Anode structure for increasing exhaust rate of electrolysis gas from aluminum electrolysis cell

A technology of anode structure and gas discharge, which is applied in the field of anode structure to improve the discharge rate of electrolytic gas in aluminum electrolytic cells, can solve the problem that the probability of gas entering the electrolyte interface is high, the gas is difficult to discharge the upper space of the electrolytic cell, and the number of anodes in large aluminum electrolytic cells can be solved. Too many problems, to achieve the effect of being conducive to downward dissolution, reducing non-conducting time, and reducing the consumption of fluoride salts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

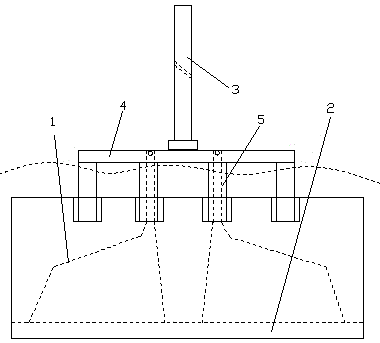

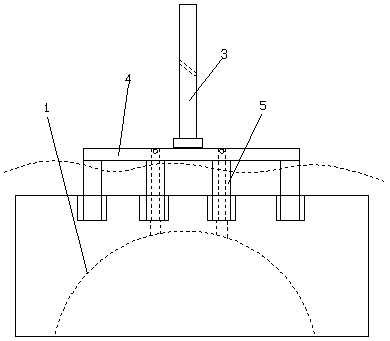

[0021] An anode structure for improving the discharge rate of electrolytic gas from an aluminum electrolytic cell, the anode structure includes an anode assembly 1 and a guide rod assembly, the anode assembly 1 and the guide rod assembly are fixedly connected, a groove 2 is opened at the bottom of the anode assembly 1, and the anode A through hole is opened in the carbon bowl in the middle of the assembly 1. The guide rod assembly includes a guide rod 3, a beam 4 and a plurality of steel claws 5. Among the plurality of steel claws 5, two steel claws 5 corresponding to the carbon bowl are Offer through holes respectively, also can offer through holes on all steel claws 5, also offer through holes on the described beam 4, the flue gas in the electrolyzer becomes negative pressure and CO 2 Gas extraction to reduce CO in the electrolyte 2 Gas concentration, thereby reducing the secondary reaction, the groove 2 is filled with wood chips or bamboo chips, the filling depth is 50mm, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com