a kind of wo 3 /tiof 2 Preparation method of composite visible light catalyst

A catalyst and visible light technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as high energy consumption and complex process, and achieve low energy consumption, good degradation performance, and good application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

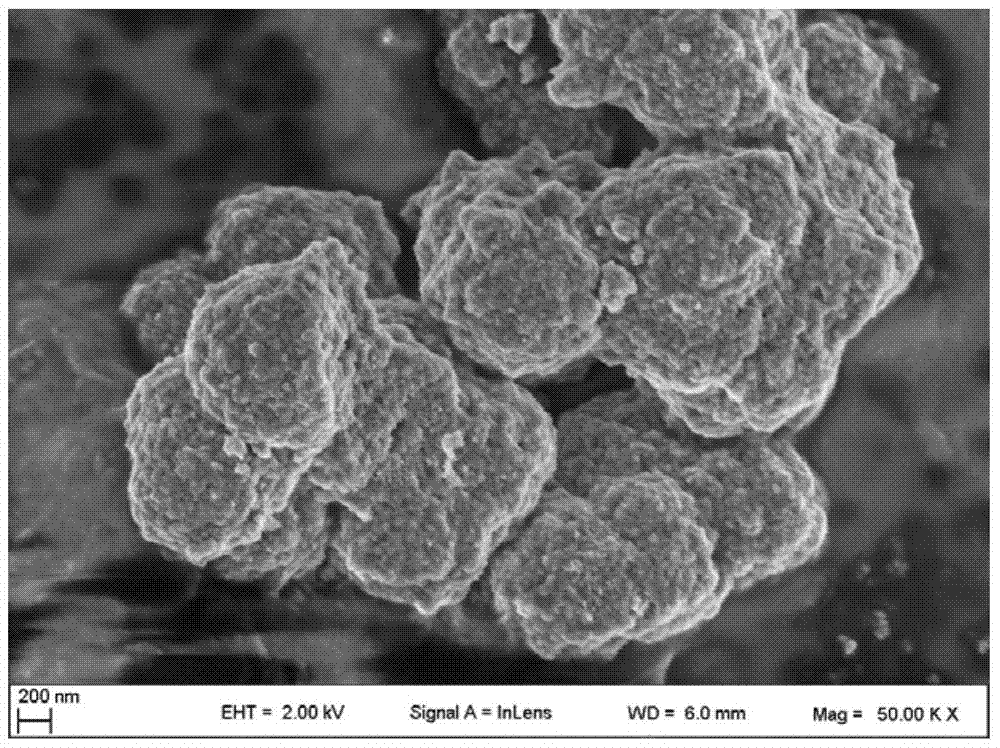

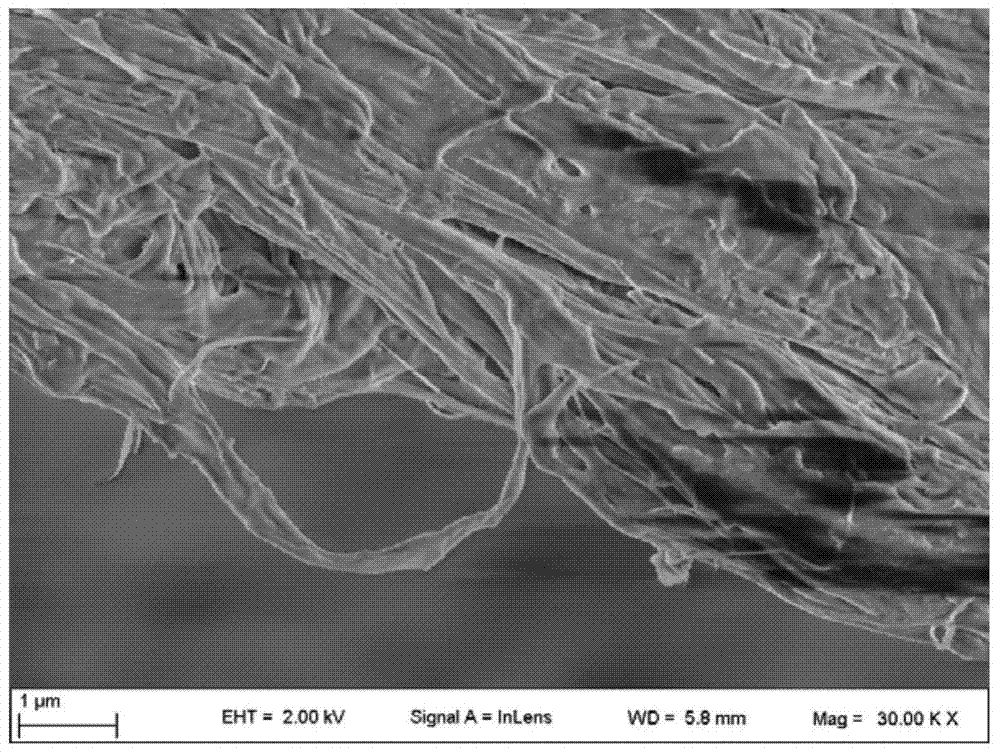

[0021] This embodiment prepares WO 3 / TiOF 2 The method of composite visible light catalyst is realized by the following steps:

[0022] (1) Measure absolute ethanol, add it to butyl titanate according to the ratio of butyl titanate to absolute ethanol volume ratio of 1.15:1, and mix well to obtain A solution;

[0023] (2) Take deionized ethanol and HF and add them into deionized water so that the volume ratio of deionized water to deionized ethanol and HF is 1:0.169:0.112 to obtain solution B;

[0024] (3) Under the condition of heating at a constant temperature of 60°C, add solution B to solution A drop by drop, so that the molar ratio of butyl titanate in mixed solution A to deionized water in mixed solution B is 1:100, and the dropping speed Controlled at 3 drops per second, stirred at a constant speed of 650r / min for 2 hours to obtain TiOF 2 gel;

[0025] (4) Place the aged TiOF at room temperature for 2 days in the dark. 2 Put it in an oven and dry it at 100°C, wash...

