Composite geomembrane and manufacturing method thereof

A technology of composite geomembrane and manufacturing method, which is applied in chemical instruments and methods, artificial waterways, sea area engineering, etc., can solve the problems that composite geomembrane is prone to wrinkles and wrinkles, and achieves convenient laying, no wrinkle resistance, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

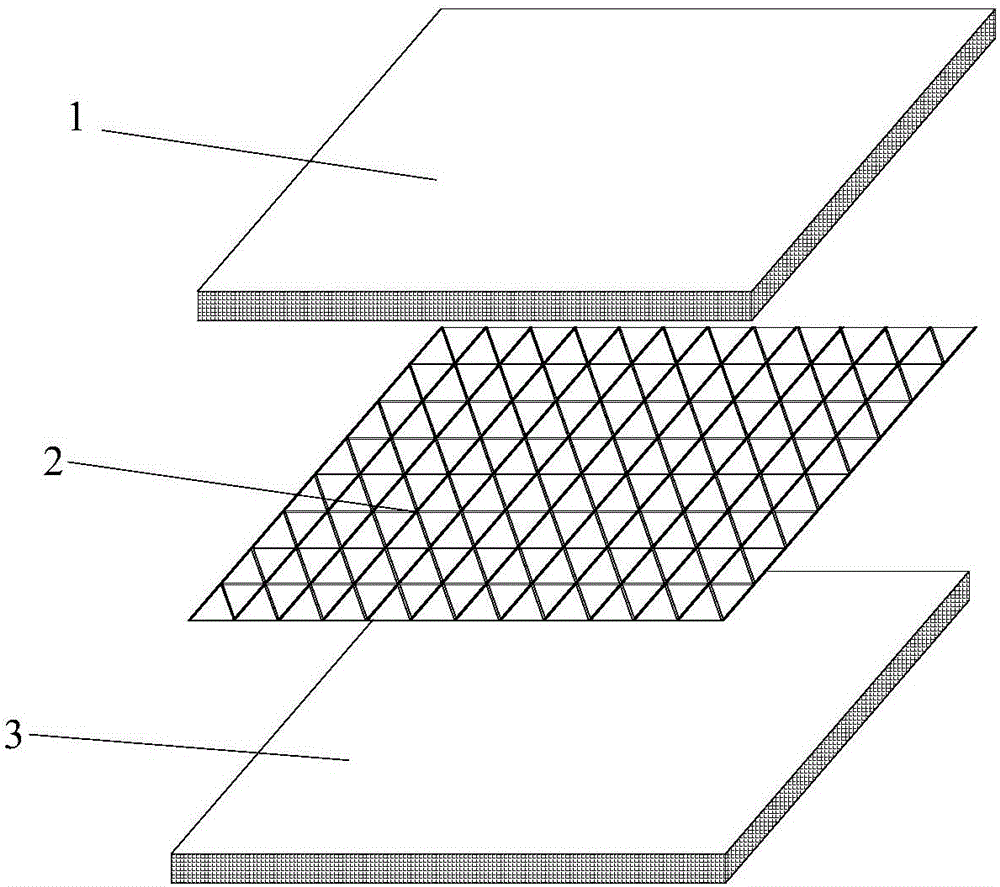

[0028] Mix 6.5 parts of HDPE, 3.5 parts of carbon black, 0.5 parts of anti-aging agent, 3 parts of antioxidant, 2.5 parts of ultraviolet absorber, and 4 parts of stabilizer; then mix 88 parts of PP, 9 parts of talcum powder, and 2 parts of toughening agent , 0.4 part of antioxidant, 0.2 part of UV531 anti-ultraviolet, and 0.4 part of polyethylene wax are mixed uniformly; the raw materials of the two mixtures are heated and co-extruded by a twin-screw extruder to obtain the first waterproof layer 1 and anti-wrinkle layer 2 respectively, and extruded The obtained first waterproof layer 1 and anti-wrinkle layer 2 are preliminarily compounded by calendering; 86.5 parts of HDPE, 3.5 parts of carbon black, 0.5 parts of anti-aging agent, 3 parts of antioxidant, 2.5 parts of ultraviolet absorber, stabilizer 4 parts are mixed evenly, and the uniformly mixed raw materials are heated and extruded by a screw extruder to obtain the second waterproof layer 3. The extruded second waterproof l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com