High-temperature testing clamp of piezoelectric polarization device

A test fixture and piezoelectric technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of small-sized samples that cannot be polarized, waste of polarized silicone oil, and inconvenient operation, and achieve good fixing effect and easy operation , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

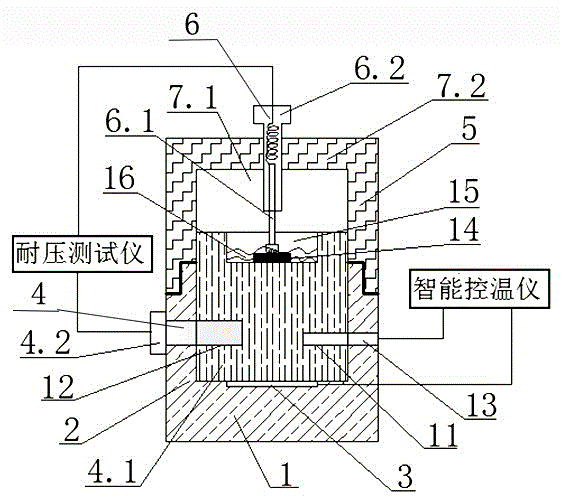

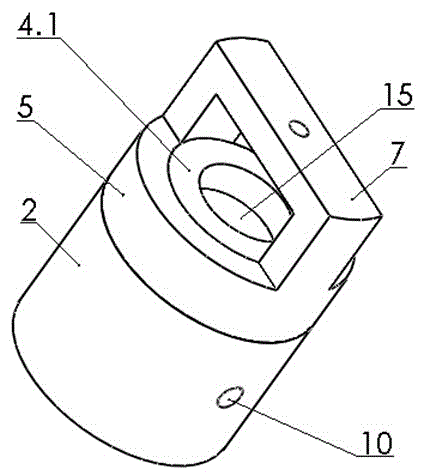

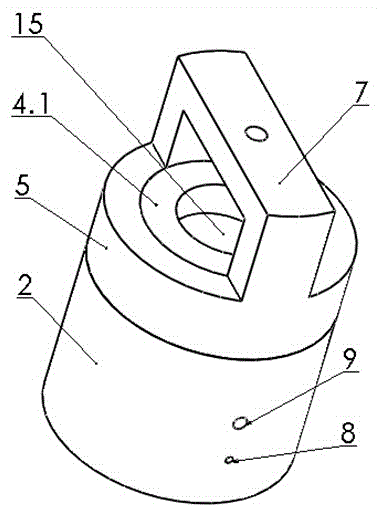

[0019] Such as Figure 1-3 As shown, the high temperature test fixture of the piezoelectric polarization device of the present invention includes a support base 1, a lower sheath 2, a heating element 3, a lower electrode 4, an upper sheath 5 and an upper electrode 6, and the support base 1 and the lower The sheath 2 forms an organic whole, the support base 1 is provided with a card slot, the heating element 3 is a circular ceramic heating chip, and the circular ceramic heating chip is installed in the card slot, and the lower electrode 4 It includes a copper column 4.1 with a circular groove on the upper end and a threaded rod terminal 4.2. The copper column 4.1 is installed on the support base 1 and is closely attached to the ceramic heating chip. The upper sheath 5 is provided with cutouts on both sides of the upper end 7.1, the up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com