Embodiment 2

[0029] This embodiment prepares WO 3 / TiOF 2 The method of composite visible light catalyst is realized by the following steps:

[0030] (1) Measure absolute ethanol, add it to butyl titanate according to the ratio of butyl titanate to absolute ethanol volume ratio of 1:1, and mix well to obtain A solution;

[0031] (2) Take deionized ethanol and HF and add them into deionized water so that the volume ratio of deionized water to deionized ethanol and HF is 1:0.1:0.1 to obtain solution B;

[0032] (3) Under the condition of heating at a constant temperature of 50°C, add solution B to solution A dropwise, so that the molar ratio of butyl titanate in mixed solution A to deionized water in mixed solution B is 1:90, and the dropping speed is controlled At 2 drops per second, 500r / min constant temperature magnetic stirring for 3 hours, TiOF 2 Gel, aged at room temperature for 1 day;

[0033] (4) The aged TiOF 2 The gel was moved to a blast drying oven at 80°C and dried at a const...

Embodiment 3

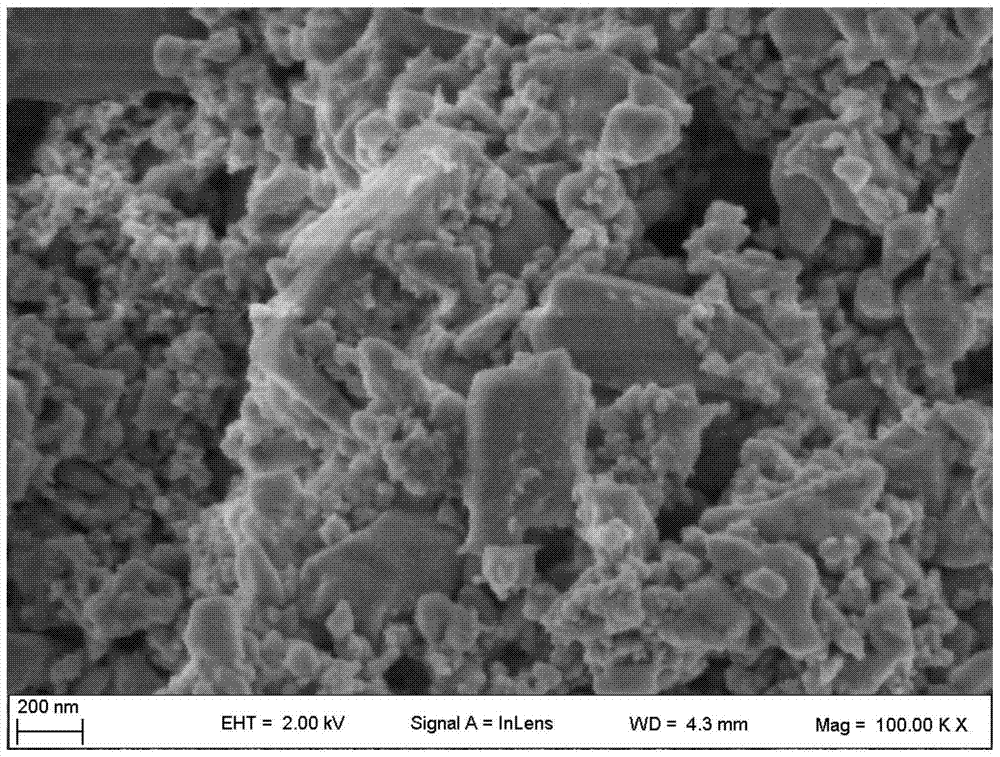

[0037] This embodiment prepares WO 3 / TiOF 2 The method of composite visible light catalyst is realized by the following steps:

[0038] (1) Measure absolute ethanol, add it to butyl titanate according to the ratio of butyl titanate to absolute ethanol volume ratio of 1.2:1, and mix well to obtain A solution;

[0039] (2) Take deionized ethanol and HF and add them into deionized water so that the volume ratio of deionized water, dehydrated ethanol and HF is 1:0.2:0.2 to obtain solution B;

[0040] (3) Under the condition of constant temperature heating at 58°C, add solution A to solution B dropwise, so that the molar ratio of butyl titanate in mixed solution A to deionized water in mixed solution B is 1:105, and the dropping speed is controlled At 3 drops per second, 800r / min constant temperature magnetic stirring for 1 hour, TiOF 2 Gel, aged at room temperature for 3 days;

[0041] (4) The aged TiOF 2 The gel was moved to a blast drying oven at 90°C and dried at a consta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com