Foam septic tank

A septic tank and body technology, which is applied in the field of foaming septic tanks, can solve the problems of increasing the workload of sewage treatment plants, destroying the water environment of surrounding rivers and lakes, and lacking technical content, and achieves light weight, increased residence time, and light products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

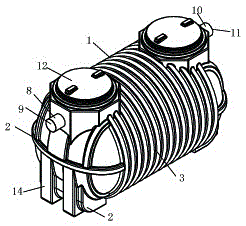

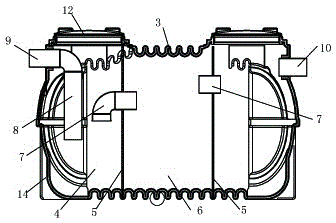

[0015] Combine below Figure 1 to Figure 3 Specific description embodiment:

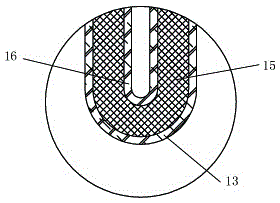

[0016] The foaming septic tank includes a body 1, the body 1 includes an outer surface layer, a middle layer and an inner layer, the outer surface layer is a PE layer 13, the middle layer is a foam layer 15, and the inner layer is a PE layer. Layer 16; the outer surface of the two ends of the body 1 is provided with a square groove reinforcement rib 2, and the outer surface of the middle section of the body 1 is provided with a corrugated reinforcement rib 3; the body 1 is provided with a septic tank The pool room 4 and the septic tank room 4 are provided with several partitions 5, the partitions 5 divide the septic tank room 4 into several functional room areas 6, and the adjacent functional room areas 6 are communicated through pipes 7; The functional room area 6 at one end of the body communicates with the outside of the body 1 through a water inlet pipe 8 forming a water inlet 9, and the functio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com