Machining method for precise taper holes of high-strength steel

A taper hole processing method and high-strength steel technology, which are applied in the field of machining, can solve the problems of the hole being in a flared state without improvement, difficult precision requirements, and easy to break.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

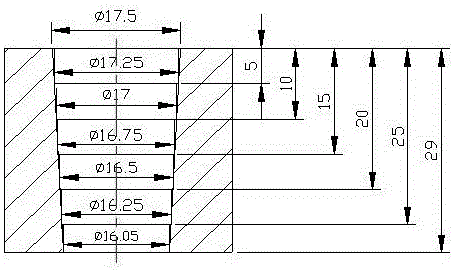

[0015] figure 2 The processing example in the above comes from the processing of the tapered hole of the rotating shaft of a certain model, and the material is 30GrMnSiNi2A , After heat treatment σb=1665±100MPa, taper hole φ17.5H9 taper 1:20K7, after many tests, according to figure 2 In the method shown, a group of straight holes is processed first, and then cylindrical holes φ16.05H29, φ16.25H25, φ16.5H20, φ16.75H15, φ17H10, φ17.25H5 are sequentially processed with a cemented carbide reamer. After processing, multiple The cylindrical hole constitutes a tapered hole, which successfully solves the processing bottleneck and provides a good reference for similar processing in the future.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com