An automatic continuous production process for processing green tea from large-leaf tea

A large-leaf tea planting and production process technology, which is applied in tea treatment before extraction, can solve the problems of no relevant reports on the production process, and achieve the effects of shortening the time of greening, maintaining nutritional components, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

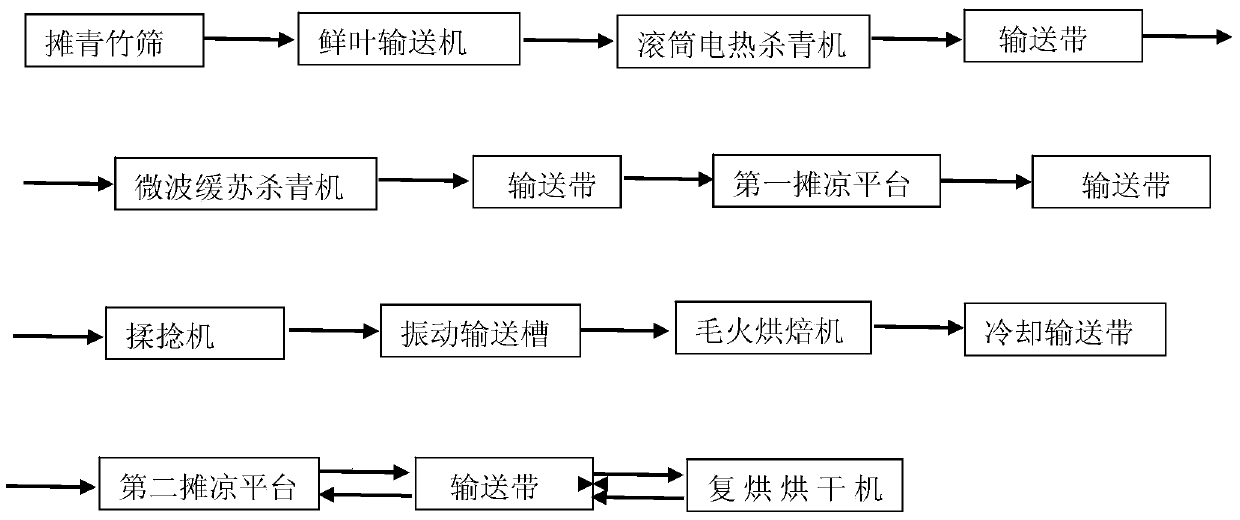

Method used

Image

Examples

Embodiment 1

[0031] Taking Guangxi Dayezhongcha Fuding Dahao No. 6 as tea raw material, adopting the process of the present invention to automatically and continuously process famous and high-quality green tea, the specific steps are as follows:

