Preparation method for polyurethane air filter element of car

An air filter element and polyurethane technology, which is applied in the chemical industry, can solve the problems of complex preparation process, difficulty in taking into account mechanical strength and flexibility, etc., and achieve the effects of simple process, good comprehensive mechanical properties, good application prospects and promotion value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

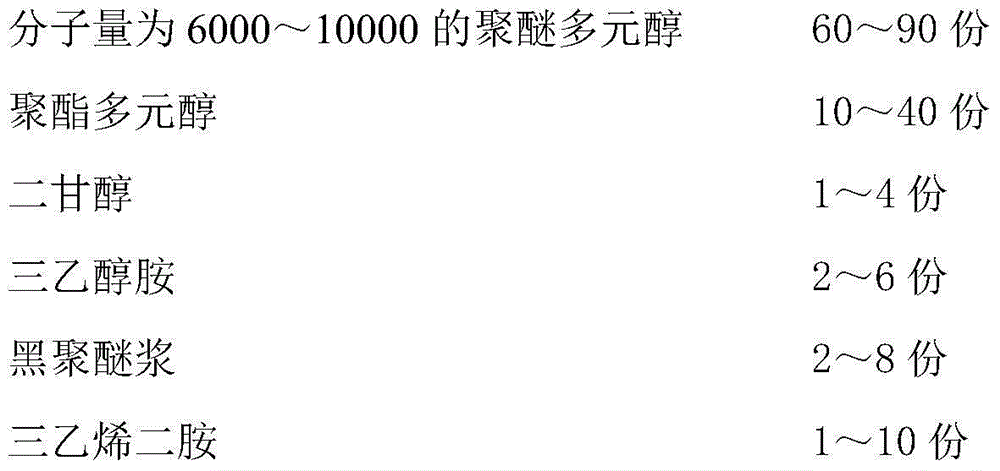

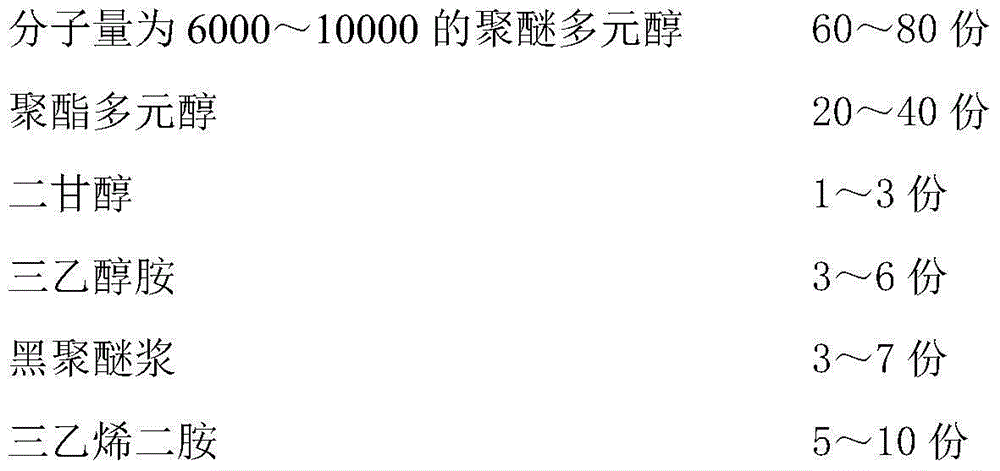

[0041] 1. Take 90kg of polyether polyol with a molecular weight of about 6000, 20kg of polyester polyol, 2kg of diethylene glycol, 3kg of triethanolamine, 8kg of black polyether pulp, and 2kg of triethylenediamine, and put the above raw materials into the reaction kettle. React at ℃ for 2 hours to prepare liquid A;

[0042] 2. Put 70kg of modified polymethyl polyphenyl isocyanate and 30kg of polyether polyol into the reaction kettle, and react at 60°C for 7 hours to prepare liquid B;

[0043] 3. Inject liquid A and liquid B into tanks A and B of the glue injection machine respectively. The temperature of tank B is 30°C. After selecting the air filter mold, start the machine to inject glue. The mass ratio of liquid A to liquid B is 100:30;

[0044] 4. Immediately insert the filter paper core after injecting the glue, and release the mold after 8 minutes to obtain a polyurethane automobile air filter element.

Embodiment 2

[0046] 1. Take 60kg of polyether polyol with a molecular weight of about 10000, 40kg of polyester polyol, 1kg of diethylene glycol, 2kg of triethanolamine, 2kg of black polyether pulp, and 4kg of triethylenediamine, and put the above raw materials into the reaction kettle. React at ℃ for 3 hours to prepare liquid A;

[0047] 2. Put 80kg of modified polymethyl polyphenyl isocyanate and 30kg of polyether polyol into the reaction kettle, and react at 100°C for 8 hours to prepare liquid B;

[0048] 3. Inject liquid A and liquid B into tanks A and B of the glue injection machine respectively. The temperature of tank B is 20°C. After selecting the air filter mold, start the machine to inject glue. The mass ratio of liquid A to liquid B is 100:20;

[0049] 4. Immediately insert the filter paper core after injecting the glue, and release the mold after 8 minutes to obtain a polyurethane automobile air filter element.

Embodiment 3

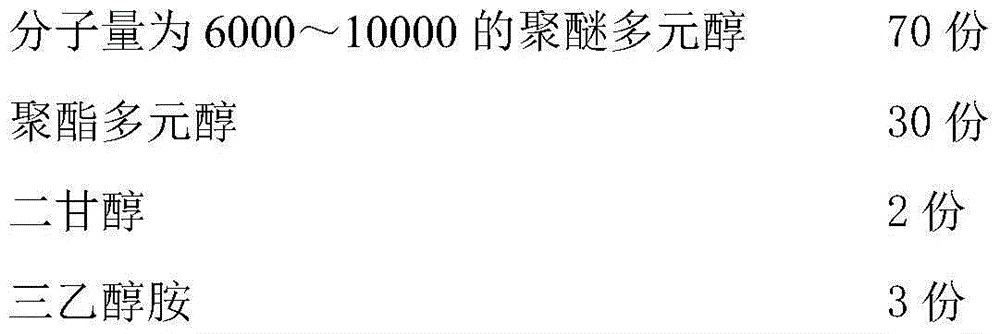

[0051]1. Take 70kg of polyether polyol with a molecular weight of about 8000, 30kg of polyester polyol, 2kg of diethylene glycol, 3kg of triethanolamine, 5kg of black polyether pulp, and 8kg of triethylenediamine, and put the above raw materials into the reaction kettle. React at ℃ for 3 hours to prepare liquid A;

[0052] 2. Put 60 kg of modified polymethyl polyphenyl isocyanate and 40 kg of polyether polyol into the reaction kettle, and react at 80°C for 5 hours to prepare liquid B;

[0053] 3. Inject liquid A and liquid B into tanks A and B of the glue injection machine respectively. The temperature of tank B is 10°C. After selecting the air filter mold, start the machine to inject glue. The mass ratio of liquid A to liquid B is 100:25;

[0054] 4. Immediately insert the filter paper core after injecting the glue, and release the mold after 7 minutes to obtain a polyurethane automobile air filter element.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com