Method for extracting Anoectochilus roxburghii polysaccharides

An extraction method and polysaccharide extraction technology are applied in the field of extraction of clematis polysaccharide, which can solve the problems of low polysaccharide extraction rate and the like, and achieve the effects of high polysaccharide yield, mild conditions and stable process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

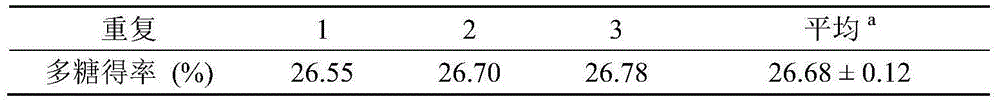

Examples

Embodiment 1

[0041] (1) Take the whole clematis herb, wash it, drain the water in a cool and ventilated place, dry it at 50°C, and pass it through a 40-mesh sieve to obtain clematis powder.

[0042] (2) Accurately weigh a certain amount of clematis whole herb powder 50.00g, soak in 10 times the volume (v:w) of 95% ethanol for 12 hours, filter, repeat the treatment twice, combine the two filtrates to concentrate for later use; place the filter residue in a cool place Ethanol was evaporated in a ventilated place, and then dried in an oven at 50°C to obtain a clematis pretreatment powder.

[0043] (3) Accurately weigh 15.00 g of Clematis clematis pretreated powder, add distilled water at a liquid-to-solid ratio of 1:30 (g:mL), bathe in water at 70°C for 90 minutes, filter with suction, and extract repeatedly 4 times. Combine 4 filtrate polysaccharide extracts.

[0044](4) The polysaccharide extract is fixed to volume, and the total sugar and reducing sugar content in the extract are determin...

Embodiment 2

[0046] (1) Take the whole clematis herb, wash it, drain the water in a cool and ventilated place, dry it at 50°C, and pass it through a 40-mesh sieve to obtain clematis powder.

[0047] (2) Accurately weigh a certain amount of clematis whole herb powder 50.00g, soak in 10 times the volume (v:w) of 95% ethanol for 12 hours, filter, repeat the treatment twice, combine the two filtrates to concentrate for later use; the filter residue is placed in a cool place Ethanol was evaporated in a ventilated place, and then dried in an oven at 50°C to obtain a clematis pretreatment powder.

[0048] (3) Accurately weigh 20.00 g of Clematis clematis pretreated powder, add distilled water at a liquid-to-solid ratio of 1:30 (g:mL), bathe in water at 70°C for 90 minutes, filter with suction, and extract repeatedly 4 times. Combine 4 filtrate polysaccharide extracts.

[0049] (4) The polysaccharide extract is fixed to volume, and the total sugar and reducing sugar content in the extract are det...

Embodiment 3

[0051] (1) Take the whole clematis herb, wash it, drain the water in a cool and ventilated place, dry it at 50°C, and pass it through a 40-mesh sieve to obtain clematis powder.

[0052] (2) Accurately weigh a certain amount of clematis whole herb powder 50.00g, soak in 10 times the volume (v:w) of 95% ethanol for 12 hours, filter, repeat the treatment twice, combine the two filtrates to concentrate for later use; the filter residue is placed in a cool place Ethanol was evaporated in a ventilated place, and then dried in an oven at 50°C to obtain a clematis pretreatment powder.

[0053] (3) Accurately weigh 25.00 g of Clematis clematis pretreated powder, add distilled water at a liquid-to-material ratio of 1:30 (g:mL), bathe in water at 70°C for 90 minutes, filter with suction, and extract repeatedly 4 times. Combine 4 filtrate polysaccharide extracts.

[0054] (4) The polysaccharide extract is fixed to volume, and the total sugar and reducing sugar content in the extract are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com