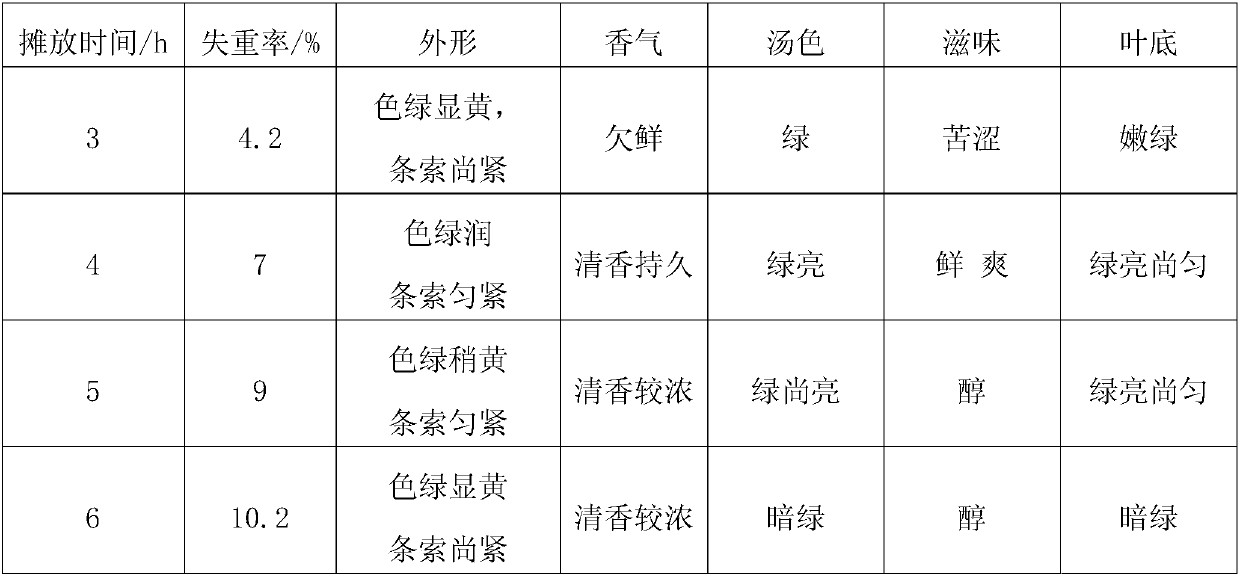

[0032] (1) Spread green: Spread the single buds of the picked big-leaf tea evenly on the bamboo sieve, the thickness of which is 2-3cm, the indoor temperature is 18°C, and the relative humidity is 50%. Spread out in the way of wind blowing, and spread out for 3h, 4h, 5h, 6h respectively, and the single bud weight loss rate is respectively 4.2%, 7%, 9%, 10.3% to get the green leaves; processing as follows;

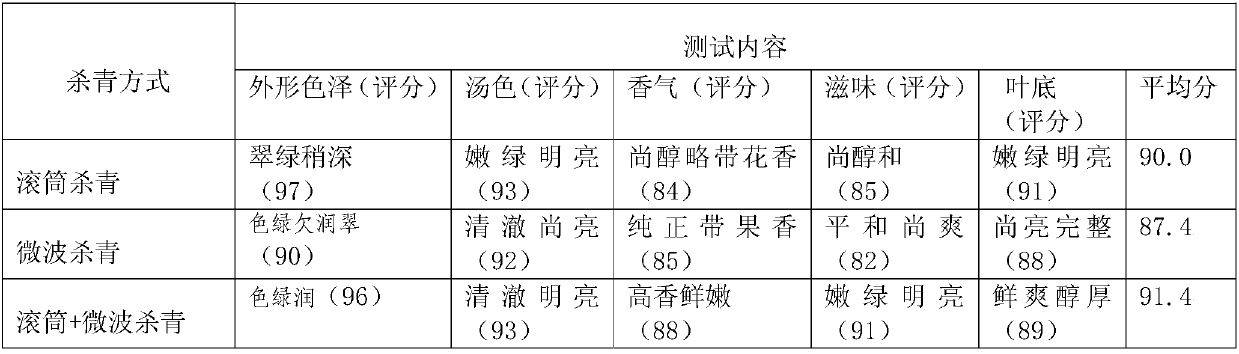

[0033] (2) Finishing: Send green leaves through the fresh leaf conveyor to the drum electric heating machine, set the temperature inside the drum to 300°C, and start feeding when the temperature of the feed inlet rises to 150°C, and the feeding and discharging time is controlled at 80 seconds , the amount of leaves per hour is set to 10 kg, a...

Embodiment 2

[0047] Taking Guangxi Dayezhongcha Fuyun No. 6 as the tea raw material, adopting the process of the present invention to automatically and continuously process famous and high-quality green tea, the specific steps are as follows:

[0048] (1) Spread green: Spread the single buds of the picked big-leaf tea evenly on the bamboo sieve, the thickness of which is 2-3cm, the indoor temperature is 22°C, and the relative humidity is 60%. Spread out in the way of blowing air, so that the single bud weight loss rate is 9% and the green leaves are spread out;

[0049] (2) Finishing: Send green leaves through the fresh leaf conveyor to the drum electric heating machine, set the temperature inside the drum to 350°C, and start feeding when the temperature of the feed inlet rises to 180°C, and the feeding and discharging time is controlled at 70 seconds , the amount of leaves per hour is set to 15 kg, and the leaves must be killed;

[0050] (3) Microwave simmering: After the drum electric h...

Embodiment 3

[0063] Taking Guangxi Dayezhongcha Fuyun No. 6 as the tea raw material, adopting the process of the present invention to automatically and continuously process famous and high-quality green tea, the specific steps are as follows:

[0064] (1) Spread green: Spread the single buds of the picked big-leaf tea evenly on the bamboo sieve, the thickness of which is 2-3cm, the indoor temperature is 20°C, and the relative humidity is 55%. Spread out in the way of blowing air, so that the single bud weight loss rate is 8% and the green leaves are spread out;

[0065] (2) Finishing: Send green leaves through the fresh leaf conveyor to the drum electric heating machine, set the temperature inside the drum to 320°C, and start feeding when the temperature of the feed inlet rises to 160°C, and the feeding and discharging time is controlled at 75 seconds , the amount of leaves per hour is set to 12 kg, and the leaves must be killed;

[0066] (3) Microwave simmering: After the drum electric h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com