Optical image-taking lens

A lens and optical technology, applied in the field of imaging lens sets, can solve the problems of inability to meet image quality requirements, insufficient lens resolution, limited ultra-wide-angle demand, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments will be described in more detail below with reference to the accompanying drawings; however, these embodiments can be implemented in different forms, and therefore should not be viewed as being limited only to the embodiments presented here. Rather, these embodiments are intended to make this disclosure more thorough and complete, and to fully convey the scope of the invention to those skilled in the relevant arts.

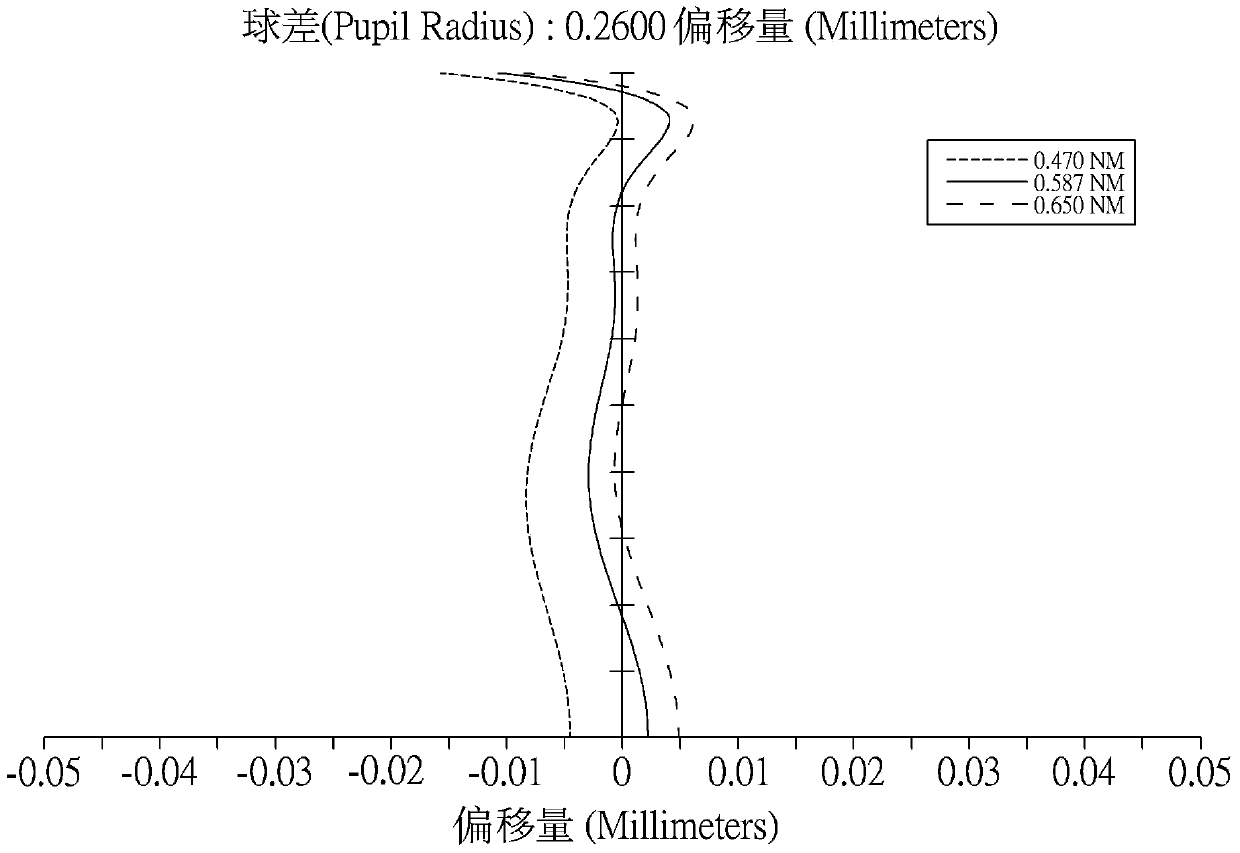

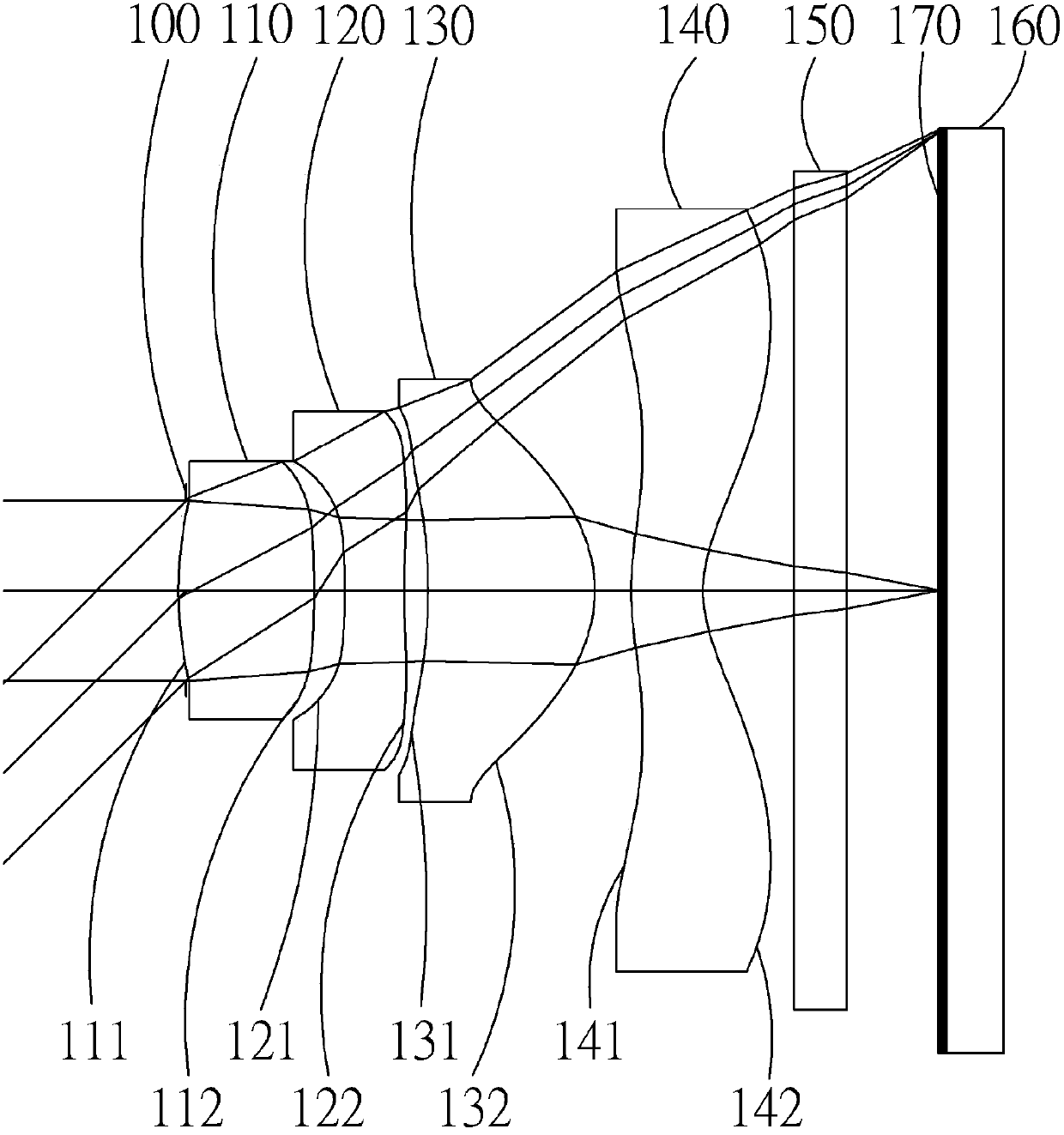

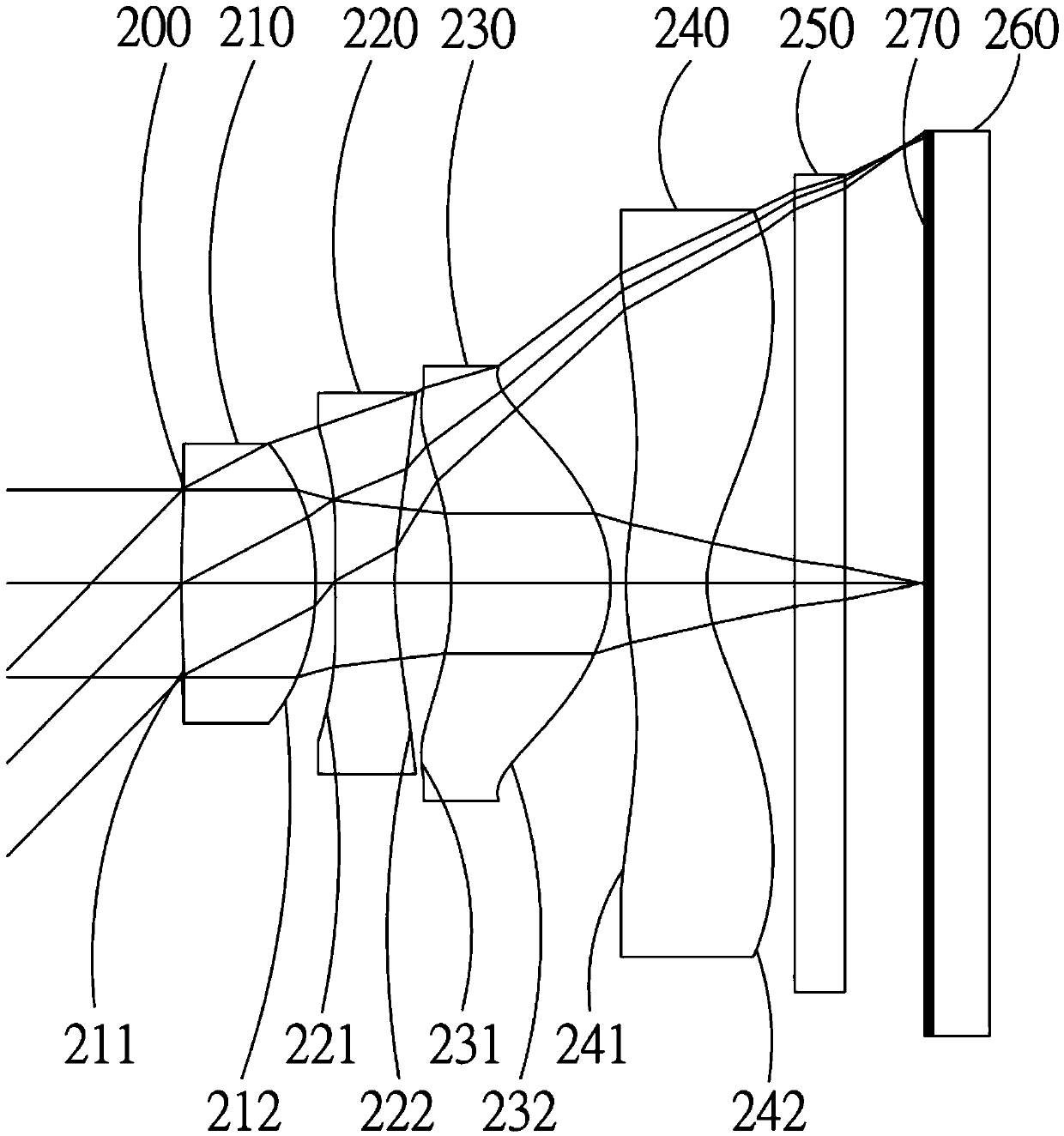

[0031] The invention provides an optical imaging lens. see figure 1 The optical imaging lens includes four lenses, which are arranged along the optical axis from the object side to the image side: a first lens 110 , a second lens 120 , a third lens 130 and a fourth lens 140 . Wherein, the first lens 110 has a positive refractive power; the second lens 120 has a negative refractive power; the third lens 130 has a positive refractive power; the fourth lens 140 has a negative refractive power, and its image side optical surface 142 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com