a spoiled mg 2 Composite Treatment Method for Microstructure of Si/Fe-Rich Aluminum Matrix Composites

An aluminum-based composite material and a composite treatment technology, which is applied in the treatment field of Mg2Si/Fe-rich aluminum-based composite materials, can solve the problems of reducing the quality of scrap aluminum, reducing Fe content in aluminum, and matrix splitting, etc., and achieves low cost and easy operation. , the effect of obvious metamorphism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

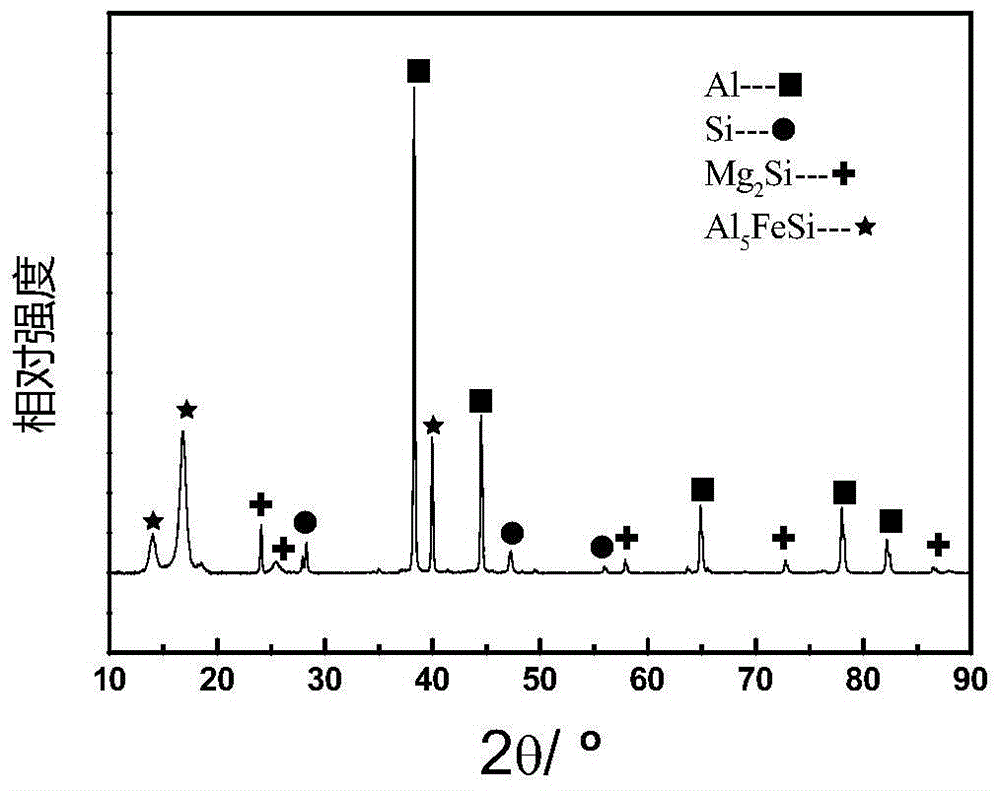

[0083] Example 1 B-Cr vs. 20% Mg 2 Composite modification of Si / Fe-rich Al matrix composites

[0084] First, the specific composition of the Fe-rich aluminum alloy was determined by ICP direct-reading spectroscopy, in which the mass percentage of Si was 7%, the mass percentage of Fe was 1.3%, and the rest was mainly Al. Mg in this example 2 Si-reinforced particles are produced in situ inside the aluminum alloy by melting pure magnesium and Al-20Si master alloy together with the raw materials. The components and mass percentages of the refined modifier added in this embodiment are: B: 0.2%, Cr: 0.8%.

[0085] This embodiment modifies Mg 2 The specific operation method of the composite treatment technology of Si / Fe-rich aluminum matrix composite structure is as follows:

[0086] (1) First, preheat a certain amount of Fe-rich aluminum alloy, pure magnesium, and Al-20Si master alloy at 300°C for 5 minutes, then raise the temperature to 720°C and keep it for 20 minutes. After t...

Embodiment 2

[0091] Example 2 B-Cr vs. 20% Mg 2 Composite modification of Si / Fe-rich Al matrix composites

[0092] The modification operation process adopted in this embodiment is basically the same as that in Example 1, the difference is the content of the modification agent added. The components and mass percentages of the refined modifier added in this embodiment are: B: 0.2%, Cr: 1.0%.

