Novel method for producing plate springs

A production method and leaf spring technology, applied in the field of leaf spring production, can solve the problems of low output, labor consumption, labor cost increase, etc., and achieve the effects of increasing output, reducing labor, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following examples will further describe the specific implementation of the present invention. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

[0019] A novel production method for manufacturing leaf springs, the production method is:

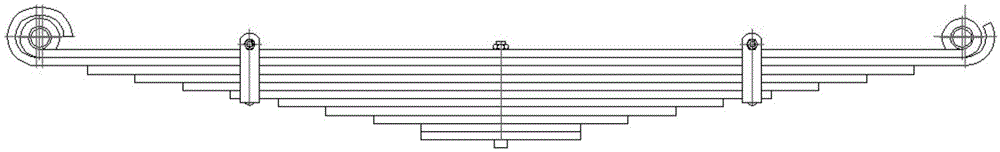

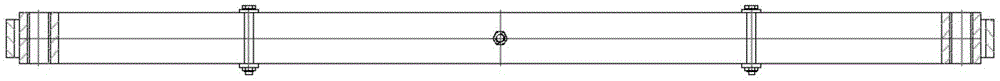

[0020] Step A: Stack the leaf springs together in a certain order for preheating, and the leaf springs are initially formed, such as Figure 1-2 shown;

[0021] Step B: Fix the quenching die on the quenching machine in advance, and put it into the leaf spring forming quenching die after the initial forming of the leaf spring, and perform quenching at the same time; the inner wall of the quenching die is equipped with a temperature sensor to detect the quenching die in real time temperature.

[0022] Step C: During the quenching process, a turbine is placed at the bottom of the quenched hard film of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com