Separation and recovery method for carbon nanotubes having optical activity and carbon nanotubes having optical activity

A carbon nanotube and optically active technology, which is applied to the separation and recovery of optically active carbon nanotubes and the field of optically active carbon nanotubes, can solve the problems of unresearched CNT optical segregation, and achieve low cost and large-scale processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

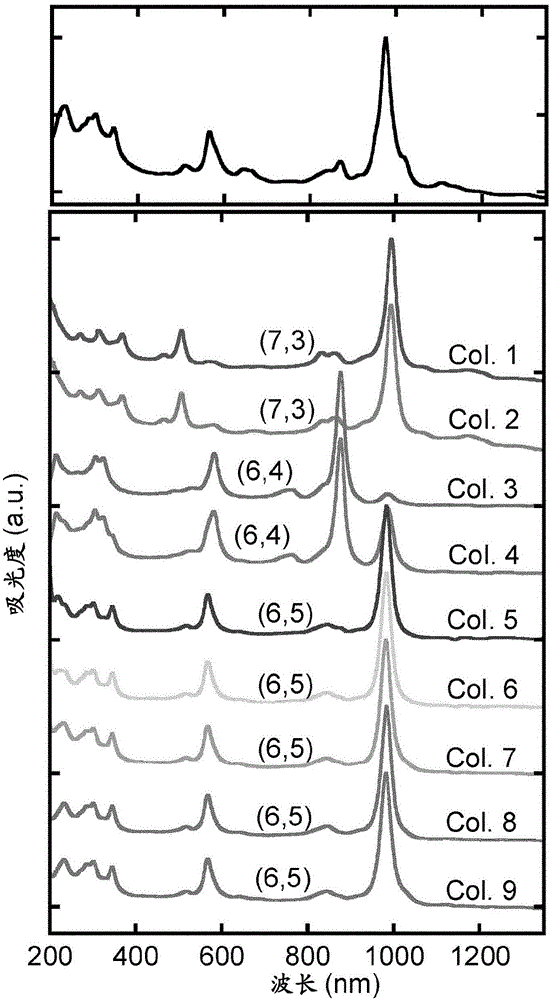

[0107] In this example, the types of (n, m)CNTs contained in the sample were reduced by pre-separation, and single (n, m) CNTs having optical activity were isolated using this sample.

[0108] [Preparation of CNT dispersion liquid]

