one to add ceo 2 iron-based cr 3 c 2 Laser cladding coating and preparation method thereof

A laser cladding and coating technology, which is applied in the coating, metal material coating process, etc., can solve the problems of poor formability and cladding performance, easy to generate pores and cracks, and affect the performance of iron-based alloy coatings, etc. , to achieve the effects of good wear resistance and toughness, uniform and refined structure, optimized quantity and distribution shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

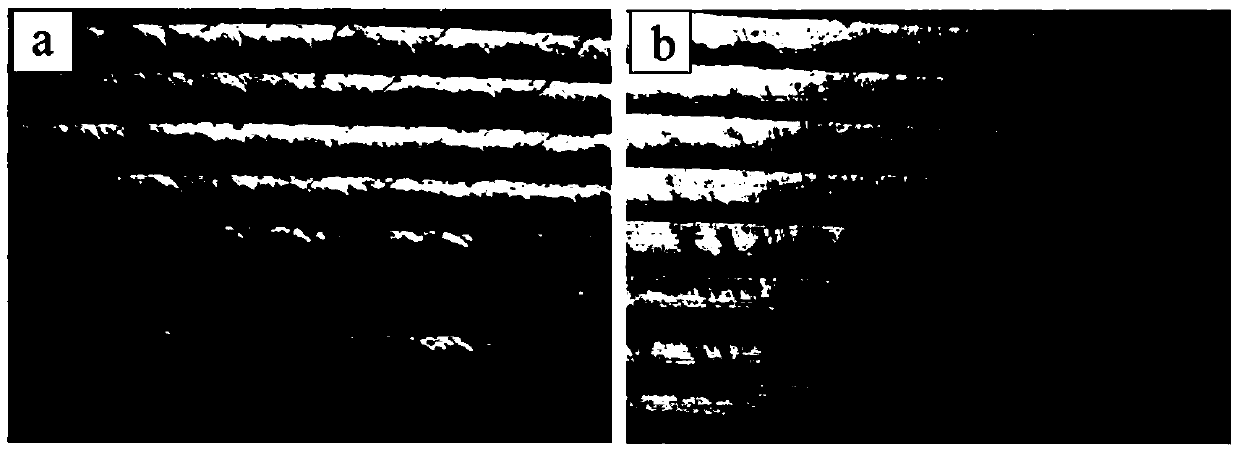

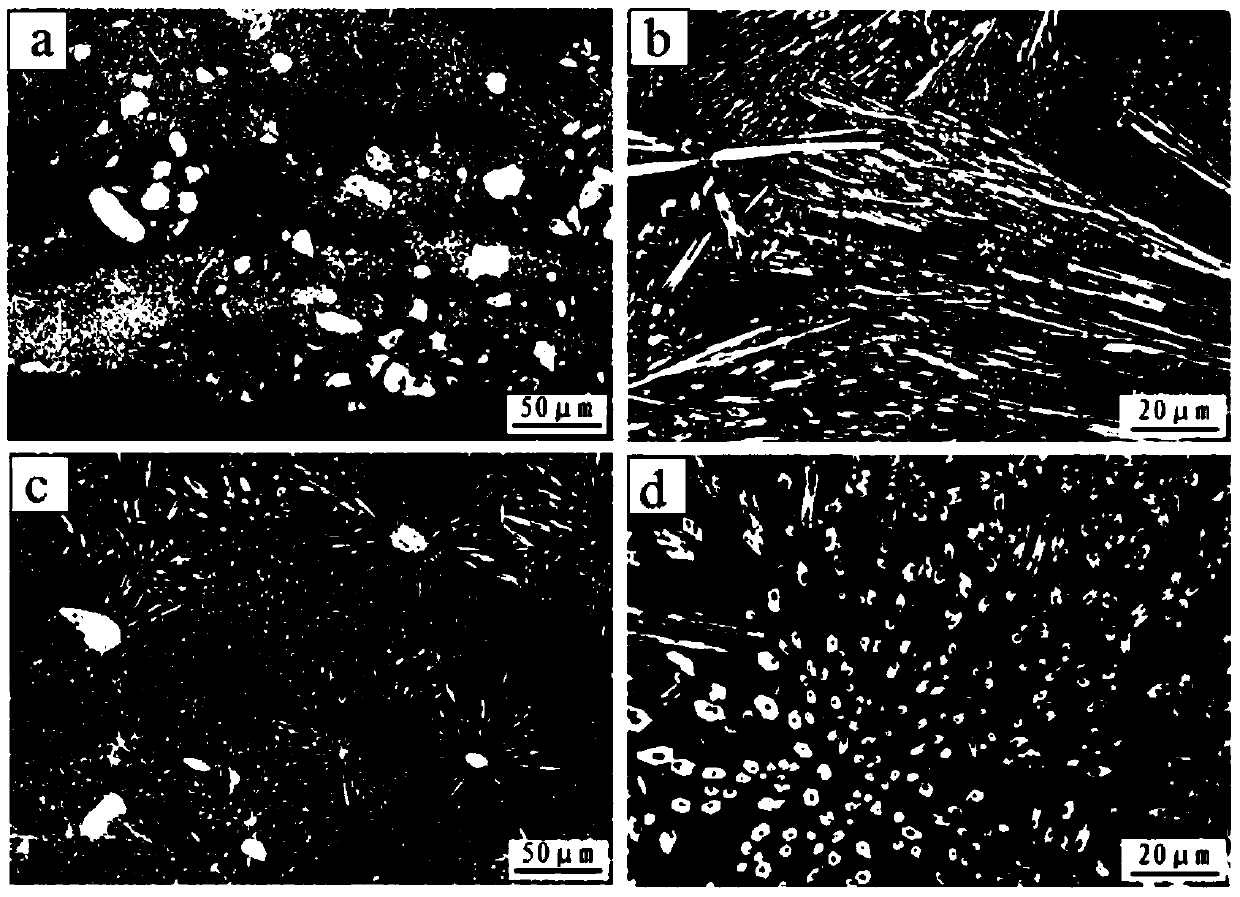

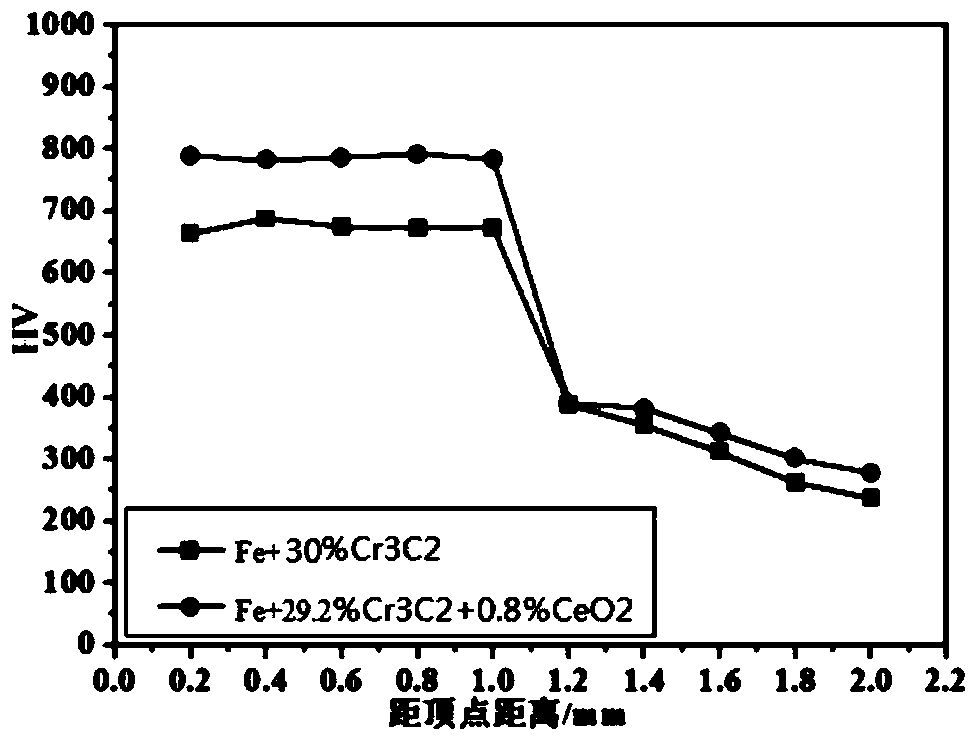

[0049] A kind of adding CeO of this embodiment 2 Fe-based Cr 3 C 2 The laser cladding coating is prepared by laser cladding after mixing the following mass percentage components uniformly: 70% iron-based self-fluxing alloy powder, Cr 3 C 2 Alloy powder 29.2% and CeO 2 Powder 0.8%. Wherein, the above-mentioned Fe-based self-fluxing alloy powder is composed of the following components in mass percentage: C0.09%, Cr15%, Ni5%, Si2.8%, B1.0%, Mo0.5%, Fe is the balance, And the particle size of the Fe-based self-fluxing alloy powder is about 70 