A kind of preparation method of mofs-graphene composite material

A composite material and graphene technology, applied in the field of porous materials and nanomaterials, can solve the problems of high temperature requirements, low porosity, loss of platinum particles, etc., and achieve the effects of less dosage, short time and mild reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] To prepare graphite oxide, the specific steps are as follows:

[0039] Add 2.5g NaNO 3 and 120ml concentrated sulfuric acid, stir evenly, then add 5g graphite powder, after stirring for 30min, slowly add 15gKMnO 4 Powder, control the system temperature at 0-5°C, and react at low temperature for 2 hours. Transfer the beaker to a water bath, stir at 35°C for 2h, then add 420mL of deionized water, raise the temperature of the system to 98°C for 30min, add 40mL of H 2 o 2 , and then washed with deionized water, centrifuged, and freeze-dried to obtain solid powdered graphite oxide.

Embodiment 2

[0041] Prepare reduced graphene oxide (rGO), the specific steps are as follows:

[0042] Taking THF as the reaction medium, the graphite oxide obtained in Example 1 is used as a raw material to prepare reduced graphene oxide (rGO), and the specific steps are as follows:

[0043] Get 0.4g graphite oxide (made by embodiment 1), be placed in 40mL THF and ultrasonically disperse 30min to obtain graphene oxide dispersion liquid; 4 Dissolve in 10ml of methanol, and add it dropwise to the graphene oxide dispersion with a constant pressure dropping funnel, react in an ice-water bath at 5°C for 4h, then raise the temperature of the system to 60°C for 1h, wash with a small amount of deionized water and methanol centrifuge, Obtained reduced graphene oxide (in the form of a slightly wet solid powder).

[0044] The reduced graphene oxide prepared in this example was vacuum-dried at 60° C. for 20 hours and then weighed to 0.2 g, thus measuring: the quality of the product reduced graphene o...