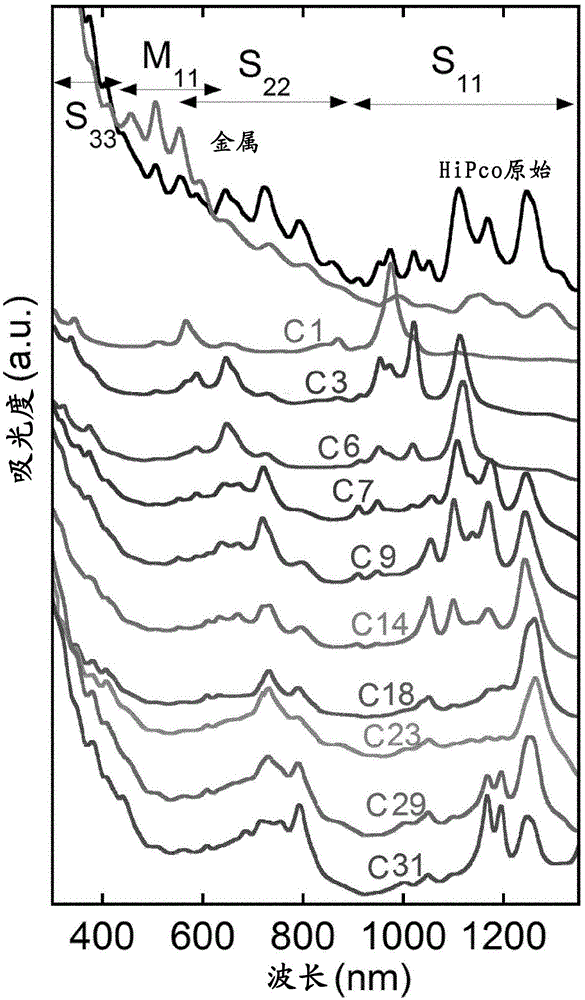

[0109] 2% SDS aqueous solution (100 ml) was added to 100 mg of Hipco-CNT (NanoIntegris, CNT synthesized by chemical vapor phase growth method, diameter 1.0±0.3 nm). This solution was cooled in cold water using a tip type ultrasonic breaker (Sonifier, manufactured by Branson Co., Ltd., tip diameter: 0.5 inch) at an output of 30 W / cm 2 Sonication was performed for 9 hours. The resulting dispersion was subjected to ultracentrifugation (289,000×g, 15 minutes) by ultrasonic treatment, and 90% of the supernatant was recovered. This solution was referred to as a CNT dispersion liquid.

[0110] [pre-separation]

[0111] Gel beads (SEPHACRYLS-200HR, GE healthcare) were used as column carriers. The outlet of a plastic syringe with a length of 8 cm and ...

Embodiment 2

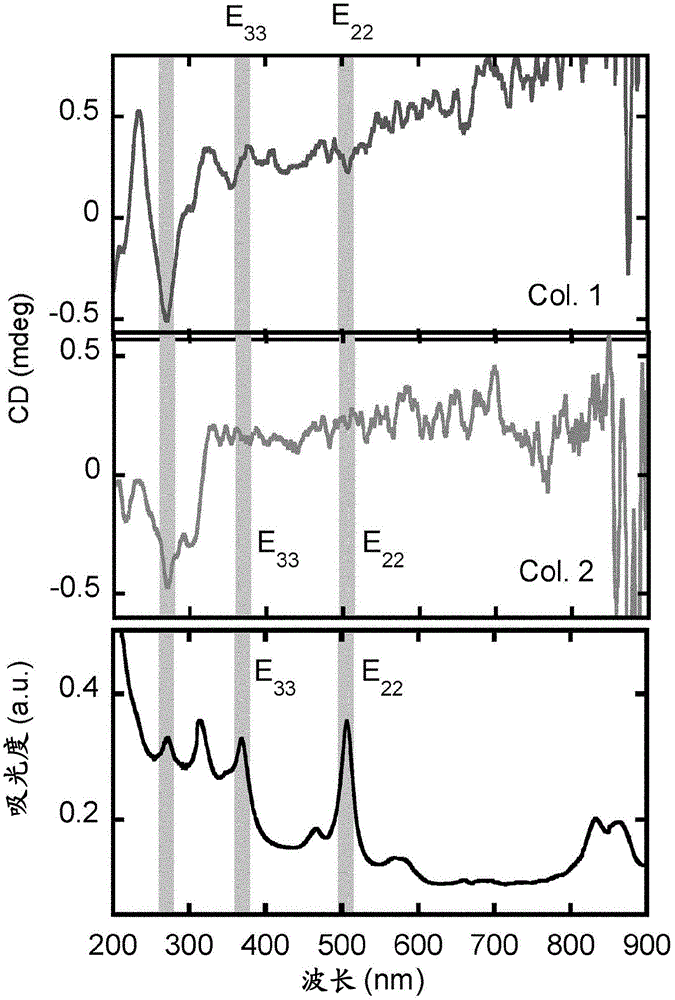

[0133] In this example, using the optically inert (6,5) CNT obtained in Col. segregation.

[0134] show the result in Figure 9 . In the figure, the upper layer is before separation, and the lower layer is after separation.

[0135] Depend on Figure 9 It was found that optically active CNTs can be separated by performing the same separation again using optically inactive CNTs.

Embodiment 3

[0137] In this example, by optimizing the dispersion conditions and separation parameters of CNTs, the optical resolution of (5,4) CNTs was performed without performing pre-separation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com