Ultra-fine cable applied shielding protection sheath film and production technology thereof

A technology of shielding sheath and ultra-thin cable, which is applied in the direction of insulated cable, cable/conductor manufacturing, cable, etc., can solve the problems of inability to meet the requirements of ultra-thin cable, small outer diameter of single-core coaxial cable, and narrow cable space. , to achieve the effect of good shielding function and insulation function, superior protection and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

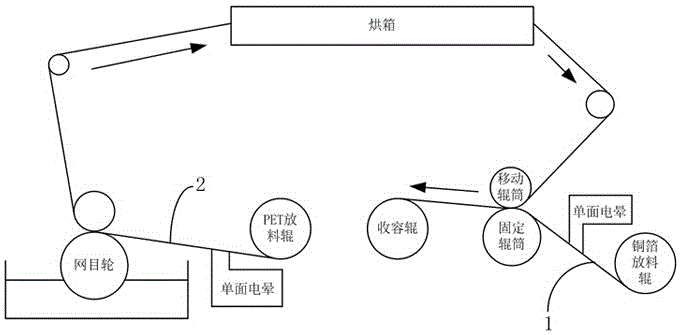

[0037] The invention provides a shielding sheath film applied to ultra-thin cables, which can protect the inner core of the ultra-thin cables, and the shielding sheath film itself has shielding and insulating effects. The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to make it easier to understand and grasp.

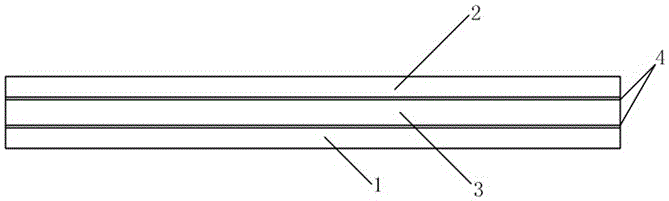

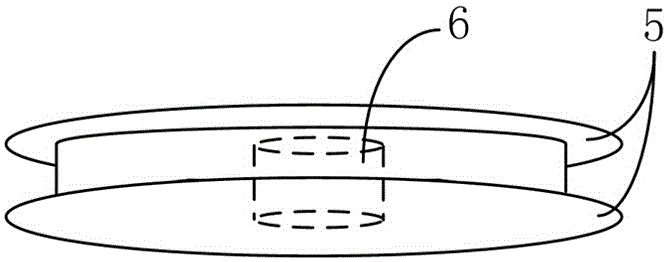

[0038] Such as figure 1 and figure 2 As shown, the structure of the shielding sheath film applied to ultra-fine cables in the present invention includes a copper foil layer 1, a PET layer 2 and an adhesive layer 3 between the copper foil layer 1 and the PET layer 2, and the copper foil layer 1, the PET layer 2 The side of the PET layer 2 facing the adhesive layer 3 has a corona rough surface 4, and the copper foil layer, the adhesive layer and the PET layer are bonded together. Among them, in order to meet the needs of ultra-thin cables, there is a thickness limit for the shielding s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com