An internal combustion engine device with double-sleeved electrodes using water as fuel

An internal combustion engine, double-sleeve technology, applied to internal combustion piston engines, adding non-fuel substances to fuel, combustion engines, etc., can solve problems such as waste, ecological environment damage, and energy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

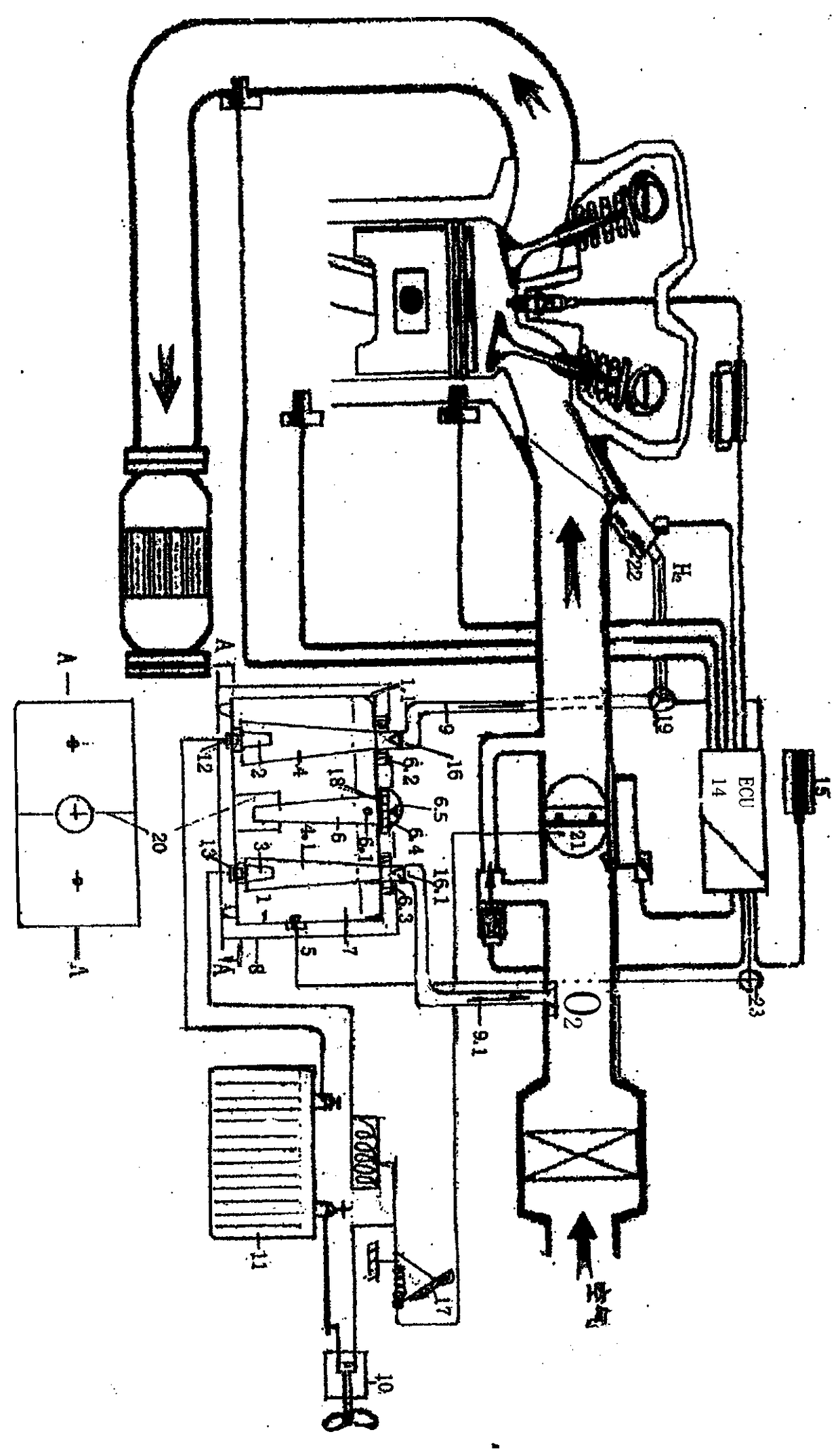

[0029] At first, brief the content structure of the present invention: comprise electrolyzer 1, master start switch 10, foot-operated composite throttle type current controller 17 and control transmission bar member; Be provided with cathode graphite electrode 2, anode titanium Alloy electrode 3 has cathode sleeve 4 on cathode graphite electrode 2, and by hydrogen delivery pipe 9, there are check valve 16 and hydrogen fuel booster pump 19 in which hydrogen (H 2 ) into the automobile electric injector 22; the pressure of the booster pump 19 is controlled by the ECU14, and there is an anode titanium alloy electrode 3 on the right side of the electrolytic tank 1 with an anode sleeve 4.1 fixed on the electrolytic tank with an anode sleeve nut 6.3 The main cover 1.1 of the electrolytic cell on the upper part of the tank 1 is connected to the oxygen delivery pipe 9.1,

[0030] Among them, there is an oxygen delivery check valve 16.1 which can directly deliver the oxygen produced to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com