Formation method of interconnection structure

A technology of interconnection structure and conductive structure, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems affecting metal conductivity and small grain size, and achieve improved conductivity, high conductivity, and reduced The effect of electron scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

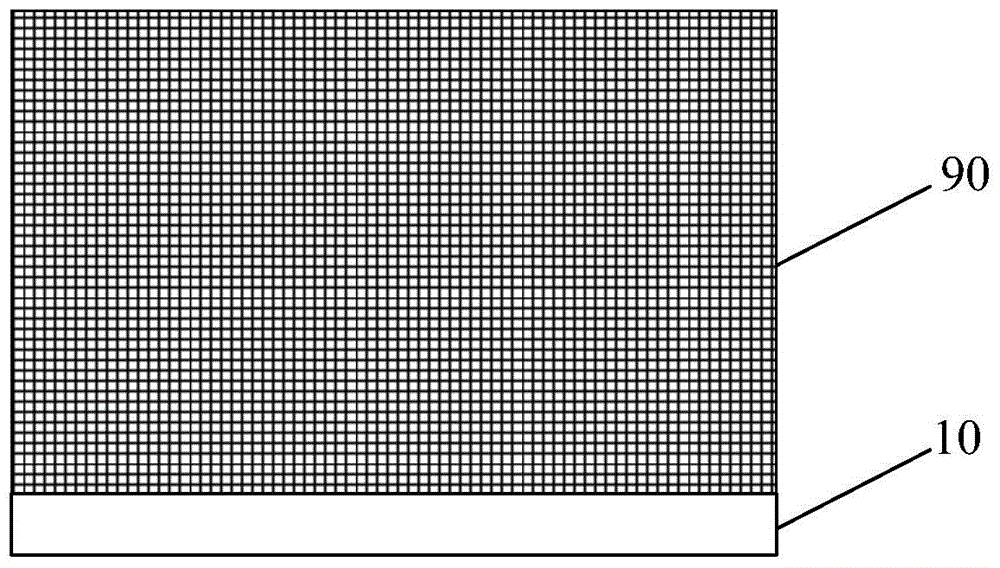

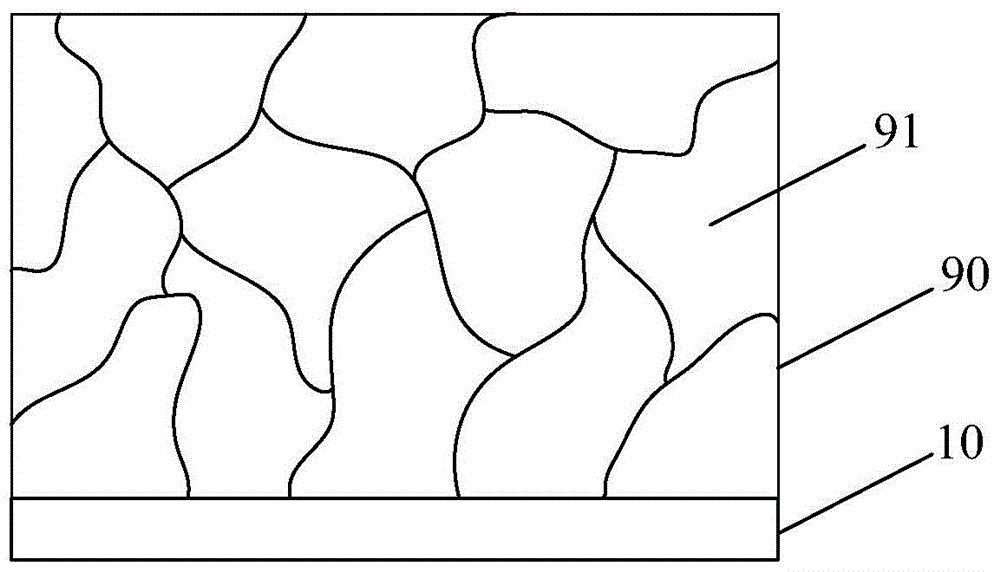

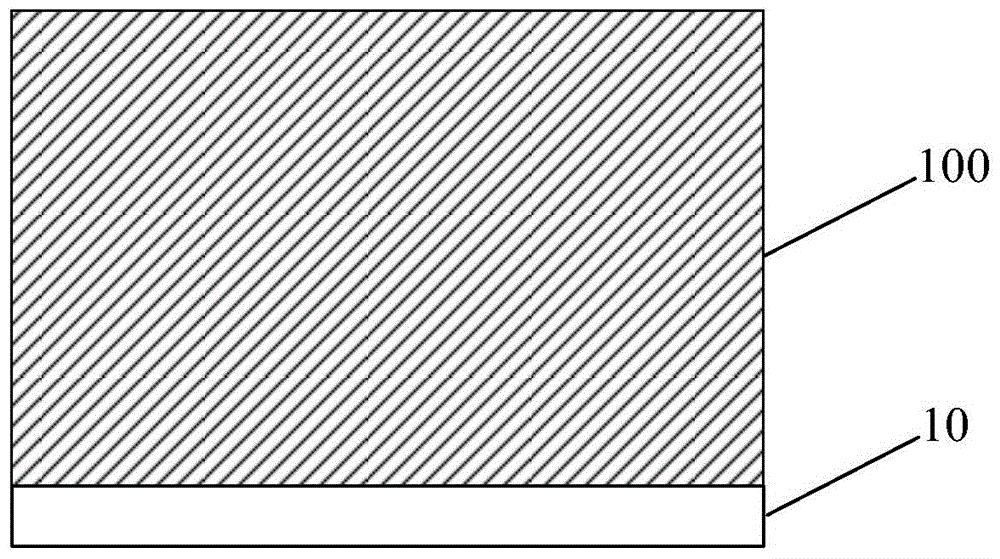

[0052] The metal grains formed by the method of forming the conductive structure in the interconnection structure in the prior art are all small, such as the conductive structure of the metal material formed by the Damascene or Dual Damascene process in the prior art (such as plugs or interconnection lines), the grain size inside the metal material is small, and the small grain size will reduce the conductivity of the copper material itself to a certain extent. The reason is that electrons are transported inside the metal When , the electrons will be scattered to varying degrees every time they encounter the grain boundary. For a fixed-size conductive structure, the smaller the grains, the more grains there are, and the more grain boundaries that electrons encounter during transport.

[0053] To this end, the present invention provides a method for forming an interconnection structure, including: providing a substrate; forming a first metal layer with grains of a first size on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com