Preparation method and application of polyacrylonitrile-acrylic acid high-molecular material

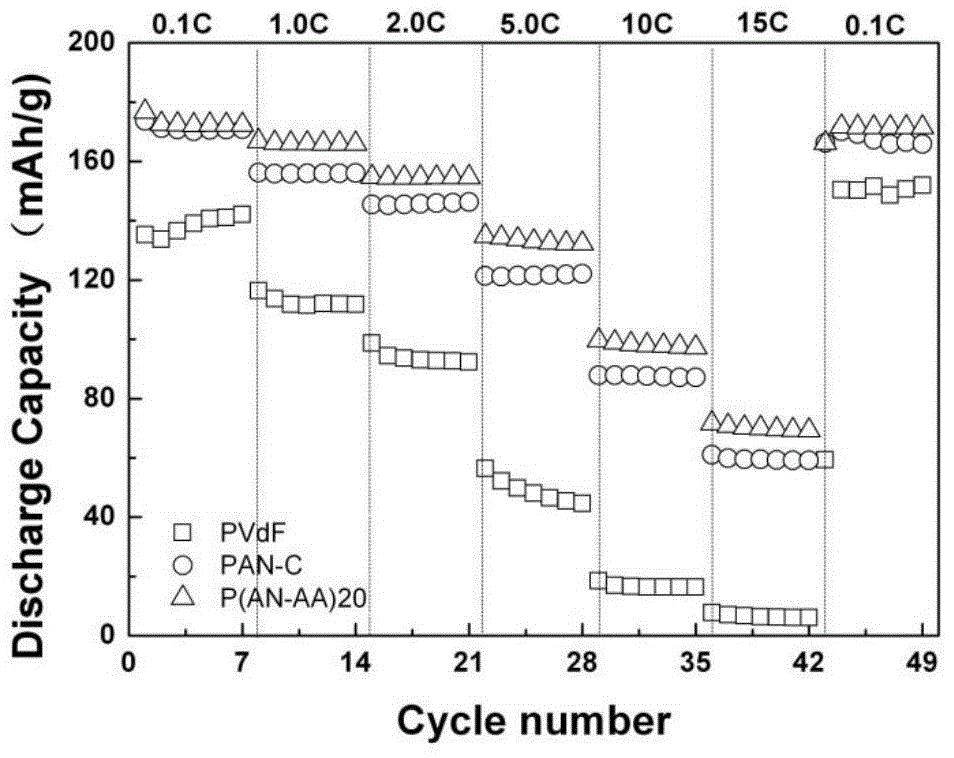

A polymer material, polyacrylonitrile technology, used in electrical components, circuits, battery electrodes, etc., can solve the problem that the adhesion of the pole piece is not very high, the negative pole piece cannot be stable, and the walking performance of the negative slurry is not very stable. and other problems to achieve the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

