Enzyme silk noodle preparation method, wherein alum is replaced by starch branched chain hydrolytic enzymes

A production method, hydrolytic enzyme technology, applied in the preparation of vermicelli, enzymatic vermicelli production field, to achieve the effect of good food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

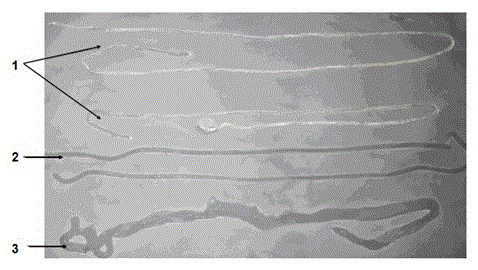

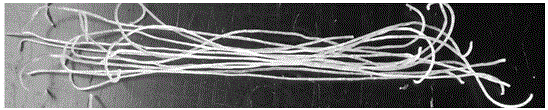

Image

Examples

Embodiment 1

[0054] Embodiment 1: make pure potato starch vermicelli with starch pullulan hydrolase

[0055] The specific production steps are as follows:

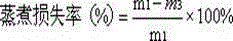

[0056] The first step of emulsification of starch: Weigh 100g of potato starch, add 50-200mL of warm water (the water temperature should be controlled at 40-55°C, and cannot reach or exceed the gelatinization temperature of starch), and stir until the starch is completely dispersed. The second step of gelatinization: add boiling water with 4-10 times the volume of starch, stir quickly until it is completely gelatinized, add edible salt (sodium chloride) equivalent to about 0.1% of the total amount of water added, and stir to dissolve. The temperature of the gelatinized liquid is lowered to the temperature suitable for the action of the amylopectin hydrolase. Among them, the suitable action temperature of pullulanase 1, pullulanase 2 and pullulanase 3 is 50-65°C, and the suitable action temperature of isoamylase 1 is 40-50°C. Accordin...

Embodiment 2

[0073] Embodiment 2: make pure sweet potato and pure tapioca vermicelli with starch pullulan hydrolase

[0074]Take sweet potato starch, cassava starch as raw material to add pullulanase I to make the specific preparation steps of vermicelli with embodiment 1. The results are shown in Table 6~9.

[0075] Table 6 Effect of different enzyme amounts of pullulanase 1 on the quality of pure sweet potato starch vermicelli

[0076]

[0077] Table 7 Effect of different enzyme amounts of pullulanase 1 on the quality of cassava starch vermicelli

[0078]

[0079] It can be seen from Table 6 that without the addition of pullulanase, when making vermicelli with sweet potato starch as raw material, the viscosity of vermicelli sticks is very high in the silk-making stage, and the vermicelli sticks will stick to each other, that is, serious drawing will occur Phenomenon, the broken rate of the vermicelli made is very high, reaching 19%, and the quality is far from that of the vermice...

Embodiment 3

[0082] Embodiment 3: make cornstarch vermicelli with starch pullulan hydrolase

[0083] Corn starch is one of the starches with the largest output in my country and the cheapest price on the market at present. When using the production method of Example 1 and using pure corn starch as raw material to make vermicelli, no matter adding alum or adding pullulanase, vermicelli strips in the silk-making stage All there is rotten paste phenomenon in boiling water, can't become bar, therefore all can't make vermicelli using pure cornstarch alone. According to this, the following cornstarch vermicelli productions are made by mixing cornstarch with other starches. First mix cornstarch and potato starch, the mixing ratio is cornstarch:potato starch 10:3, 10:5, 10:6, 10:10, 10:20, 10:30 (both mass ratios), and then respectively The above-mentioned mixed powder was made into vermicelli according to the production steps of Example 1 without adding any additives, adding alum as an additive a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com