Laser diode area array pumped uniformity detection apparatus

A laser diode and detection device technology, applied in the laser field, can solve the problems of low accuracy of detection results, achieve high accuracy and ensure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

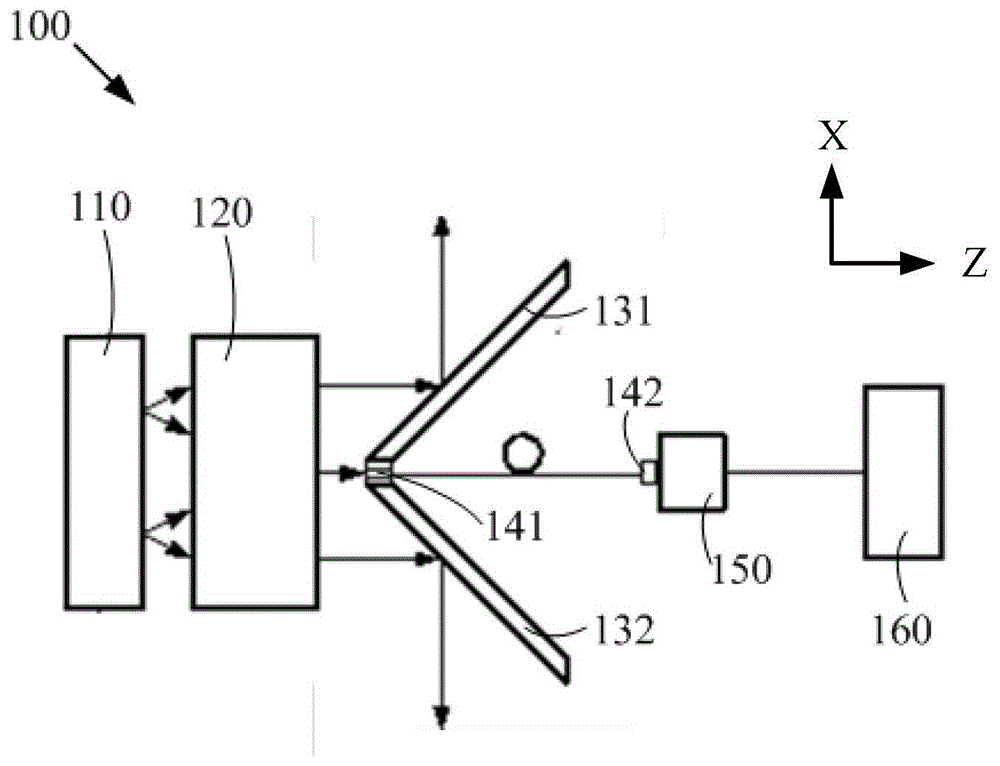

[0020] see figure 1 , figure 1 It is a structural schematic diagram of an embodiment of a laser diode area array pumping uniformity detection device in an embodiment of the present invention. Such as figure 1 As shown, the laser diode array pump light uniformity detection device 100 includes a laser diode array 110, an optical waveguide 120, a V-shaped reflector (including reflector 131 and reflector 132), a laser transmission fiber (including optical fiber connector 141 and fiber end 142), a driver (not shown), a power meter probe 150 and a processor 160.

[0021] Such as figure 1 As shown, the horizontal direction of the paper is the z direction, the vertical direction of the paper is the x direction, and the direction perpendicular to the paper is the y direction. Specifically, the LD (Laser Diode, laser diode) array can be formed by stacking several LD arrays along the x direction, the fast axis direction of the laser diode array is the y direction, and the slow axis...

Embodiment 2

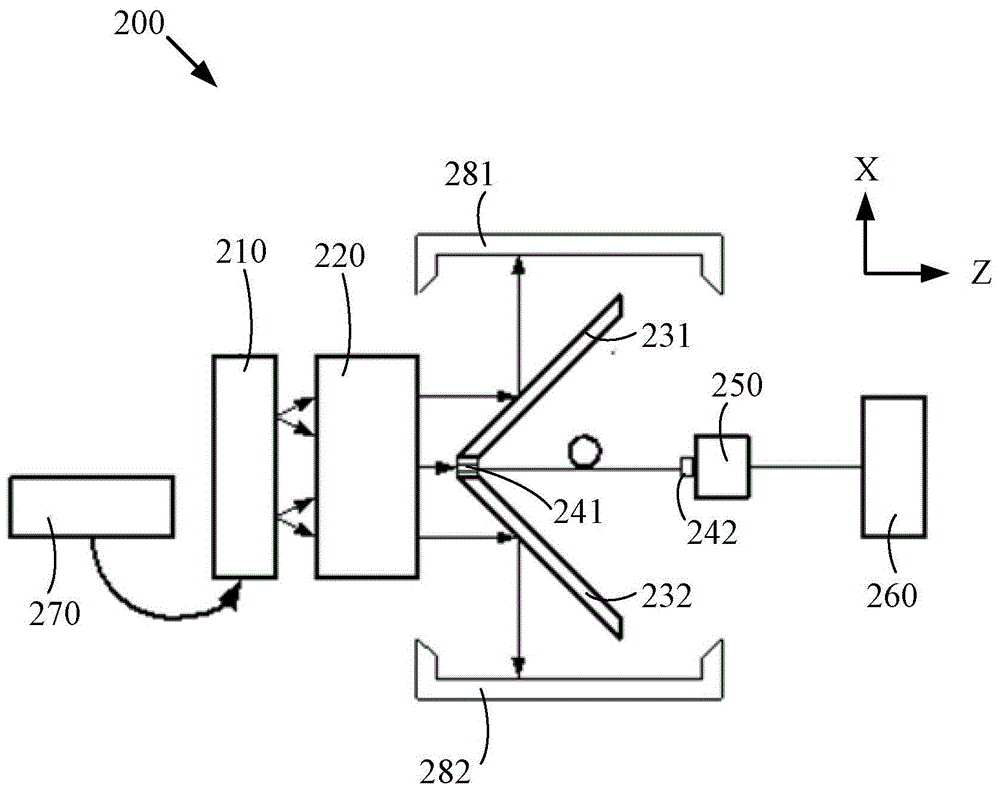

[0035] see figure 2 , figure 2 It is a structural schematic diagram of another embodiment of a laser diode area array pumping uniformity detection device in the embodiment of the present invention. Such as figure 2 As shown, a laser diode array pump uniformity detection device 200 includes a laser diode array 210, an optical waveguide 220, a V-shaped reflector (including reflector 231 and reflector 232), laser transmission optical fiber (including optical fiber connector 241 and fiber end 242), a driver (not shown), a power meter probe 250 and a processor 260.

[0036] The differences between this embodiment and Embodiment 1 include:

[0037] 1. A laser diode array pumping uniformity detection device 200 also includes a water cooler 210 for cooling the laser diode array 210, especially suitable for high-power laser diode arrays.

[0038] 2. A laser diode area array pumping uniformity detection device 200 further comprising two light receiving plates 281 and 282 respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com