Absorbable medical suture with good compatibility and preparation method thereof

A suture and compatibility technology, applied in the field of medical sutures, can solve the problems of slow degradation rate, supply, easy cell adhesion, etc., and achieve the effect of increasing smoothness, reducing pain, and reducing tissue drag.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

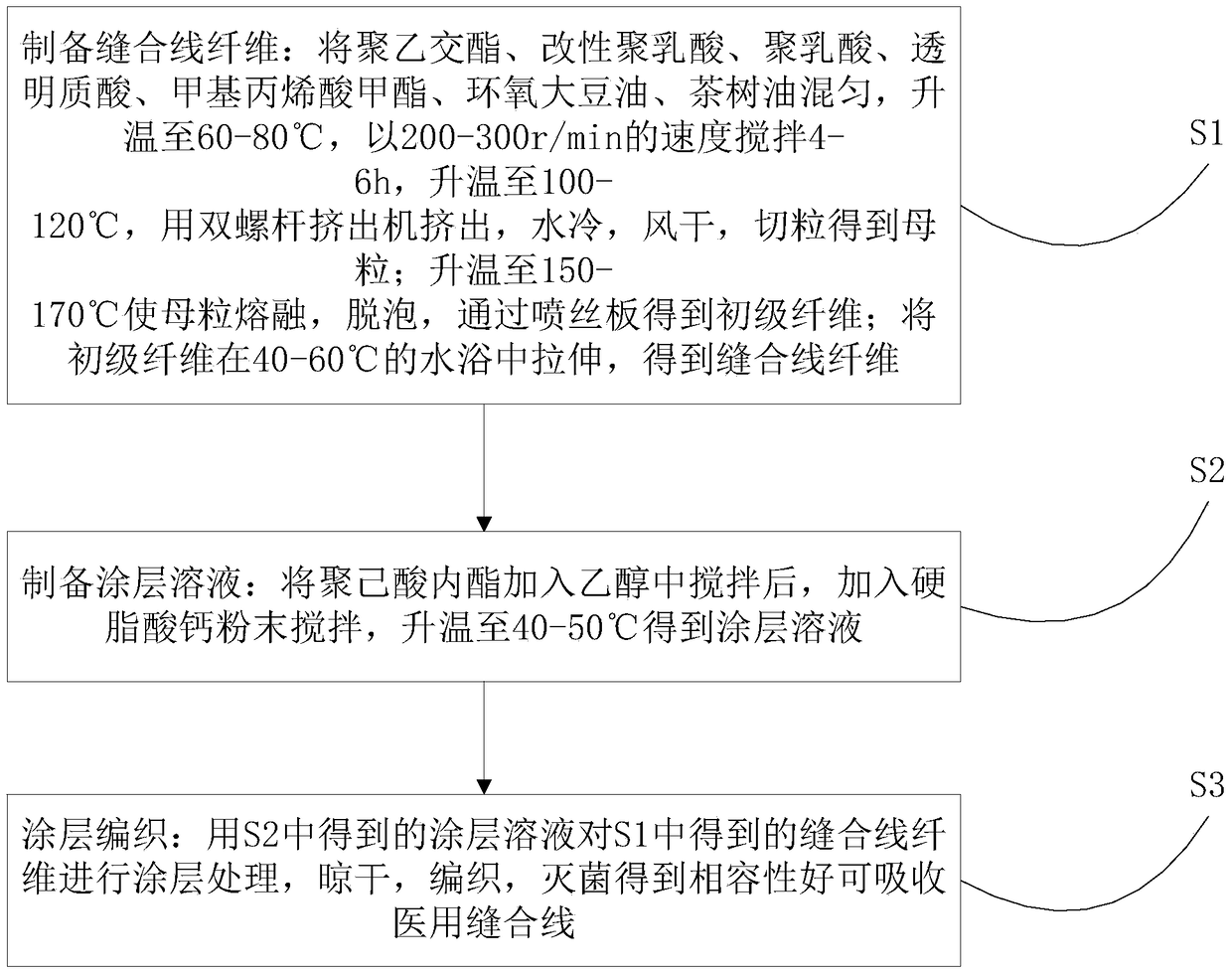

[0031] refer to figure 1 , the preparation method of a kind of good compatibility absorbable medical suture that the present invention proposes, comprises the steps:

[0032] S1. Preparation of suture fiber: mix polyglycolide, modified polylactic acid, polylactic acid, hyaluronic acid, methyl methacrylate, epoxy soybean oil, and tea tree oil, heat up to 60-80°C, and heat up to 60-80°C. Stir at a speed of -300r / min for 4-6 hours, heat up to 100-120°C, extrude with a twin-screw extruder, water-cool, air-dry, and pelletize to obtain masterbatches; heat up to 150-170°C to melt the masterbatch and defoam , obtain primary fibers through a spinneret; stretch the primary fibers in a water bath at 40-60°C to obtain suture fibers;

[0033] S2. Prepare a coating solution: add polycaprolactone into ethanol and stir, then add calcium stearate powder and stir, and heat up to 40-50°C to obtain a coating solution;

[0034] S3. Coating weaving: Coating the suture fibers obtained in S1 with t...

Embodiment 1

[0037] A kind of absorbable medical suture with good compatibility, its raw material comprises by weight: 40 parts of polyglycolide, 10 parts of modified polylactic acid, 70 parts of polylactic acid, 10 parts of hyaluronic acid, 7 parts of methyl methacrylate 4 parts, 4 parts of epoxy soybean oil, 4 parts of tea tree oil, 1 part of polycaprolactone, 0.3 part of calcium stearate, 15 parts of ethanol;

[0038]Wherein, the preparation method of the modified polylactic acid is as follows: add 2 parts of polylactic acid in 20 parts of chloroform to dissolve in parts by weight, feed nitrogen, add 6 parts of 2-ethylhexyl methacrylic anhydride, heat up to 70 ° C, Insulate for 2 hours, cool, add dropwise to 150 parts of ethanol, filter with suction, heat up to 40°C, and dry in vacuum for 15 hours to obtain the intermediate material; add 7 parts of itaconic acid to 40 parts of oxalyl chloride in parts by weight, heat up to 90°C, and keep warm 3h, suction filtration, soak the filter cake...

Embodiment 2

[0044] A kind of absorbable medical suture with good compatibility, its raw material comprises by weight: 20 parts of polyglycolide, 20 parts of modified polylactic acid, 50 parts of polylactic acid, 20 parts of hyaluronic acid, 5 parts of methyl methacrylate 6 parts, 6 parts of epoxy soybean oil, 2 parts of tea tree oil, 5 parts of polycaprolactone, 0.1 part of calcium stearate, 30 parts of ethanol;

[0045] Wherein, the preparation method of the modified polylactic acid is as follows: add 4 parts of polylactic acid to 10 parts of chloroform to dissolve in parts by weight, feed nitrogen, add 13 parts of 2-ethylhexyl methacrylic anhydride, heat up to 50 ° C, Insulate for 4 hours, cool, add dropwise to 100 parts of ethanol, filter with suction, heat up to 60°C, and vacuum-dry for 10 hours to obtain the intermediate material; add 11 parts of itaconic acid to 30 parts of oxalyl chloride in parts by weight, heat up to 110°C, and keep warm 2h, suction filtration, soak the filter ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com