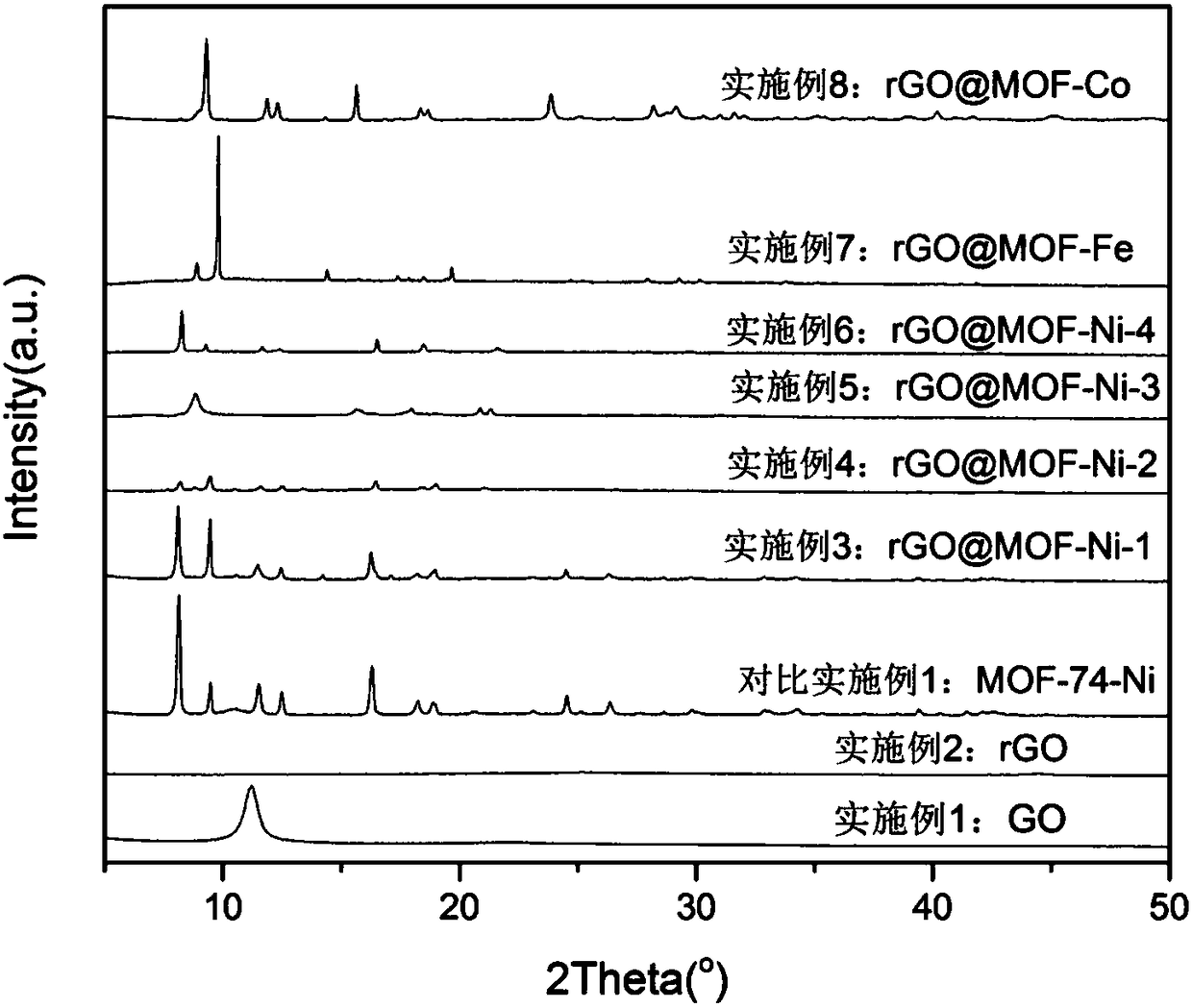

Embodiment 3

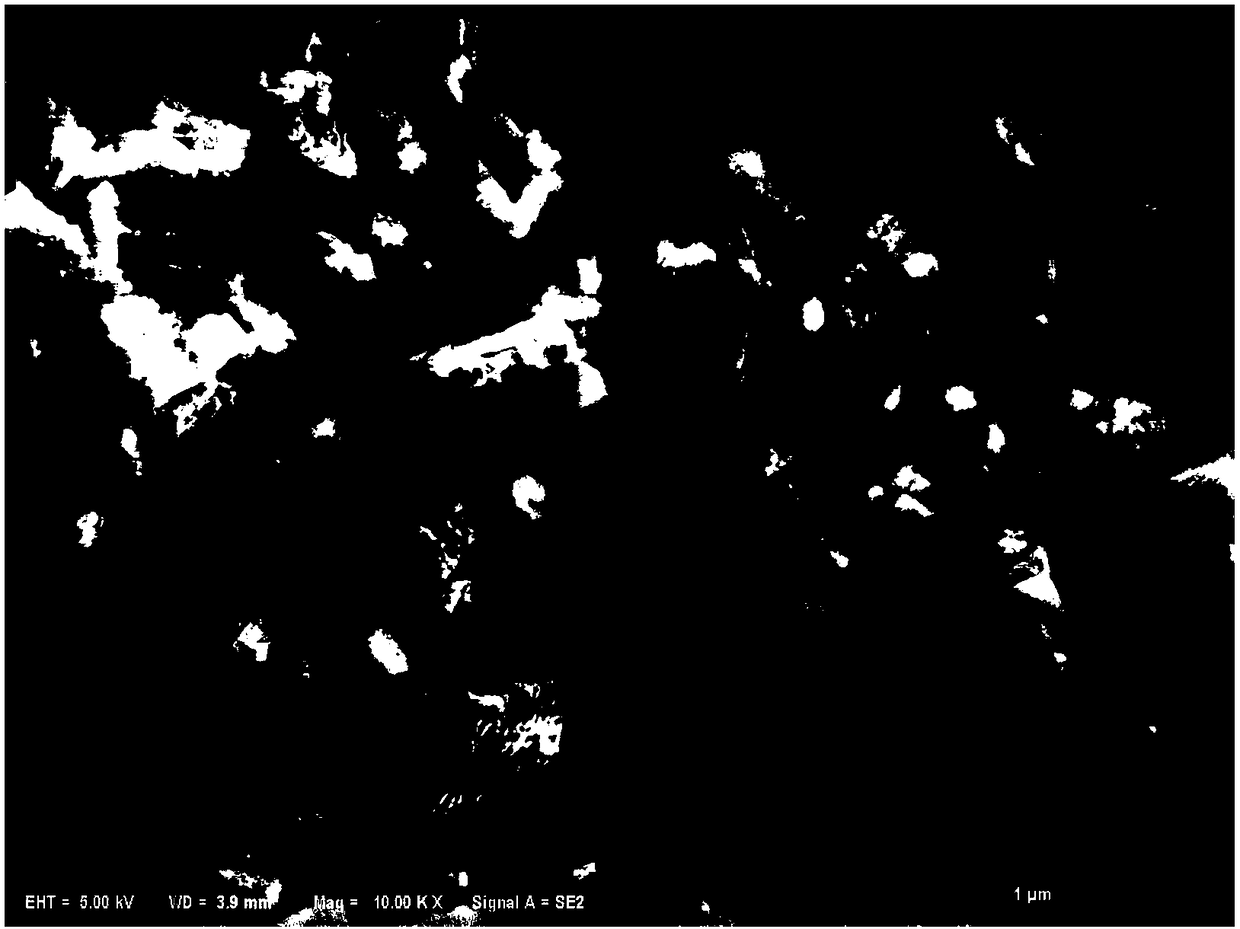

[0046] Preparation of rGO@MOF-Ni composite material (graphene / Ni-organic framework composite material), the specific steps are as follows:

[0047] 1) prepare graphene: concrete steps are the same as embodiment 2, just change the consumption of raw material graphite oxide into 0.6g, make reduced graphene oxide (being slightly wet solid powder).

[0048] 2) Mix the reduced graphene oxide prepared in step 1) with 0.582g (2mmol) Ni(NO 3 ) 2 ·6H 2 O, 0.332g (2mmol) H 2 Add BDC and 0.224g (1mmol) DABCO to 20mL THF / H 2 O / CH 3 OH (volume ratio: 3:1:1) mixed solution, ultrasonically stirred for 1 h, and then reacted at 110 °C for 72 h in the reactor, then heated with THF, slightly heated CH 3 OH was washed three times each, and vacuum-dried at 90°C for 20 h to obtain rGO@MOF-Ni (mark this sample as rGO@MOF-Ni-1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com