Process for recovering maleic anhydride using diisobutyl hexahydrophthalate as solvent

A technology of diisobutyl phthalate and hexahydrogenation, which is applied in organic chemistry and other fields, can solve problems such as increasing production costs, and achieve the effects of weak hydrophilicity, low saturated vapor pressure, and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

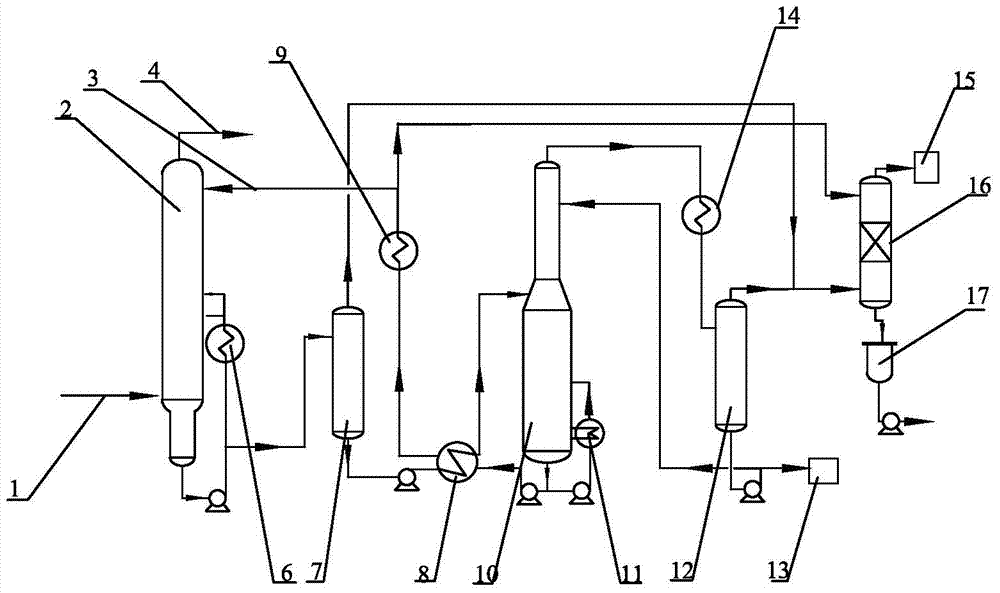

[0040] A kind of technique that reclaims maleic anhydride with diisobutyl hexahydrophthalate as solvent:

[0041](1) The content of maleic anhydride in the n-butane oxidation reaction gas is 0.9mol%. The reaction gas is fed from the lower part of the absorption tower 2 through the reaction gas pipeline 1, and the DIBE poor solvent is fed from the absorption tower 2 tower through the poor solvent pipeline 3. Feed, the two are countercurrently contacted in the absorption tower 2, and the DIBE poor solvent absorbs and cools the maleic anhydride. The lean solvent feed temperature is 45° C., and m (lean solvent) / m (reaction gas) is 0.05. n-butane, CO, CO discharged from the top of absorption tower 2 2 , nitrogen and other VOC tail gases are discharged to the tail gas treatment system by the tail gas pipeline 4, and what is obtained at the bottom of the tower is the rich DIBE solvent that has absorbed maleic anhydride.

[0042] (2) The temperature of the reaction gas is 130°C; the...

Embodiment 2

[0053] A kind of technique that reclaims maleic anhydride with diisobutyl hexahydrophthalate as solvent:

[0054] (1) The content of maleic anhydride in the n-butane oxidation reaction gas is about 1.8mol%. The reaction gas is fed from the lower part of the absorption tower 2 through the reaction gas pipeline 1, and the DIBE poor solvent is fed from the absorption tower 2 through the poor solvent pipeline 3. The top feed, the two are countercurrently contacted in the absorption tower 2, and the DIBE poor solvent absorbs and cools the maleic anhydride. The lean solvent feed temperature is 80° C., and m (lean solvent) / m (reaction gas) is 0.5. n-butane, CO, CO discharged from the top of absorption tower 2 2 , nitrogen and other VOC tail gases are discharged to the tail gas treatment system by the tail gas pipeline 4, and what is obtained at the bottom of the tower is the rich DIBE solvent that has absorbed maleic anhydride.

[0055] (2) The temperature of the reaction gas is 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com