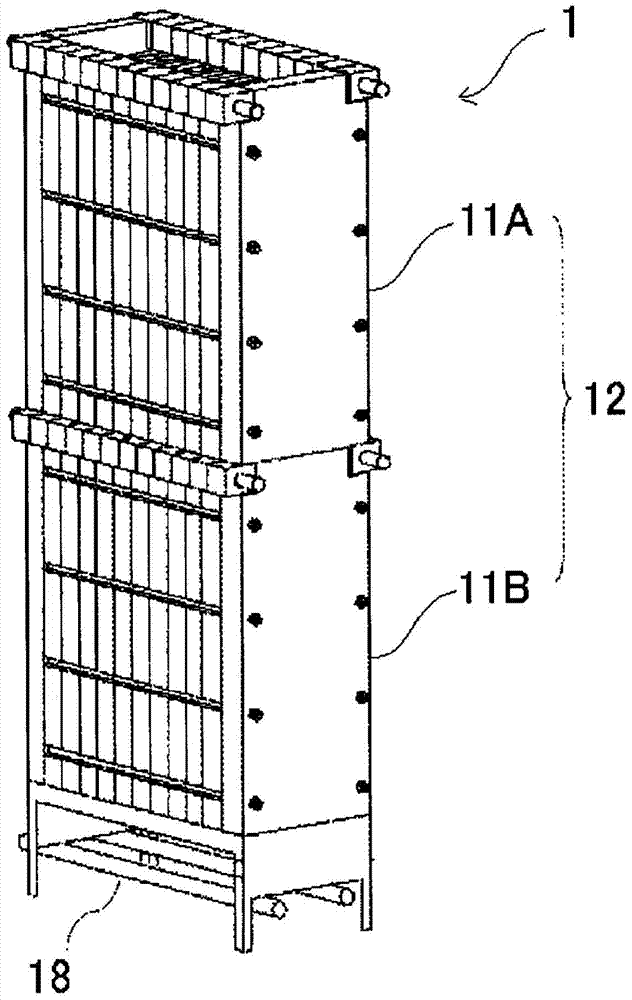

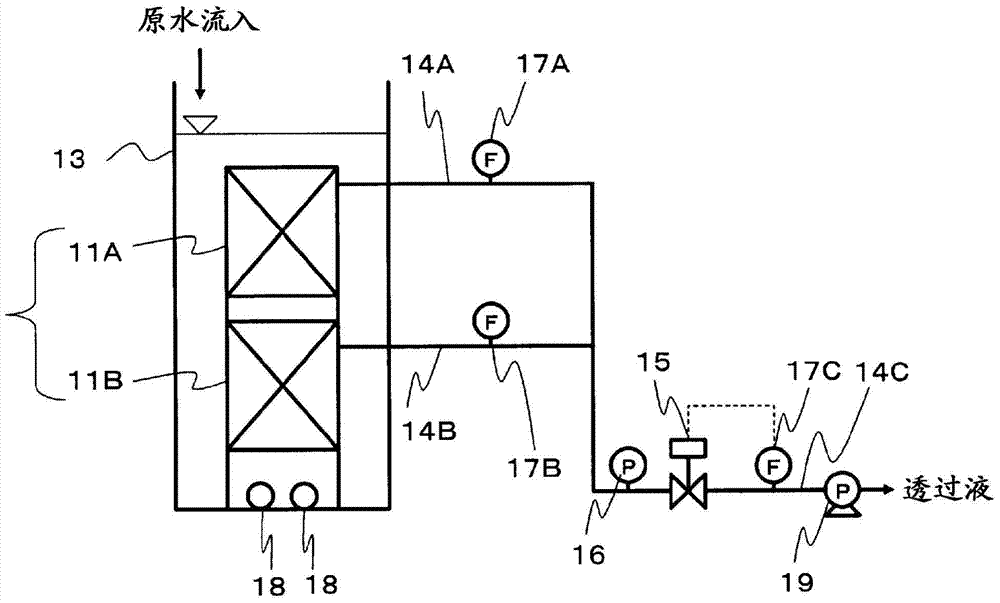

[0127] In Example 1, by configuring figure 2 The setup shown uses membrane module 1 for experiments. The experiment was performed under controlled filtration flow of the membrane modules. A flow meter is provided for each of the upper and lower membrane units, and a pressure gauge, a flow control valve, a flow meter, and a filter pump are installed on the permeate piping installed after the permeate piping from the upper and lower membrane units is combined. Operation is first through the filter pump, then switched to flow control valve, and then the filter pump is stopped. Here, the filtration operation is performed by a filtration pump and a flow control valve, combined with a flow meter to keep the flow constant. Filtration flow is 168m 3 / d, repeat the filtration cycle with 9 minutes of filtration and 1 minute off. The filtration pressure difference was calculated by subtracting the filtration pressure 50 seconds after the end of the filtration from the filtration ope...

Embodiment 2

[0131] Experiments were performed in the same manner as in Example 1 except that membrane module 2 was used. The experimental results showed that, if Figure 6 As shown, the filtration pressure differences in the upper and lower membrane units were all lower than the upper filtration pressure difference upper limit (25 kPa) allowing stable filtration operation, and were considered to be temporarily stable even at high filtration fluxes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com