Lipidosome nucleic acid vaccine adjuvant as well as preparation method and application thereof

A vaccine adjuvant and body nucleic acid technology, applied in the directions of liposome delivery, antiviral agents, pharmaceutical formulations, etc., can solve the problems of low effective delivery rate, weak immune response, no immune response, etc., and achieves simplified preparation process, Improves immune response and improves presentation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The preparation of liposome nucleic acid vaccine adjuvant comprises the steps:

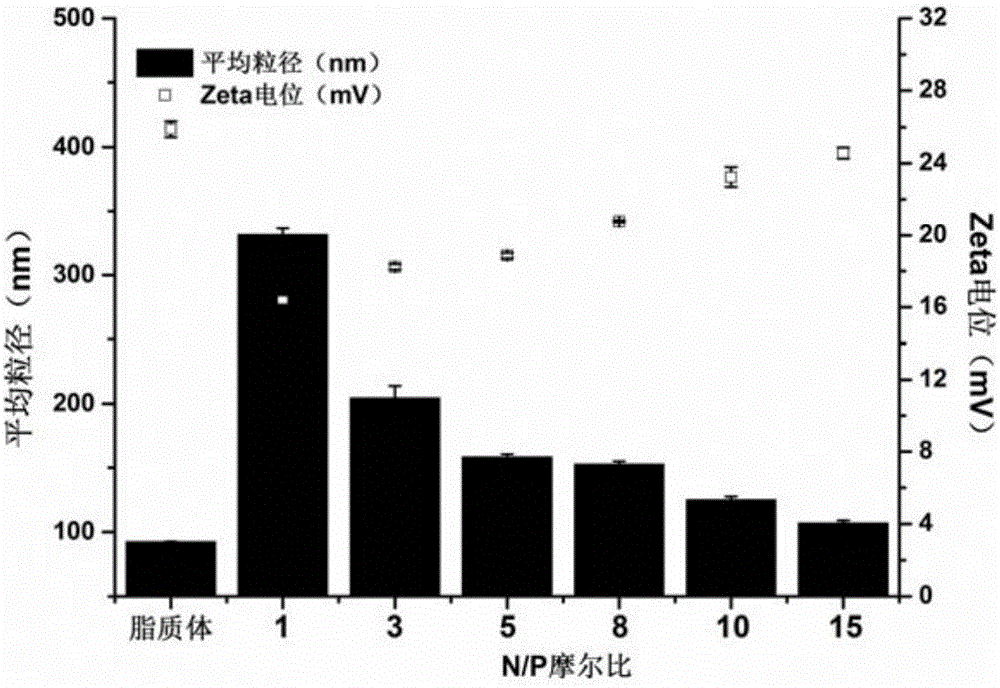

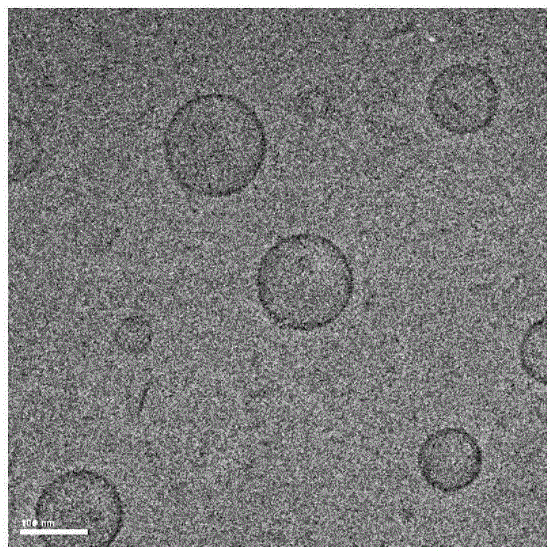

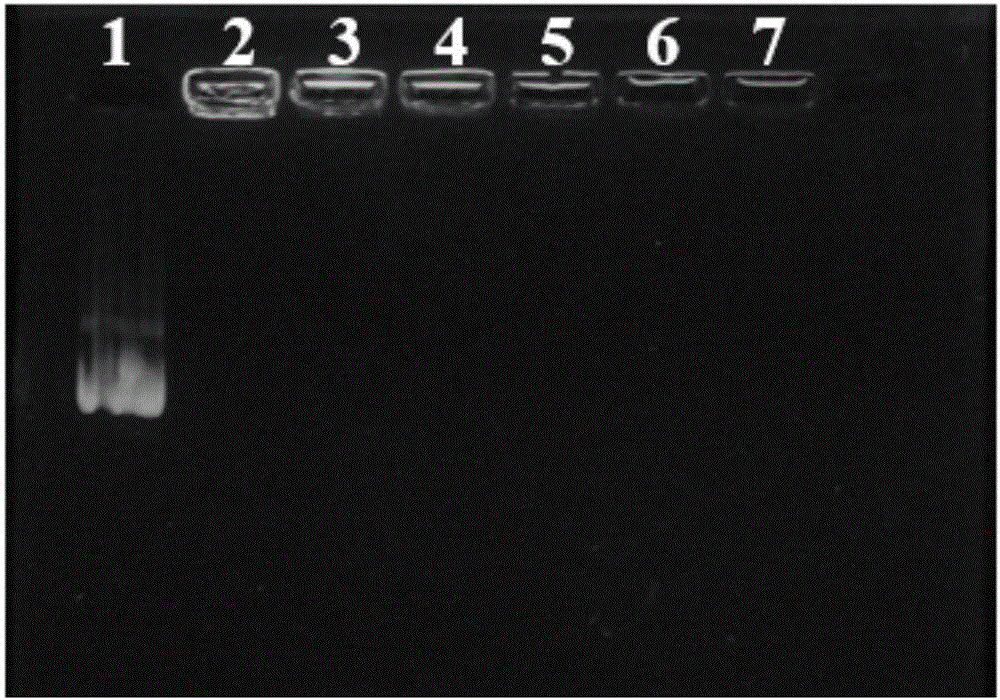

[0054] Weigh cationic liposome DOTAP55.84mg, cholesterol 30.932mg, DSPE-PCB2061.46mg and DSPE-PCB20-mannose 26.34mg in a 100mL round bottom flask, add chloroform to fully dissolve, at 45°C, speed 122rpm / min The chloroform was removed by rotary evaporation under reduced pressure to form a thin film, and dried overnight in a vacuum oven to remove residual chloroform. Then, 10 mL of sterile phosphate buffered saline (1×PBS, pH=7.4) was added to the flask, and the flask was sonicated at 37° C. for 30 min to obtain a light yellow translucent emulsion. Add the emulsion into a high-pressure homogenizer, and under the condition of a pressure of 100 MPa, homogenize under high pressure for 3 times to prepare the liposome nucleic acid vaccine adjuvant.

Embodiment 2