μm. Cr 3 C 2 The alloy powder is Ni, Cr-Cr 3 C 2 Composite powder, where Cr 3 C 2 Cr in alloy powder 3 C 2 The mass percentage content is 85%, and the Cr 3 C 2 In the alloy powder, the powder with a particle size of 50 μm to 80 μm accounts for Cr 3 C 2 The percentage of the total mass of the alloy powder is 60%, and the powder with a particle size of 80 μm to 110 μm accounts for Cr 3 C 2 The percentage of the total mass of ...

Embodiment 2

[0084] A kind of adding CeO of this embodiment 2 Fe-based Cr 3 C 2 The laser cladding coating is prepared by laser cladding after mixing the following mass percentage components uniformly: 70% iron-based self-fluxing alloy powder, Cr 3 C 2 Alloy powder 29% and CeO 2 Powder 1%. Wherein, the above-mentioned Fe-based self-fluxing alloy powder is composed of the following components in mass percentage: C0.07%, Cr17%, Ni6%, Si2.5%, B0.9%, Mo0.6%, Fe is the balance, And the particle size of the Fe-based self-fluxing alloy powder is about 120 μm. Cr 3 C 2 The alloy powder is Ni, Cr-Cr 3 C 2 Composite powder, where Cr 3 C 2 Cr in alloy powder 3 C 2 The mass percentage content is 85%, and the Cr 3 C 2 In the alloy powder, the powder with a particle size of 50 μm to 80 μm accounts for Cr 