Lead feeding system for lead-acid storage battery and control method of lead feeding system

A lead-acid battery and control method technology, applied in the stacking of objects, destacking, transportation and packaging of objects, etc., can solve the problems of low efficiency and poor stability of lead ingots, achieve stable and reliable operation, reduce errors, guarantee The effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

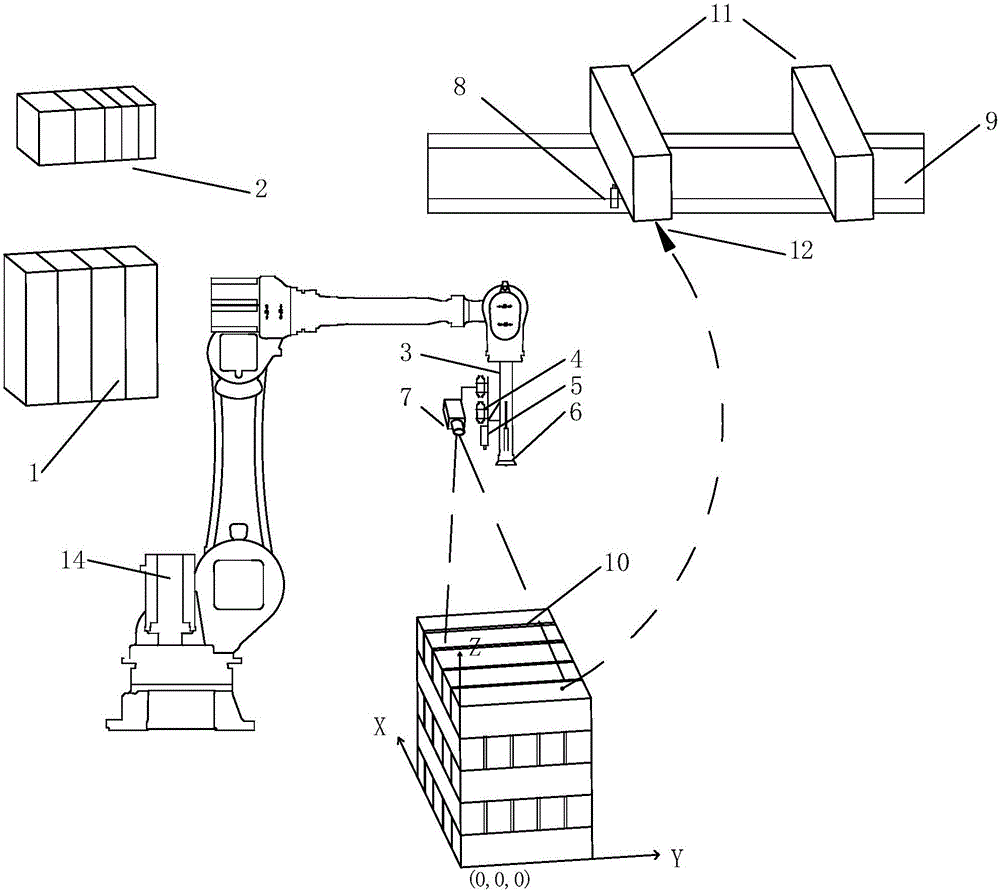

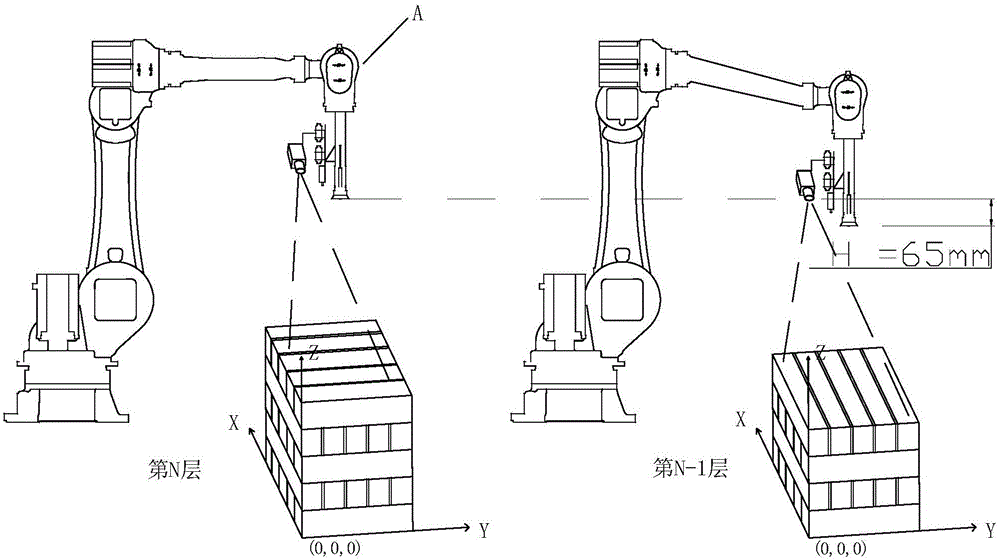

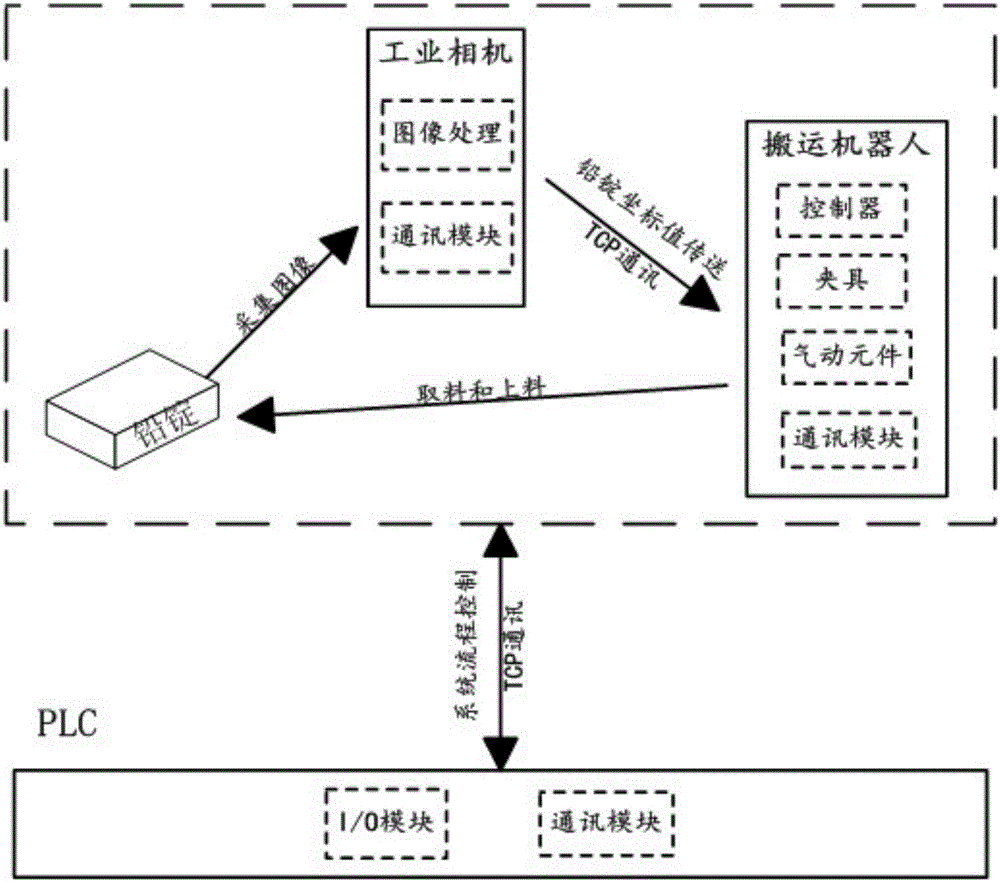

[0054] like Figure 1 to Figure 5 As shown, a lead loading system for a lead-acid battery includes a controller 1, a handling robot 14, a PLC 2, a fixture 3, a vacuum pressure switch 4, a feeding stroke switch 5, a pneumatic component 6, an industrial camera 7, and a feeding stroke switch 8 and the conveyor chain 9, the gripper 3 is installed at the end of the transport robot 14, the vacuum pressure switch 4, the retrieving stroke switch 5, the pneumatic element 6, and the industrial camera 7 are installed on the gripper 3, and the feeding stroke switch 8 is installed on the conveyor chain 9, the data of the PLC2, industrial camera 7, and controller 1 are exchanged and shared by TCP communication, and the loading position 12 of the conveyor chain 9 is located within the working range of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com