[0056] Weigh cationic liposome DDAB55.84mg, 1,2-oleoylphosphatidylethanolamine 30.932mg, DG-PCB2071.556mg and DG-PCB20-folate 107.326mg in a 100mL round bottom flask, add chloroform to fully dissolve, and Under the conditions of 55° C. and 152 rpm / min, the organic solvent was evaporated under reduced pressure to form a thin film, and dried overnight in a vacuum oven to remove residual chloroform. Then, 10 mL of sterile phosphate buffered saline (1×PBS, pH=7.4) was added to the flask, and the flask was sonicated at 37° C. for 60 min to obtain a light yellow translucent emulsion. Add the emulsion into a high-pressure homogenizer, and under the condition of a pressure of 100 MPa, homogenize under high pressure for 3 times to prepare a novel liposome nucleic acid vaccine adjuvant.

Embodiment 3

[0058] Weigh cationic liposome DOGS55.84mg, distearoylphosphatidylethanolamine 30.932mg, DC-PCB50107.318mg and DC-PCB50-RGD160.977mg in a 100mL round-bottomed flask, add chloroform to fully dissolve, and place at 60℃ , under the condition of rotating speed 182rpm / min, the organic solvent was removed by rotary evaporation under reduced pressure to form a thin film, and dried overnight in a vacuum oven to remove residual chloroform. Then, 10 mL of sterile phosphate buffered saline (1×PBS, pH=7.4) was added to the flask, and the flask was sonicated at 37° C. for 1 h to obtain a light yellow translucent emulsion. Add the emulsion into a high-pressure homogenizer, and under the condition of a pressure of 100 MPa, homogenize under high pressure for 3 times to prepare a novel liposome nucleic acid vaccine adjuvant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transfection efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com