3 C 2 The percentage of the total mass of the alloy powder is 60%, and the powder with a particle size of 80 μm to 110 μm accounts for Cr 3 C 2 The percentage of the total mass of the...

Embodiment 3

[0096] A kind of adding CeO of this embodiment 2 Fe-based Cr 3 C 2 The laser cladding coating is prepared by laser cladding after uniformly mixing the following components by mass percentage: 65% iron-based self-fluxing alloy powder, Cr 3 C 2 Alloy powder 34% and CeO 2 Powder 1%. Wherein, the above-mentioned Fe-based self-fluxing alloy powder is composed of the following components in mass percentage: C0.08%, Cr18%, Ni6.5%, Si2.0%, B0.7%, Mo0.6%, Fe is more than The amount, and the particle size of the Fe-based self-fluxing alloy powder is about 60 μm. Cr 3 C 2 The alloy powder is Ni, Cr-Cr 3 C 2 Composite powder, where Cr 3 C 2 Cr in alloy powder 3 C 2 The mass percentage content is 85%, and the Cr 3 C 2 In the alloy powder, the powder with a particle size of 50 μm to 80 μm accounts for Cr 3 C 2 The percentage of the total mass of the alloy powder is 60%, and the powder with a particle size of 80 μm to 110 μm accounts for Cr 3 C 2 The percentage of the tota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com