Thin film acoustic metamaterial silencer and designing method thereof

An acoustic metamaterial, muffler technology, applied in mechanical equipment, pipes/pipe joints/pipes, pipe components, etc., can solve the problems of pipeline noise, single working frequency, small size of the muffler, etc., to widen the working frequency and clear the working frequency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

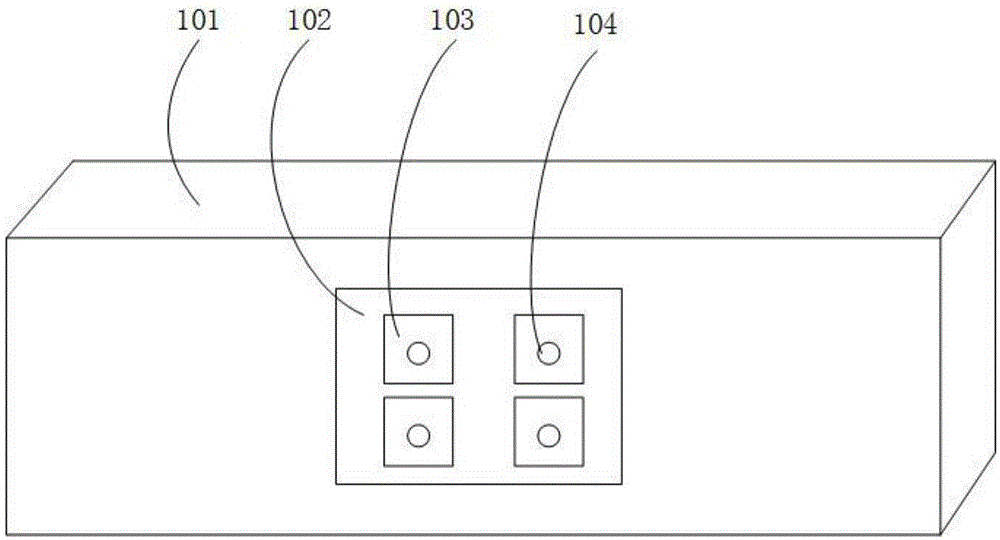

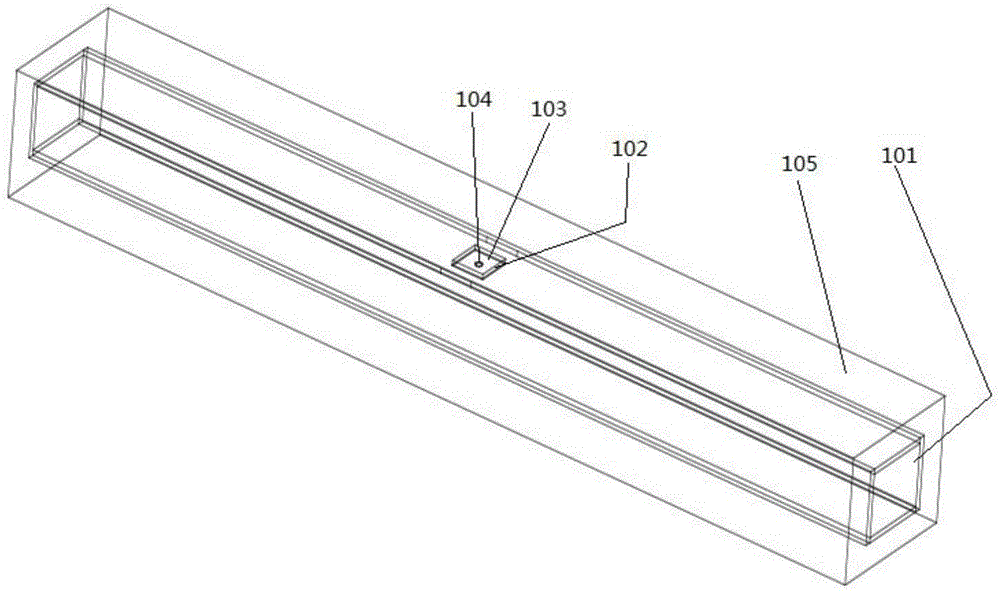

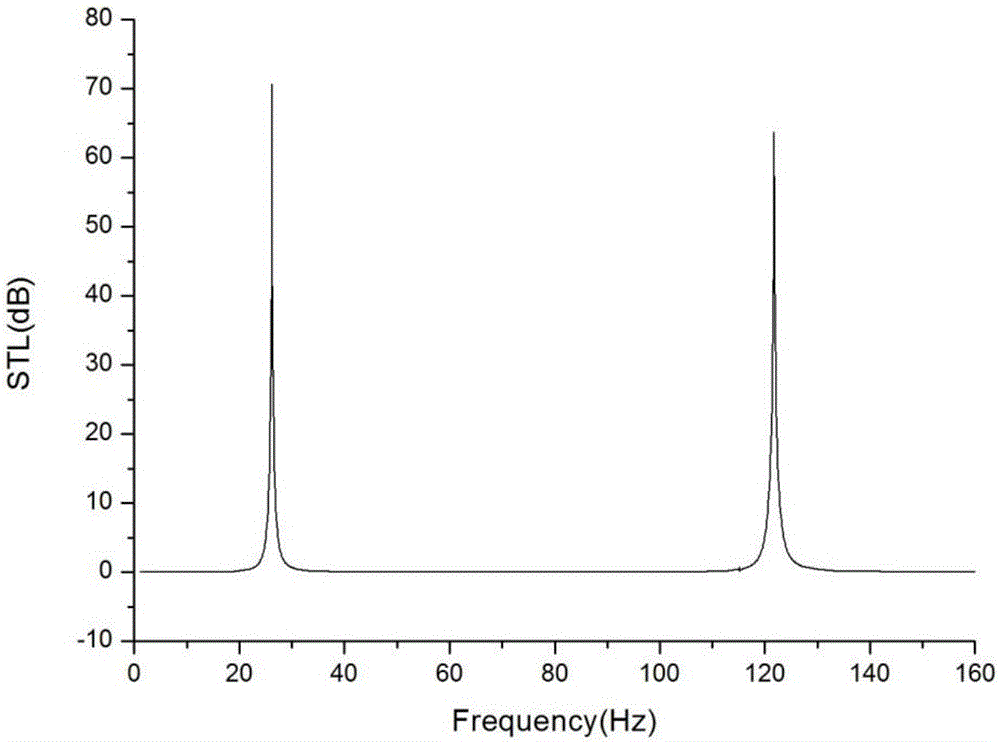

[0034] See figure 1 , A membrane acoustic metamaterial muffler, the main technical feature is to add a single or multilayer acoustic metamaterial unit cell in the pipeline. The unit cell is composed of a membrane 103 and a mass 104, and the unit cell is fixed on the muffler frame 102. The muffler frame 102 is fixed on the pipeline 101, and the structural parameters are changed according to the required noise reduction frequency, so that the muffler forms a dynamic absorber system with the pipeline air at the working frequency, which improves the noise reduction and noise reduction effect of the pipeline, and reduces The volume of the muffler. The specific implementation plan is as follows:

[0035] The membrane acoustic metamaterial muffler structure designed in the present invention includes a pipe 101; the side of the pipe 101 is provided with a muffler frame 102, the muffler frame 102 is provided with a film 103, and the center of the film 103 is provided with a mass 104. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com