SOI high-voltage device provided with stepped shielding groove voltage-resisting structure and double-drain-electrode structure

A technology of withstand voltage structure and high-voltage devices, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as low breakdown voltage and self-heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

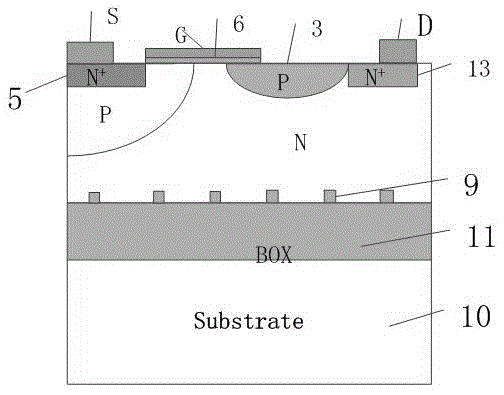

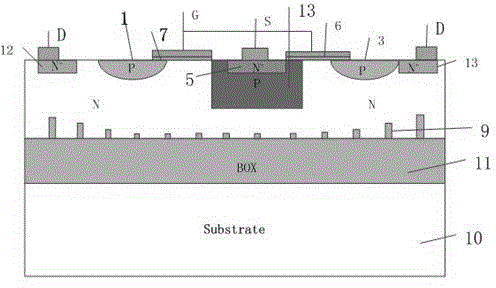

[0017] Embodiment 1: an N-type LDMOS with a ladder-shaped shielding layer structure and a double-drain structure.

[0018] figure 2 It is a schematic structural diagram of an N-type LDMOS with a stepped shielding groove withstand voltage structure in the first embodiment of the present invention, Figure 4 It is a top view of the structure of an N-type LDMOS device with a stepped shielding groove withstand voltage structure in the first embodiment of the present invention.

Embodiment 2

[0019] Embodiment 2: an N-type LDMOS structure with a ladder-shaped shielding layer structure and ring drains and ring gates.

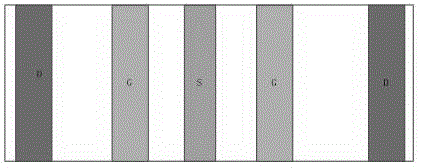

[0020] Figure 5 It is a top view of the structure of an N-type LDMOS device with a stepped shielding groove withstand voltage structure, a ring-shaped drain electrode, and a ring-shaped gate electrode structure in the second embodiment of the present invention. Compared with the double-drain structure, the annular drain and gate design further reduces the lateral electric field in the drift region, and the electric field distribution is more uniform, so the lateral breakdown voltage increases.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com