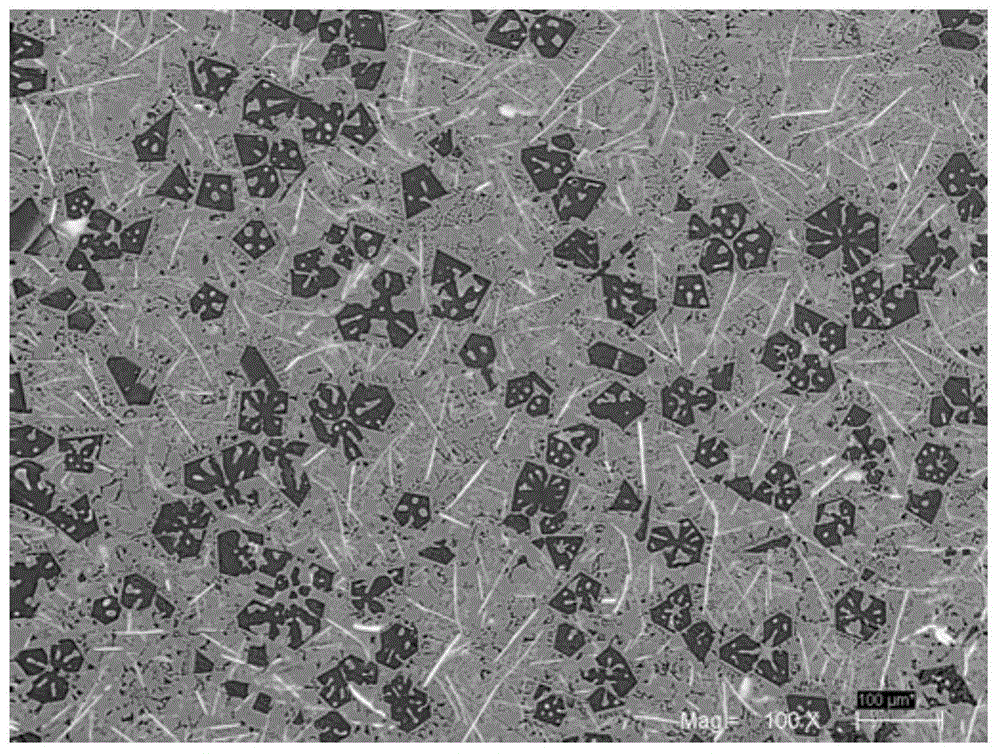

[0093] Figure 12 It is the Mg after the treatment of the multi-element composite refinement modificator adopted in the present embodiment 2 SEM photos of Si / Fe-rich aluminum matrix composites, comparison figure 2 Unmodified Mg 2 Si / Fe-rich aluminum matrix composite material, it can be seen that all the long needle-like β-Fe phases have transformed into skeletal α-Fe phases, the length of Fe has hardly changed, but the width has increased by nearly 10 times, and the aspect ratio has changed from 20.4 Reduced to 3.3. Primary Mg after modification 2 The Si phase is regular polygonal, evenly distr...

Embodiment 3

[0094] Example 3 B-Cr vs. 20% Mg 2 Composite modification of Si / Fe-rich Al matrix composites

[0095] The modification operation process that present embodiment adopts is basically the same as embodiment 1, and difference is the content of the modification agent that adds. The components and mass percentages of the refined modifier added in this embodiment are: B: 0.1%, Cr: 0.8%.

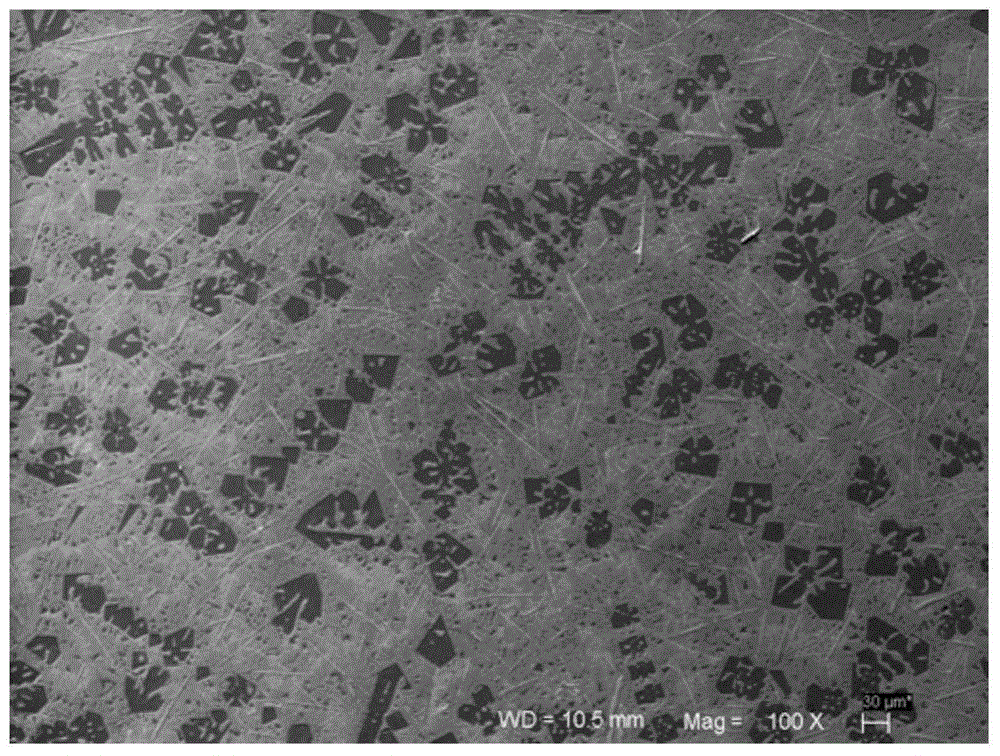

[0096] Figure 13 It is the Mg after the treatment of the multi-element composite refinement modificator adopted in the present embodiment 2 SEM photos of Si / Fe-rich aluminum matrix composites, comparison figure 2 Unmodified Mg 2 Si / Fe-rich aluminum matrix composite material, it can be seen that the long needle-like β-Fe phases are all transformed into fine Chinese-shaped and bone-like α-Fe phases, the size is reduced, and the aspect ratio is reduced to 2.3 . Primary Mg after modification 2 The Si phase is regular polygonal, evenly distributed, and the average size is about 45 μm, which is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com