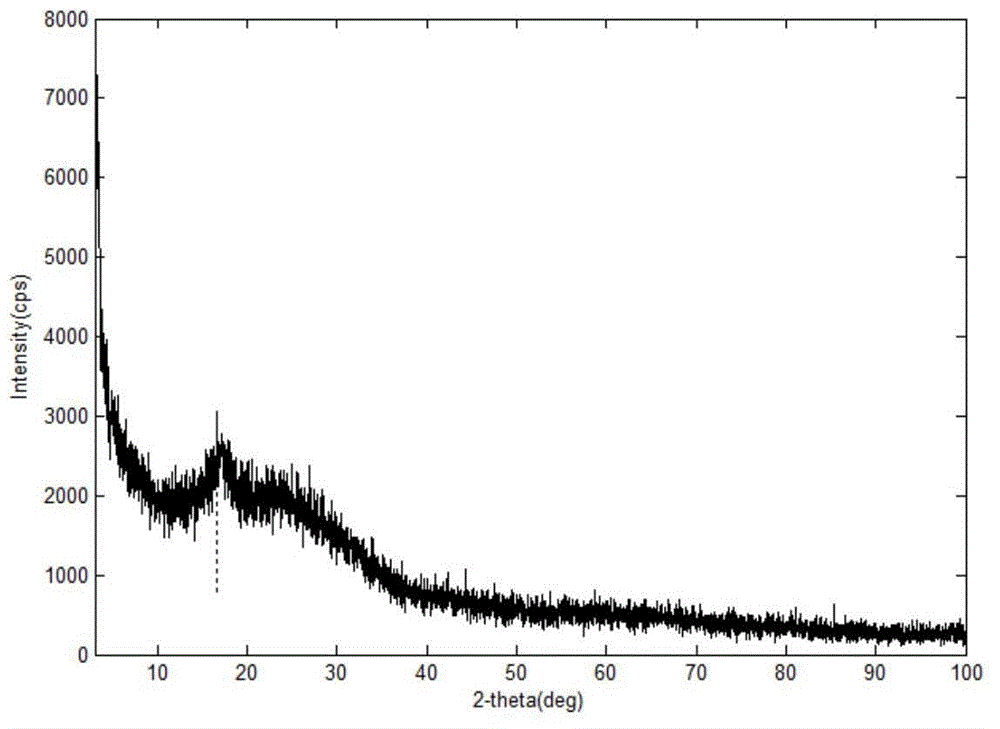

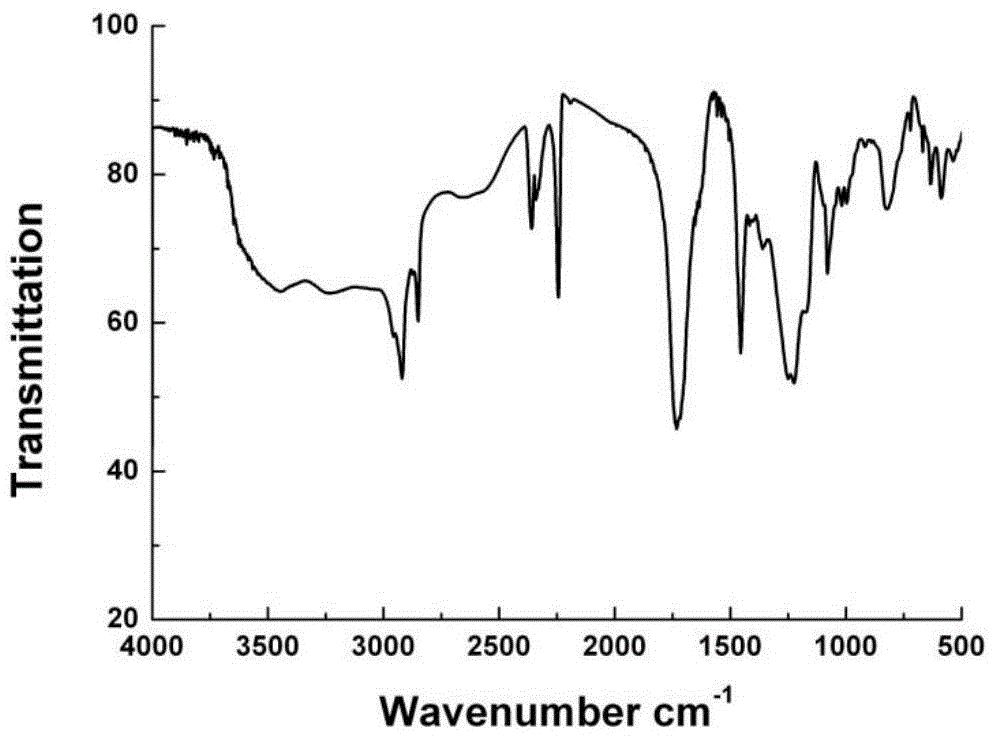

[0028] The steps in the production stage of polyacrylonitrile-acrylic acid polymer materials are as follows:

[0029] Step 1, initial feeding stage: Weigh distilled water, emulsifier sodium dodecyl sulfate (SDS), and monomeric acrylic acid according to the ratio of mass fraction 69.25:0.6:20 and add them to the reactor, stirring at a speed of 200rmp The side water bath was heated to 65°C.

[0030] Step 2, initiation stage: add 0.15% initiator KPS at a rate of 15 ml / h, and continue stirring at constant temperature for 30 minutes.

[0031] Step 3, emulsification reaction stage: add 10% monomeric acrylonitrile at a rate of 10 ml / h. The mass ratio of acrylic acid to acrylonitrile is 20:10. After all the monomers were added, the stirring was continued, and the reaction was continued for 2 hours in the reactor.

[0032] Step 4, aging stage: raise the temperature to 70° C. and continue stirring for 1 hour to stop the reaction.

[0033] Step 5, taking out the sample: after the sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com