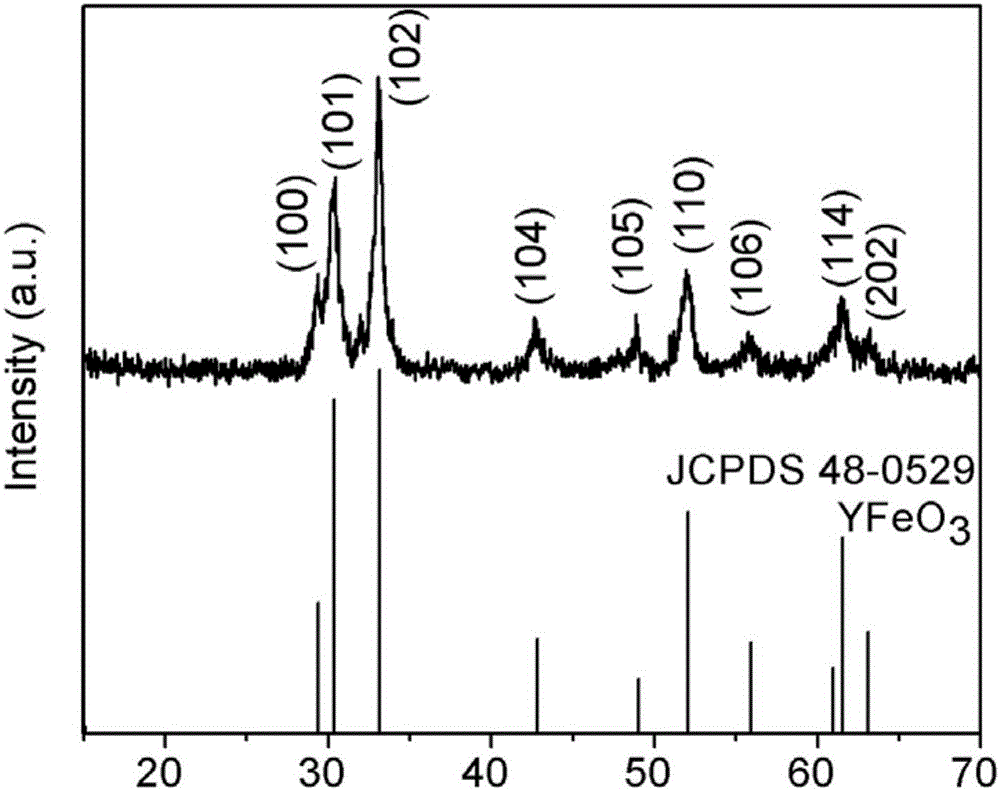

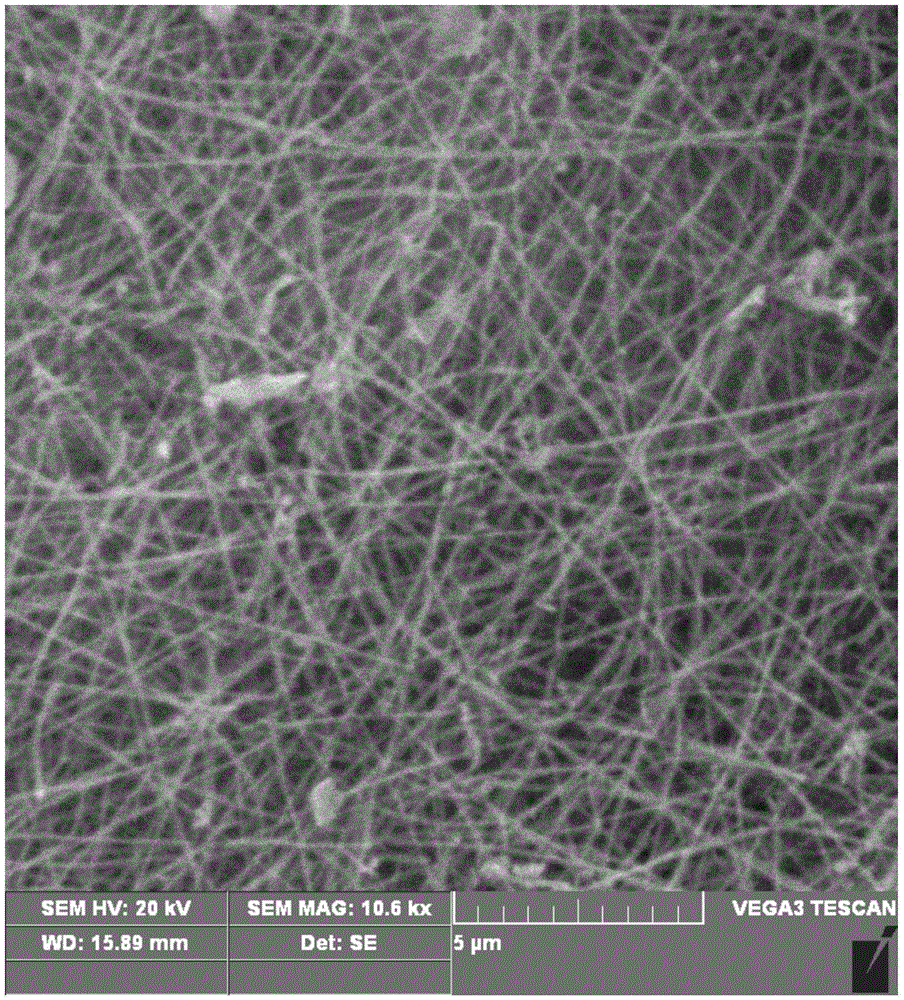

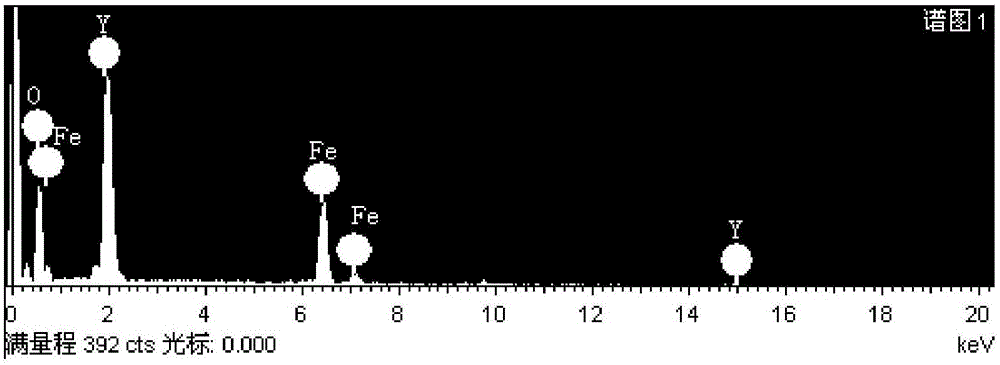

Preparation method of multiferroic YFeO3 nano-fiber

A technology of nanofibers and yttrium ferrite, which is applied in the field of nanomaterials and can solve the problems of nanofiber research and reports that have not yet been discovered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method of the present embodiment multiferroic yttrium ferrite nanofiber comprises the following steps:

[0025] Step 1, preparation of spinning solution: take by weighing 1.818g of analytically pure iron nitrate Fe (NO 3 ) 3 9H 2 O and 1.7235g of analytically pure yttrium nitrate Y (NO 3 ) 3 ·6H 2 O (that is, the molar ratio of the two is 1:1) was added to 30g of DMF solvent, stirred with a magnetic stirrer for 1h to fully dissolve ferric nitrate and yttrium nitrate, then added 2.28g of PVP, and then continued to stir with a magnetic stirrer for 4h at a constant temperature. Realize thorough mixing, obtain spinning solution; The relative molecular mass Mr of described PVP=1.3×10 6 ;

[0026] Step 2, electrospinning: use the electrospinning apparatus with the receiving device as the drum to perform electrospinning on the spinning liquid, the specific process is: put the syringe with a 0.7mm diameter stainless steel needle on the bracket, adjust the ...

Embodiment 2

[0033] The preparation method of the present embodiment multiferroic yttrium ferrite nanofiber comprises the following steps:

[0034] Step 1, preparation of spinning solution: take by weighing 1.818g of analytically pure iron nitrate Fe (NO 3 ) 3 9H 2 O and 1.7235g of analytically pure yttrium nitrate Y (NO 3 ) 3 ·6H 2 O (that is, the molar ratio of the two is 1:1), was added to 25g of DMF solvent, stirred with a magnetic stirrer for 1h to fully dissolve ferric nitrate and yttrium nitrate, then added 2.4g of PVP, and then continued to stir with a magnetic stirrer for 4h To achieve thorough mixing to obtain spinning solution; the relative molecular mass Mr of the PVP=1.3×10 6 ;

[0035] Step 2, electrospinning: use the electrospinning apparatus with the receiving device as the drum to perform electrospinning on the spinning liquid, the specific process is: put the syringe with a 0.7mm diameter stainless steel needle on the bracket, adjust the receiving device The distan...

Embodiment 3

[0039] The preparation method of the present embodiment multiferroic yttrium ferrite nanofiber comprises the following steps:

[0040] Step 1, preparation of spinning solution: take by weighing 2.02g of analytically pure iron nitrate Fe(NO 3 ) 3 9H 2 O and 1.915g of analytically pure yttrium nitrate Y (NO 3 ) 3 ·6H 2 O (that is, the molar ratio of the two is 1:1), was added to 25.5g of DMF solvent, stirred with a magnetic stirrer for 1h to fully dissolve the ferric nitrate and yttrium nitrate, then added 1.9g of PVP, and then continued to stir at a constant temperature with a magnetic stirrer 4h to realize thorough mixing to obtain spinning solution; the relative molecular mass Mr=1.3×10 of the PVP 6 ;

[0041] Step 2, electrospinning: use the electrospinning apparatus with the receiving device as the drum to perform electrospinning on the spinning liquid, the specific process is: put the syringe with a 0.7mm diameter stainless steel needle on the bracket, adjust the rec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com